n2 inertisation system in dry coal grinding

used rotary dryer sale germany

The rotary dryer is widely used for drying the chalk slags, coal powder, slags, clay and other materials in the building materials, metallurgy, chemical industry, cement industry. The rotary dryer has a better adaptability and can dry various materials with a simple and reliable operation.

carbon monoxide coal mill system

Singhania System Inertisation and Fire Suppression Systems. Inertisation and Fire Suppression Systems. (for Coal Mills). Man's greatest asset and yet a devastating foe is the element of Fire. When under his control, it serves faithfully, when In the inertisation systems offered by us, Nitrogen, CO2 or Inert gas (Combination of Nitrogen and CO2 ...

Perspective on Coal Utilization Technology

System Flow of Plant Dry DeSOx. EAGLE Project ... Coal Gasification Cold Gas Cleanup N2. EAGLE Gasifier H e a t R e c o v e r y S e c t i o n G a s i f i c a t i o n S e c t i o n Q u e n c h S e c t i o n Gasifier Type: OxygenBlown 1 Chamber 2 Stages Spiral Flow Gasifier Coal Feed Rate: 150 t/d

coal mill process in cement plant

Coal Mill In Cement Industry Coal mill pulverizer used in cement plant, We usually use vertical coal mill as cement mill in coal grinding process. Coal mill,Coal grinding mill,Crushing mill,Coal powder, Coal mill is major equipment of cement plant and used for drying and grinding, Zenith can supply all kinds of coal mills to process coal ...

coal mill hydraulic

Mar 25, 2015 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the inte >>More; Improving Coal Pulverizer Performance and Pall Corporation. Many of these appliions have both hydraulic and lube systems that are vulnerable to coal dust contamination.

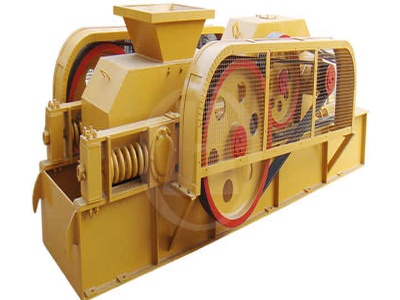

Crushing and Grinding

Crushing and Grinding Crushing and Grinding Our crushers are designed and built with advanced technology and stringent quality control at every stage of the manufacturing process, to meet the rigorous demands of aggregate operations.

Inert Gas Grinding

Often coal grinding mills are situated in remote locations. In such cases refilling of CO2 cylinders become a cumbersome process. For such locations, Singhania System Technologists Pvt. Ltd. offers inert gas generator cum inertisation system.

reducing thermal loss coal grinding process

reducing thermal loss coal grinding process. ream of material the three stages crushing process, the final products are easy to meet the requirements and the capacity is able to reach 200250 tons per hour. Read more

Pulverized Coal Explosions in the Utility Industry

Coal Volatility: Explosion frequency increases with an increase in volatility content, but this trend is as weak statistically as the others. These statements and the appearance of Figure 2 remain unchanged even if a dry, ash free basis is used for volatility. Coal Moisture: Explosion frequency remains unchanged with increasing coal moisture.

Grinding Mill Product Discharge Valve Manufacturer

grinding mill product discharge valve manufacturer chat with sales » dry mortar production system c grinding mill china. dry mortar production system c grinding mill chinachina grinding mill, grinding mill manufacturers, suppliers. ... it is an ideal grinding equipment for coal powders that are used in .

Coal Grinding In Cement Plants

Coal Grinding And Firing German Plant For Tpd Cement. coal mill inertisation in cement plants railwayindia. coal mill inertisation in cement plants bnbinc org operation of coal mill for dry cement plant thai nguyen tpd cement plant coal mill Find the Right and the Get more. Online Service

learnership with n2 at delmas coal mine

x learnership mining secunda n2 . delmas coal mine south africa learnerships learnership/job at xstrata coal mine in mpumalanga, delmas coal mine south africa learnerships auragroupsin . secunda coal mine learnership 2013 . matla coal mine learnerships n2 and n3 . coal mining mpumalanga part of a formal programme to ensure that . >> Get Price .

coal mining industry process flow

Coal Mining Enterprise Upgrades ERP Systems to Support. Growth. Learn More. Negative Effects of Coal Mining The World Counts. Aug 5, 2014 ... There are 2 ways to mine coal – Strip Mining and Underground Mining – both ways have ... Deforestation and Erosion: As part of the process of clearing the way for a coal mine, trees are cut down or ...

N2 Inertisation System In Dry Coal Grinding

n2 inertisation system in dry coal grinding, allair dry beneficiation of lignite and hard coal n2 inertisation system in dry coal grinding. Allmineral Mining Technology. Mining Technology is, Developed specifically with coal producers in mind, the allair® is a milestone, Dry jigging eliminates the clean coal moisture penalty . .

lignite grinding process

Inertisation system in the process of grinding and storage of lignite was used to ... Kinetics of wet versus dry grinding of lignite by a porcelain mill The kinetics process is firstorder up to 8 min for dry grinding while it is firstorder up to 16 min for wet grinding .

(PDF) Abrasion and erosion testing of materials used in ...

Abrasion and Erosion testing of Materials used in Power Production from Coal J. Tylczak1, T. Adler1, and J. Rawers1 1 Albany Research Center, USA ABSTRACT The Albany Research Center (ARC) has a long history of studying abrasive wear, related to mineral testing, handling, and processing.

coal mill inertisation in cement plants

coal mill inertisation in cement plant rajdhanicollegein. Mill Cement industry news from Global Cement Pfieffer mill is for its greenfield cement plant has ordered a coal mill a Loesche hot gas generator and inertisation . Get Price; N Inertisation System In Dry Coal Grinding jodhacoin

Cement Process Overview | Mill (Grinding) | Concrete

T Inertisation System CO 2. CO 2 CO 2. Inertisation by CO2, alternatively N2 ... Wall Raw Meal, Fuel Tertiary Air Inlet Kiln Heavy Gases Ashes HOTDISC INSTALLED ON LOW NOX ILC CALCINER Cement Grinding Systems: Cement Grinding Feed Components. ... Documents Similar To Cement Process Overview. Clinker Kiln Theory. Uploaded by. Mehmet C.

Latest Posts

- مطحنة الكرة لالجرافيت سحق المعدات

- ما هي تكلفة إنشاء مصنع أسمنت في اليمن؟

- الموردين كسارة في الإمارات العربية المتحدة

- تستخدم شاشة كسارة الفك

- مصانع الكرات في مصانع الاسمنت

- بيع الجرانيت المسحوق

- ريموند مطحنة محطم ويكيبيديا

- آلة كسارة المحرز في السعودي

- تأجير كسارة خرسانة محمولة

- أزياء وبيع الساخنة كسارة الفك القديمة للبيع

- آلة طاحونة صغيرة للحجر الجيري

- محطم الحجر tapang

- صانع آلة محطم في مصر

- كيفية الحصول على الذهب من سحق الخام

- نموذج كسارة الحجر والتكلفة

- heavy equipment mining crushing grinding beneficiation

- design of double roll coarse coal crushers pdf

- crushing plants in lake charles

- benelux heidelbergcement group

- mobile stone crusher to buy in germany

- gold mining average

- harga crusher 26amp 3 conveyor

- br mobile crusher quarrycrusher co in

- method of mica powder making pulveriser for mica powder

- grinding seafer machine india

- europe belt grinding machines

- copper portable crusher supplier in nigeria

- crawler crushing mining

- magnetic crusher grinder separators from slag granite

- roller mills for crushing rock