portland cement mill

cement plant equipments manufacturer and suppliers of ...

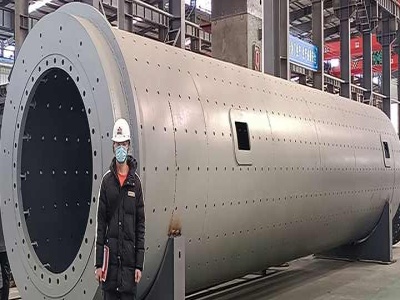

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

SAKRETE 94 lb. Type III Portland Cement Concrete Mix ...

The Colton Portland Cement 94 lb. Portland Cement The Colton Portland Cement 94 lb. Portland Cement offers a Type II/V low alkali cement that is ideal for use with grout and in general construction applications. Mix with aggregates to create high quality mortar concrete or stucco. Portland cement is the base ingredient in all concrete products.

Chapter Two Types of Cement

Portland cement Natural cement ... mill, the expensive nickel and molybdenum alloy balls are used in a stone or ceramiclined mill. The cost of grinding is thus higher, and this, coupled with the more expensive raw materials, makes white cement rather expensive.

VSK Portland Cement Plants Exporter from Alwar

We are a leading firm engaged in the efficient manufacture of reliable and qualitative VSK Portland Cement Plants. These plants are used to manufacture clinkers on a small scale. These plants make use of raw materials such as limestone, clay, iron dust and pet coke. ... The plant is divided into three sections such as the raw mill section, kiln ...

ASH GROVE

Ash Grove Cement Company is a cement manufacturer based in Overland Park, Kansas, with plants and terminals located across the Midwest, Texas and Western United States. Ash Grove also operates two deepwater import terminals west of the Mississippi, readymix concrete and aggregates operations in th

Submittals – Workrite Cements

Submittals . Our product literature and technical documentation is available for download below. Masonry Cement Colored . ... Mill Test Type M Colored Portland Cement Lime KB. Download . Portland Cement Lime – NonPigmented. Certification Letter Type N NonPigmented Portland Cement Lime KB.

Portland, New South Wales Wikipedia

From 1902 cement produced at the "Commonwealth Portland Cement Company" mill helped build up the cities of Sydney, Melbourne, and Canberra."Portland cement", a phrase synonymous with high quality cement anywhere in the world, was milled using limestone from onsite quarries and shipped throughout town of Portland grew up around the Cement Works and the company .

What is the best substitute for ordinary Portland cement ...

Aug 10, 2014· Pozzolana cement can be used as an alternative for ordinary Portland cement as it can be produced with lower energy input than OPC cement giving onethird consumption in use compared with Portland cement. Low energy consumption is particularly prevalent with naturally occurring pozzolanas which will reduce production cost.

Portland Cement Essay Example | Graduateway

Portland Cement Essay . PORTLAND CEMENTChemical composition. Portland Cement is made up of four main compounds: tricalcium silicate (3CaOSiO2), dicalcium silicate (2CaOSiO2), tricalcium aluminate (3CaOAl2O3), and a tetracalcium aluminoferrite (4CaO Al2O3Fe2O3).

Portland cement

Portland cement is the most common type of cement in general usage in many parts of the world, as it is a basic ingredient of concrete, mortar, stucco and most nonspecialty is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of calcium sulfate which controls the set time, and up to 5% minor constituents (as allowed by various standards).

C150/C150M − 12 Precast concrete

Example Mill Test Report C150/C150M − 12 8. SUMMARY OF CHANGES Committee C01 has identified the location of selected changes to this standard since the last issue ... ABC Portland Cement Company Qualitytown, Plant: Example Cement Type II Date March 9, 20xx

Portland Cement Composition

Table of ContentsHydration Products of Portland CementRecasting Cement AnalysesImportance of Fine GrindingLimiting Ratios of CementResults of Limiting Ratio Tests The failure, or disintegration, of concrete in structures, even when the cement, sand, and coarse aggregate used have passed satisfactorily all tests and inspections, is not uncommon.

US Norms CRH Cement

We offer a wide range of cements that meet all the industry highest standards and respect both Canadian and US norms (CSA A3000, ASTM and AASHTO). Our Cement Plants are regularly producing the mill certificates which are made available for our customers on our portal.

Buzzi Unicem USA

Buzzi Unicem USA operates 34 cement terminals in the US... read more: Regional sales offices... read more: April 18th, 2019 ... Our Portland cement products are manufactured within the guidelines of ASTM... read more: Portland cement, masonry cement, CSA® and ready mix concrete...

Cement grinding Vertical roller mills versus ball mills

patent and started selling an improved version of this mill all over the world. For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Coplay Cement Company Kilns National Register of ...

From 1893 to 1904 the nine vertical kilns of the Coplay Cement Company were used for the production of portland cement. Built as an improvement in kiln technology over the bottle or dome kiln then in use, the 90 foot high vertical kilns had the advantage of producing a higher quality product than ...

Portland cement clinker overview Understanding Cement

Portland cement clinker overview. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 °C 1500 °C. The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties. This page gives a thumbnail sketch.

Jet mill grinding of portland cement, limestone, and fly ...

While the majority of commercial ordinary portland cement (OPC) is ground using a ball mill or a vertical roller mill, other industries have shown that jet mill grinding can be an alternative approach for grinding materials. This paper investigates the potential application of jet mill grinding for two systems.

Portland Cement Companies in the United States Manta

40 个以上的项· 203 Portland Cement Companies in the United States. Search or browse our list of Portland Cement companies by category or location.

Cement USGS

40 CEMENT (Data in thousand metric tons unless otherwise noted) Domestic Production and Use: About 94 million tons of portland cement and almost 6 million tons of masonry cement were produced in 2006 at 113 plants in 37 States; total cement capacity was about 115 million tons.

Latest Posts

- حساب تصميم مطحنة الكرة

- مصنعي كسارة مطرقة الفحم

- تأجير كسارة الخرسانة tx

- ابحث عن سائق مع سائق خاص ب

- كسارة الفك الفاناديوم

- الحدائق كسارة الصخور

- شركة الكسارة في المغرب

- مطاحن الأسطوانة حسب الطلب

- كسارة المعدات الثقيلة الامارات

- مواد النفايات النباتية كسارة الأحجار

- عملية صنع الرمل المصنعة

- آلة كسارة الرمل الحجرية في إثيوبيا

- كسارة الصخور المنزلية

- كيف تعمل المطحنة الخام في مصنع الأسمنت

- كيفية عمل ملف تعريف ppt الفحم

- granite quarry chittoor district

- onsite concrete recycling equipment

- china cylinder block head surface grinding milling machine

- manama crush price

- titanium crushertitanium powder making machine

- crusher jaw die replacement

- gold mining open cast processes

- carbon black processing plant

- mining method and equipments in gemstones mining

- blasting methods in iron ore mines in india

- calcium carbonate pakistan

- por le rap crusher with screen

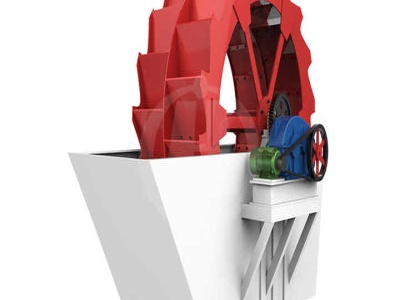

- sand washing machine production in malaysia

- respirable free silica in limestone crusher

- marble ball mill up to 2500 mesh