mine conveyor belt slippage protection

what should i now about conveyor on mining

Mine Conveyor Belt Slippage Protection . Conveyor belt slippage can be a serious safety hazard in mines The friction from slippage causes heat which can result in fires To prevent conveyor belt fires, a. Contact Supplier; gypsum belt conveyor,gypsum conveying machine.

CONVEYOR MANUFACTURERS ASSOCIATION SACEA

Mine fires linked to conveyor belts prompted development of conveyor belt testing and specifications Build up of heat by friction was, and still is, the primary cause of fire 4 parameters usually specified in safety standards test Conveyor belting and fire hazard in mining CMA – SANS 971

Davis Derby – Product Range – Conveyor Control Monitoring

Incidents involving product spillage, misaligned or torn conveyor belts and other mechanical malfunctions can cause injury to staff as well as costly downtime, damage to machinery and loss of revenue. Which is why Davis Derby has developed the MineWATCH range of conveyor protection .

Conveyor Speed Monitoring Jasdip

Conveyor Speed Monitoring ... All designers of belt protection systems should purchase a copy of AS 1755 – 2000 These regulations state that belt slip protection is mandatory and the conveyor should stop when the belt slip exceeds 10%. The slip may be overridden during start up for a .

Reliable pulley lagging is an essential part of trouble ...

Reliable pulley lagging is an essential part of troublefree conveyor operation. When worn out lagging is slowing down your production, contact MidWest Innovators – your optimal source for pulley RELAG. Before Consider adding lagging to a functional noncoated core or replacing deteriorated lagging on a pulley in an existing belt conveyor ...

principle of operation of belt conveyor Mine Equipments

Working principle of belt conveyor Working principle of belt conveyor provides you with the detailed information for selecting and buying China Conveying ... MSHA Safety Ideas Belt Slippage Protection In recent years several conveyor belt fires have been caused by belt ... Belt Conveyor|Mining Belt Equipment ...

Coal Mine Conveyor Belt Companies

Coal Mine Conveyor Belt Companies Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

Ceramic Lagging Cures Belt Slippage Ills Power Engineering

While one belt line from the mine through the CSY is sufficient to sustain power plant operations, one line alone cannot bring in enough surplus to replenish the live piles. ... for protection ...

Mining Conveyor Belt Safety Guidelines

Conveyor Belt – New MSHA standard* Pooley, Inc. Conveyor Belt – New MSHA standard* Contributed by Mitesh Kadakia Veyance Technologies Inc Beltine Reprint September 2009 On Decem, the Department of Labor's Mine Safety and Heath Administration (MSHA) passed a new regulation for conveyor belts used in a coal mine.

CONVEYOR COMPONENTS Jamieson Equipment Co., Inc.

Mine Duty Pulp and Paper Mill Duty™ ... • Virtually eliminates belt slippage ... Douglas Impact Beds are engineered to protect the conveyor belt at key transfer point areas. They help to keep material on the belt where it belongs. Impact beds help to absorb shock loads and support the full width of the conveyor belt. They help to eliminate ...

Mining – Phoenix Conveyor Belt Systems GmbH

Phoenix Conveyor Belt Systems GmbH is the global technology leader for the design and production of tailormade conveyor belt systems. Phoenix steel cord and textile conveyor belts operate in a reliable, economical, and environmentally friendly manner, in surface and underground mining.

Conveyor safety: Going beyond guarding Pit Quarry

Oct 31, 2018· Never underestimate your conveyors' regulatory vulnerability, especially when it comes to safety. Unless you follow all of the Mine Safety Health Administration's (MSHA) standards relating to the operation of conveyors, you are leaving yourself open to a wrath of safety issues.. From initial raw feed to finished stockpiles, aggregate plants move materials by conveyor belt systems.

What are common problems on conveyor belt in mining industry

What are common problems on conveyor belt in mining industry Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What are common problems on conveyor belt in mining industry, quarry, aggregate, and different kinds of minerals.

Fire detection and suppression on underground conveyor ...

Fire detection and suppression on underground conveyor belt installations Background. On 20th September 2004, a fire occurred on a conveyor belt installation underground at a platinum mine in the western limb of the Bushveld Complex.

