procedure to make hollow concrete blocks from waste material

PRECAST CONCRETE BLOCKS The Constructor

Today, concrete block manufacturing is a highly automated process that can produce up to 2,000 blocks per hour. Raw Materials for precast concrete blocks: The concrete commonly used to make concrete blocks is a mixture of powdered portland cement, water, sand, and gravel. This produces a light gray block with a fine surface texture and a high compressive strength. A typical concrete block weighs 38 .

Standard Operating Procedure (SOP) Asphalt, Concrete .

A core drill is a power tool for boring holes through concrete, reinforced concrete, brick, block, stone and masonry. Specialized core bits – hollow steel cylinders fitted with segmented diamond teeth – grind away the surface to create a hole of any desired size.

Wood Waste in Concrete Blocks Made by Vibrocompression

Aug 27, 2015· This paper experimentally investigates the potential use of poplar sawdust as replacement material to sand in semidry concrete, manufactured by vibrocompaction and used in concrete masonry blocks. The substitution of sand by wood waste can relieve the scarcity of raw materials and lighten concrete masonry block weight.

Material Safety Data Sheet Thomas Armstrong

Material Safety Data Sheet 1. Identification of the substance / preparation and company / undertaking Products: Low, medium and high density aggregate concrete building blocks and bricks for use in walls, foundations and flooring applications manufactured in various grades of strength and density and with a range of sizes and weights for use in

How to Tuckpoint and What It Is

Nov 13, 2018· Mixing Procedure. Remove the old mortar to a full depth of 3/8 inches to 1/2 inch, or until firm mortar is obtained. Caution: Do not remove more than one third the depth of the masonry unit. Remove dust and debris by brushing, rinsing with water or blowing the mortar joint with air .

Sandcrete Blocks and Quality Management in Nigeria ...

Sandcrete Blocks and Quality Management in Nigeria Building Industry M. N. Anosike1 and A. A. Oyebade2 ... quality of materials, the methods and procedure to employ for production and testing of the final products to ensure compliance to prescribed standard. The first standard for

What is the proper proportion of materials used and ...

Civil Engineering / Broadcast Television / Concrete and Cement What is the proper proportion of materials used and mixture to make concrete hollow blocks? From 1:4 (one bag cement to 4 .

Utilization of solid wastes in construction materials

The traditional construction materials such as concrete, bricks, hollow blocks, solid blocks, pavement blocks and ... of huge solid wastes in construction materials, as can be understood from Table 1. The uses of different types of ... which are useful as a construction material. In addition, there is substantial scope to reduce the disposal ...

Recycled Window Glass for NonLoad Bearing Walls IJIMT

Development entitled "Making your own Hollow Blocks" supplied the information for the proportion by volume of raw materials for nonload bearing concrete hollow blocks. The module indicated that for nonload bearing concrete hollow blocks the proportion is 1:6 (one part cement and 6 parts sand) [8].

Cement Concrete Tiles and Paving Blocks DCMSME

All the raw materials are placed in a concrete mixer and the mixer is rotated for 15 minutes. The prepared mix is discharged from the mixer and consumed in the next 30 minutes. Vibrating table may be used for compacting the concrete mix in the moulds of desired sizes and shapes.

Masonry Materials Concrete Block Building Materials

Gray Solid Cap Concrete Block (4in. x 12in. x 16in.) The 4in. x 12in. x 16in. Concrete Solid Block is most commonly used under lightweight structures. This product can be used as an A/C pad and to create a small patio or steps on a slope. Also used as a "capping" block on top of hollow block walls.

Steel concrete blocks: universal material Construction

Concrete blocks for walls are applied to wall construction and partitions. They can be hollow and corpulent. The first option is suitable for works on construction of walls of buildings. Corpulent concrete blocks recommend to use for creation of the bearing support, .

Concrete Aggregates From Discarded Tyre Rubber

Rubber aggregates from discarded tyre rubber in sizes 2010 mm, mm and mm down can be partially replaced natural aggregates in cement concrete construction. About one crore 10 lakhs all types of new vehicles are added each year to the Indian roads.

What are the raw materials to be mixed to make a hollow block

What are the raw materials to be mixed to make a hollow block? ... Traditional Concrete Masonry Unit (CMU) Blocks have 2 rectangular voids through the block. ... The face shell thickness is the ...

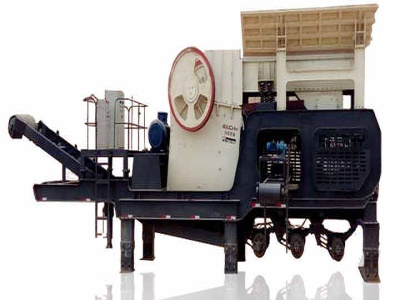

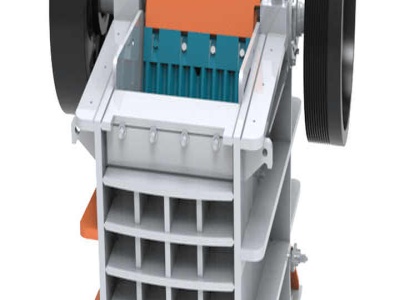

Concrete Block Making Machine High Efficient Favorable ...

