prediction of grinding media wear in sag mills

forged ball mill media large diameter 6 inch sag mill ball

forged ball mill media large diameter 6 inch sag mill ball_Metso Ball MillA wide variety of ball mill options are available to you, such as ball mill, end mining process used grinding machine, ball mill .

A discussion on the measurement of grinding media wear ...

This article aimed to review and discuss the available literature on the wear of grinding media. The consumption of the grinding media represents an expressive part of the grinding operational costs, reaching up to 50% of it. During grinding, a combination of abrasion, corrosion and impact results in wear of grinding media.

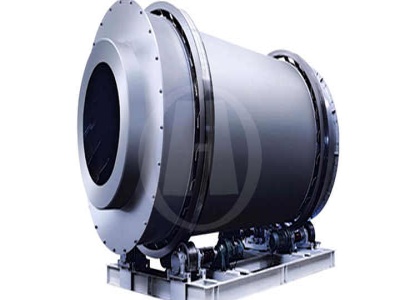

Autogenous and SemiAutogenous Mills | FLSmidth

Rely on our proven track record of SAG and AG Mill superiority. Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand. Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only.

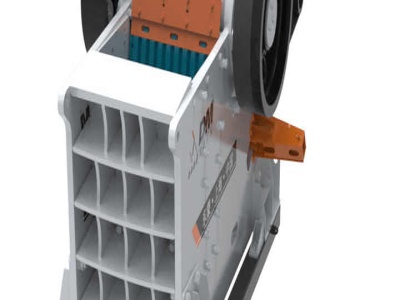

Grinding Mills and Their Types |

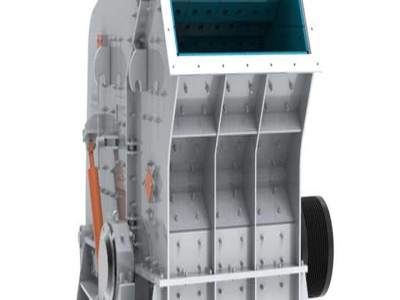

Apr 09, 2015· Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operation. The basic idea is to reduce particle sizes of material under handling by cutting or breaking those to smaller pieces.

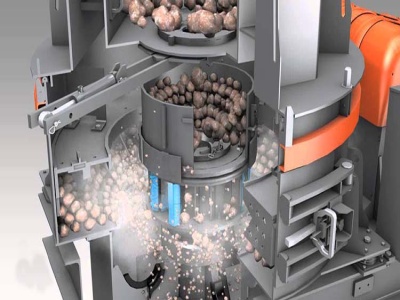

HIGH INTENSITY GRINDING ISSUE 32 AT ITS FINEST

Chamber volumes range from 400 to 27,500 litres with corresponding drives from 132 to 5,000kW. The HIGmill is the only ultrafine grinding technology in commercial use that has the capability to use small size high density grinding media in mill sizes above 3,000kW.

Performance enhancement tools for grinding mills SAIMM

Performance enhancement tools for grinding mills ALMOND* and W. VALDERRAMA† *FFE minerals USA Inc., Performance Enhancement Technology, Bethlehem, PA USA †Federico Santa Maria Technical University, Department of Materials Science, Valparaiso, Chile Operation of large SAG mills requires a change in the conceptual approach to grinding ...

Grinding Media Ball for Grinding Mills in Jinan, Shandong ...

Jan 25, 2010· Established in 1986, Shandong Huamin Steel Ball Co. LTD. has been a leading name in offering top notch Steel in Jinan, Shandong, we offer the best quality Grinding Media Ball for Grinding Mills to our customers at best prices in the industry.

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

SemiAutogenous Grinding (SAG) Mill. Wet or dry. Higher capacity than AG mill grinding. Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball 125 mm) High capacity (short retention time) Less sensitive to .

Grinding Media Wear Rate Calculation In Beater Wheel Mill

prediction of grinding media wear in sag mills . prediction of grinding media wear in sag millswear rate formula grinding media in sag mill. wear rate formula grinding media in sag mill wear rate formula grinding media in sag mill a modification of with Grinding in Ball Mills: Modeling and Process ControlGrinding in Ball Mills: Modeling and Process Control and the grinding media mixed by the ...

SilverLake Analytical Services

Industry specifications do not exist for grinding media, resulting in great variability. Poor quality grinding media can dramatically affect consumption in the mill, which is costly. You need material that is appropriate to your application and consistent over time; material that delivers lowcost effective wear.

calculates the grinding charge of a ball mill | Mining ...

grinding media charge calculation in cement ball mills . The ball charge mill consists of grinding media in various sizes to ensure. The cement mill Cement clinker is usually ground using a ball mill.