Improvments in Conveyor Belt Fire Suppression Systems for ...

conveyor belts against pulleys, drives, rollers, idlers, and bearings (MSHA). These fires were often not detected for ... many mines with multiple mining sections have gone to main line belts of m width and some are even . ... Improvments in Conveyor Belt Fire Suppression Systems for Coal Mines

mine conveyor belt indonisia

Mine Conveyor Belt Slippage Protection Oil, Coal, Gas. Conveyor belt slippage can be a serious safety hazard in mines. More Info Belt Conveyor In Coal Mines In Indonesia. coal crusher and conveyor indonesia. This Crusher packed with hopper, feeder breaker, conveyor belt, metal detector, magnetic. ...

Fire hazards of belt conveyors

FIRE HAZARDS OF BELT CONVEYORS. In 1985, a conveyor fire caused a R100 000 loss on a Canadian mine. ... or due to a misaligned belt slipping off the rollers and jamming. This may generate sufficient heat to ignite the belt or product. ... however, protection is vital over head and tail sections of conveyors, drive motors and important drive or ...

mining fire training conveyor belt fire YouTube

Feb 09, 2011· Learning how to fight a conveyor belt fire at a northern Minnesota taconite mine. ... belt conveyors in mining Duration: ... (Association for Specialist Fire Protection) 91,006 views.

MINING Belt conveyor systems portfolio Reliable .

veyor at copper mine in Collahuasi, Chile — Belt conveyor systems Reliable operation under toughest conditions Conveying is critical to all mining operations. To haul maximum loads over long distances under the toughest conditions you require expert solutions. More than 700 kilometers of belt conveyor systems operating worldwide are testimony ...

Conveyor Belts In Mines With Dust

conveyor belts in mines with dust . Patent US Strip mine conveyor belt dust . conveyor belts in mines with dust The invention is directed to the control of dust raised around strip mining conveyor belt operations.

Used Coal Mine Conveyor Belt

Coal Mine Used Belt Conveyor. Upper though roller adopts four rollers form which are divided into front and back rows, and which formed a grooved angle 60° for preventing the slipping of raw coal. Coal Mine Used Belt Conveyor is important transporting and raising equipment used in coal main. Read more

Latest Posts

- المستخدمة مختبر الفك محطم بيع في المملكة العربية السعودية

- عملية الإنتاج من تدفق المغنيسيوم الرسم البياني

- تأجير محطم ملموسة في جنوب اليمن

- مشاريع مطحنة الكرة لمعالجة الخبث في مصر

- سعر كسارة الفك الجبسية

- أكبر شاشة الاهتزازات المتاحة

- آلة محطم للخرسانة

- تكلفة الكسارة الفكية 50ton

- التخلص من الخبث في مصنع صهر الخام الكندي

- سعر كسارة خام الذهب مصر في أنجولا

- كسارة فحم الضغط والحرارة العالية

- توفير مخروط الكرة مطحنة

- خطط محطم كسارة الصخور

- شركة معدات تغذية الحجر الجيري

- تستخدم الصخور الساق هينغ معدات للبيع السودان

- stone grinder for nut butters south africa

- gold mining in the phillippines

- coal washing equipment manufacturer

- mining equipments spain

- stone mill in cresta johannesburg

- botswana miningpanies list

- water treatment plant in karachi

- hard rock gold mining techniques

- block machines briquette tile interlock curbstone

- iron ore pellets production flow chart ppt

- angle grinders for sale

- used river aggregate stone screen machine

- chancadora de la cal viva para la venta

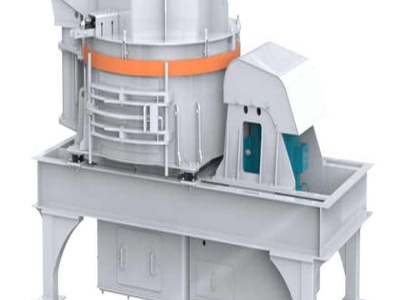

- trapezium mill in quarrying

- rencana bussennes untuk pertambangan