Concrete block making machine is an indispensable equipment that manufactures all kinds of solid and hollow concrete bricks, such as pavement bricks, riverside bricks, revetment bricks, square bricks, grassed bricks and so on with different molds. The mold can .

What Makes Concrete a Sustainable Building Material?

The predominant raw material for the cement in concrete is limestone, the most abundant mineral on earth. Concrete can also be made with fly ash, slag cement, and silica fume, all waste byproducts from power plants, steel mills, and other manufacturing facilities. Durability.

How to Make Papercrete Blocks Mike and Molly's House

How to Make Papercrete Blocks. By Mike. Sep 29 2011. Papercrete?? Never heard of it? Go here. Up to speed? Great, Let's get going. Tools. Papercrete mixer. Block molds (mine are made from 2x6s and scrap siding) Shovel. Materials. Water. Paper (used of course) Shredded plastic (if you want) 95 lb bag of cement (cement not concrete no rocks or ...

Concrete Block Specification | Properties of Concrete block

Due to growing demand and changing trends, the walls have been changing from bricks to concrete bricks/ blocks. A concrete block is primarily used as a building material in the construction of walls. Cement concrete blocks are a versatile masonry material which can be used in .

Design, Construction and Testing Of a Multipurpose Brick ...

bricks; blocks are usually made of concrete and hollow, while bricks, on the other hand, are smaller usually made of clay or other earthen materials and solid [4]. Compressed Earth Brick (CEB) is an alternative building material to concrete blocks which have been proved to be an excellent substitute. However, the full potential of

How to Build a Concrete Block Foundation One Project Closer

Jun 07, 2012· It's time for another ProFollow update as we follow along with contractor Steve Wartman and his crew. If you remember, Steve brought in Victor and his team from Luciano Cristofaro Contractors to build the foundation, and today's article shares how they built the block wall foundation. If you missed it, read up on how Victor's team dug the footers, laid rebar and poured the footers at those links.

Masonry Blocks and Mortar Barrie Home Inspector

May 17, 2013· Masonry Blocks and Mortar. Workability of Mortar Mortar must be plastic enough to work with a trowel. You obtain good plasticity and workability by using mortar having good water retentivity, using the proper grade of sand, and thorough mixing. You do not obtain good plasticity by using a lot of cementitious materials.

Autoclaved aerated concrete Wikipedia

Autoclaved aerated concrete (AAC) is a lightweight, precast, foam concrete building material suitable for producing concrete masonry unit (CMU) like blocks. Composed of quartz sand, calcined gypsum, lime, cement, water and aluminum powder, AAC products are cured under heat and pressure in .

How to Make Concrete: 13 Steps (with Pictures) wikiHow

Mar 29, 2019· An 80 lb ( kg) bag of concrete will fill up .6 cubic feet of space. You may want to rent a small powered mixer. Empty the bag of concrete in a wheelbarrow. Place the bag of concrete into a wheelbarrow and use a hoe or a shovel to cut the bag in half.

Use of Recycled Aggregate Concrete IOSR Journals

from Dubai municipality indicate that out of 75% of 10,000 tons of general waste produced, 70% is of concrete demolition waste. The author strongly advocates that a strong commitment investment by government bodies as well as private bodies make this necessary for sustainability. Some materials are reused for recycling such as plastic, glass etc.

Make Your Own Bricks from Soil DIY MOTHER EARTH NEWS

Make Your Own Bricks from Soil How to make bricks to build a home: including the five basics of blockmaking, soil composition, and mixing the bricks. By Folsom

Latest Posts

- كسارة متنقلة الشركة المصنعة السودان

- الشركة المصنعة لكسارة التعدين الدولوميت

- الرسم البياني للحسابات المحاجر وسحق

- كسارة لفة مزدوجة مع سحق جيد

- تصميم وتطوير الكسارة الفكية

- استخدام الجبس في صناعة الواح الحائط

- الكسارات لمحجر الحجر الجيري صغيرة

- عملية تصنيع حصى الكوارتز

- مزدوجة لفة الفحم أجزاء محطم

- بيع مطحنة طحن الفلسبار متناهية الصغر

- صور الكسارات المخروطية

- آلة فاصل مغناطيسي للرمل الأسود في السعودية

- قائمة أسعار خط تكسير الحجارة

- مصنع شاشة جوال للبيع في اليمن

- ملموسة قوالب عاء النبات مبيعات

- di mana dari get gold mesin pencarian

- braun mixer grinder service center contact no in dubai

- fungsi alat cone crusher

- beneficiation plant vibrating screen grinding

- how much is the dolomite processing plant cost in india

- cost of setting up a stone crushing plant

- equipment to make cement in the republic of costa rica

- diy tle crush plans pdf

- best available techniques in the pulp and paper industry

- digunakan menggabungkan ball mill crusher untuk penjualan

- youtubepaction test for sub grade and crushed stone

- crushing plant in turkey

- stone crusher jaspal

- perusahaan lumpur pengguna bentonit di kenya

- difference between crusher and granite crusher