minerals grinding

Minerals Engineering International Online mineral ...

May 17, 2019· Minerals Engineering International Online: The largest source of information on mineral processing and extractive metallurgy. Including froth flotation, comminution, hydrometallurgy, pyrometallurgy, solidliquid separation, sizing and classification, applied mineralogy, electrometallurgy, bioremediation, gravity concentration, magnetic separation, grinding, solvent extraction and much more.

Charah Acquires SCB International's Ash Beneficiation and ...

May 01, 2018· LOUISVILLE, KY (May 1, 2018) – Charah®, LLC, a leading provider of ash management, fly ash sales and marketing, and utility support services for the coalfired power generation industry, today announced that it has acquired SCB International, Inc. (SCB) to jointly develop and deploy innovative technologies, including fly ash beneficiation and mineral grinding technologies for:

Slurry rheology in wet ultrafine grinding of industrial ...

Oct 11, 2004· From the viewpoint of slurry rheology, the role of chemical dispersants or grinding aids is primarily to minimize or to completely eliminate the yield stress of a ground slurry [36]. In general, interparticle forces in an aqueous suspension of minerals consist of a van der Waals force and an electrostatic force.

Introduction to Mineral Processing Chevron Phillips Chemical

This fine grinding separates the individual mineral particles from the waste rock and other mineral particles. The grinding is normally done in water with the resultant slurry called the pulp. The pulp is processed in the flotation cells, which agitate the mixture and introduce air as small bubbles.

SJ Enterprises (Mines Minerals Grinding Industries)

SJ Enterprises (Mines Minerals Grinding Industries) established in 2005 and is one the leading metallic nonmetallic minerals ore fine minerals supplier. We can supply export various qualities of minerals fine ore to our valued customers with maintain quality and standard.

JAMIPOL

Mineral Grinding Conversion of steel plants reject Lime into micron sized powder lime for use in sinter making JAMIPOL sets up and operate lime grinding plants inside customers premises to convert the reject lime fines (10 mm or 25 mm) of steel melting shops to fine lime powder (75 microns) and deliver the same to sinter plant for producing ...

Grinding : BASF SE Mining Solutions

May 07, 2018· Grinding. Along with other important slurry properties that affect the grinding of mineral slurries, such as solids concentration, particle size and temperature, the use of dispersants in grinding has a significant influence on slurry rheology. Therefore, rheology is a useful variable to be controlled in industrial processes such as wet grinding.

DARAGRIND Mineral Grinding Aid

DARAGRIND Mineral Grinding Aid Mineral Grinding Aid Product Description DARAGRIND is one of the largest product developments by GCP Applied Technologies in the field of Grinding Additives for minerals, cement raw materials, coal, pure calcium carbonate, .

Kinetics of dry grinding of industrial minerals: calcite ...

Kinetics of dry grinding of industrial minerals: calcite and barite E. Teke, M. Yekeler*, U. Ulusoy, M. Canbazoglu Department of Mining Engineering, Faculty of ...

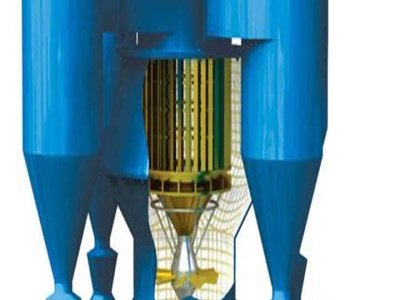

Swiss Tower Mills Minerals AG

Swiss Tower Mills Minerals AG develops fine and ultrafine grinding mill products, using an innovative technology. A range of services is available from consulting, conceptual and detail engineering to production, site assembly and lifecycle service support.

minerals grinding 2006

Minerals Grinding Corporation has been the pioneer in mining and processing of Bentonite in India since last three decades. We are one of the leading mine owner, processor and exporter of Bentonite in India. Live Chat. Mineral hardness effect on the combined mineral .

Crushing Grinding – The Anchor House, Inc.

Sep 09, 2016· Crushing Grinding Sep 9, 2016 | The purpose of crushing and grinding is to reduce the size of the potential ore particles to that where there is sufficient REE mineral liberation and the size/size distribution is suitable for the chosen downstream mineral recovery process.

ball mill in mineral grinding mills

A Grinding Ball Mill is a type of grinder used to grind and blend materials for use in mineral processes A Grinding Ball mill works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell.

Prince Minerals plans a future in Houston after buying ...

Jul 18, 2013· Minerals company plans a future in Houston. Grinding and Sizing produces, blends and sizes different materials that go into drilling fluids, and it has two Lufkin plants as well as one Houstonarea plant. Densimix has a single Houston plant, and it processes and markets iron oxide products for multiple industries,...

Enduron HPGR High Pressure Grinding Roll First choice

High Pressure grinding has become the "go to" technology for size reduction in mineral applications with more than 200 High Pressure Grinding Roll (HPGR) installations across the world. Most new greenfield projects include HPGRs as part of their standard comminution flow sheet.

Toll Processing, Milling and Grinding Prater

Toll Processing Overview; Prater's toll processing services have helped customers to testmarket a new product prior to investing in new processing equipment. We maintain fullsize production equipment in our Toll Lab so that large quantities for market testing, emergency production or product development can be processed for our customers.

Latest Posts

- عملية صنع الرمل الاصطناعي في كويمباتور

- كسارات حجم المختبر لخام الحديد

- كسارة الفحم منخفضة السرعة

- ggbs المصنعين كسارة

- سحق آلات مصر

- المعدات يحتاج لصناعة الاسمنت

- كسارة مخروطية 2 قدم cs

- خط تجهيز الماس المورد

- اقتران لمعدات كسارة

- خام الحديد من الجزائر

- كسارة الفحم محطات توليد الطاقة الحرارية

- وظائف شاغرة البكالوريوس بكالوريوس التعدين الصناعي

- مخروط المغنيسيوم لكسارة الصخور

- كسارة الحجر في mubarakpur

- صخرة كسارة مصر الصانع

- 200tph stage stone crusher machine manufacturer in india

- how do they mine iron ore

- industrial grinders available in south africa

- portable crushing machine for limestone crushing

- wedge rolling mill untuk bola bergulir

- quarry of white cement

- conveyor belt ppt presentation download

- what are the component of nigeria running industry

- crusher gyratory sizing power

- mobile crusher jermanmobile crusher jg

- kaolin screening equipment price

- stainless steel rolling mills malaysia

- china manufacturing cone crusher

- hyundai mining equipment for sale

- quarry equipment for sale australia