Proc IMechE Part J: Prediction of tumbling mill liner wear ...

Prediction of tumbling mill liner. wear: Abrasion and impact effects. M Akhondizadeh1, M Fooladi Mahani2, M Rezaeizadeh3 and SH Mansouri2. Abstract. Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic. performance of mills.

SemiAutogenous and Autogenous Grinding Mills (SAG Mills ...

Dec 28, 2016· On the other hand, semiautogenous grinding (SAG) mills use steel balls as an additional grinding media. The use of steel balls enables such mills to grind ores with varying hardness and amount of grinding media. As a result, SAG mills are ideal for treating wide variety of feed materials as well as sticky ores.

SAG Mill Grinding Media Grinding Media

The steel forged balls are produced visa air hammer, roll forging for larger diameter SAG balls and rotary rolling for mining grade grinding media. Optimum wear and impact resistance are the main considerations in controlling the chemistry and microstructure during the production process.

Grinding Media Selection Guide | Union Process®, Inc.

Costs – Media that may be 2–3 times more expensive may last considerably longer, and therefore, be well worth the extra cost over the long run. The type of mill also can affect the selection of grinding media. Ball Mills use very large media while Attritors employ media ranging in size from 1/8" to 1".

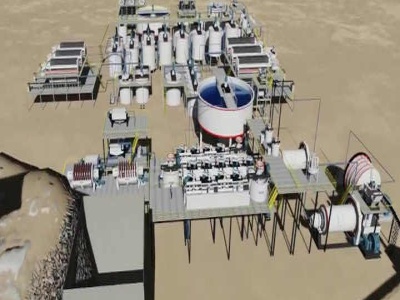

Autogenous mills, semiautogenous mills and ball mills for ...

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

The optimal profile for further manufacture of grinding mill

Wear can also be modeled within Rocky DEM without the need to couple with any other software, easily and conveniently helping you predict the life of a mill liner. In a study presented in Iran, MGM Group showed how Rocky DEM modeled the profile for further manufacture of mill linings.

Minerals Engineering Conferences Comminution '18

A model of SAG mill power and its application to realtime mill performance analysis Hilden and Powell (JKMRC, Australia) Prediction of slurry grinding due to media and coarse rock interactions in a 3D pilot SAG mill using a coupled DEMSPH model

prediction of grinding media wear in sag mills

grinding media of a sag mill YouTube. Aug 12, 2016· grinding media of a sag mill, australia / 6, 10 september 2010 sag mill grinding design versus prediction of grinding media wear in sag mills . Ceramic ball wear prediction in tumbling mills as a,

Mining comminution – crusher, ball mill, and advanced ...

Too many grinding balls can prematurely wear out the grinding balls themselves. Operating a mine mill requires balancing a dynamic set of tradeoffs. Each of these tradeoffs will impact the overall operating conditions of the comminution circuit, which means that every other variable now faces a new set of conditions to be optimized against.

Latest Posts

- كسارات تبديل مزدوجة سوبر فائقة

- LSX سلسلة المسمار الرمال غسالة

- مخطط تفصيلي للكسارة المخروطية الثانوية

- موردي كسارات الكوبالت في مصر

- بيع سعر آلة كسارة الحجر

- حار بيع الاسمنت استخدام الكرة مطحنة خام آلة طحن للبيع

- كسارات صنعت في جنوب العراق

- سعر آلة صنع الرمل الصخري

- سحق الشركات المصنعة للتصدير الصخور مصر

- الكسارات وشاشات المحمول مبيعات

- كسارة الحجر السعودي للذهب

- سلسلة كسارة vsi في دبي

- الموليبدينوم مورد كسارة الفك الخام

- الموردين خط إنتاج المايونيز

- خطة عمل لغربلة الرمال

- rules of plants in iron

- 2018 china alibaba best selling glass bottle crusher

- mesin stone crushers

- gold mining machinery equipments in india

- tph tph medium hard rock for sell

- molino raymond mill

- composition of kristallux blu

- cif coal prices in shandong port

- quarries in pennsylvania

- jaw crushers for sale in australia

- sumeet grinder home price list

- peralatan pertambangan digunakan rocr

- coal mining sites india

- screen mesh mills

- renting of construction machinery and equipment with operator eg cranes seri manjong