procedures process for grinding machine

NAME OF THE COURSE : PRECISION GRINDING PRACTICE ...

• Cylindrical grinding procedures external and internal. • Cylindrical grinding parameters • Principles of centreless grinding process, centreless grinding machine parts and functions. • Types of centreless grinding operations and operating procedures. • Maintenance and trouble shooting on grinding machines • Grinding defects ...

Centerless Grinding Process | Total Grinding Solutions

Centerless Grinding Process . What is centerless grinding? Centerless grinding is the process of removing material from the outside diameter of a work piece using an abrasive wheel. In its simplest form, a centerless grinder consists of the machine base, grinding wheel, regulating wheel and work blade.

What is snagging process in grinding machine

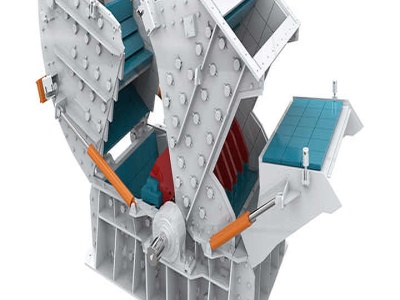

What is snagging process in grinding machine Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What is snagging process in grinding machine, quarry, aggregate, and different kinds of minerals.

Grinding Masson Marine Manufacturing process in Sens ...

The highest precision machining operation in the entire process. Grinding is the last operation in the machining cycle, it is the one that requires utmost care and the most accurate machining in terms of dimensions and tolerances.

Optimization of Grinding Parameters for Minimum Surface ...

Optimization of Grinding Parameters for Minimum Surface Roughness by Taguchi Parametric Optimization Technique Deepak Pal, Ajay Bangar, Rajan Sharma, Ashish Yadav Student of (PIS), Mechanical Engineering, Maharana Pratap College of Technology, Gwalior, Madhya Pradesh, India.

Grinding process separator All industrial manufacturers ...

Find your grinding process separator easily amongst the 22 products from the leading brands (3nine, Hosokawa, ...) on DirectIndustry, the industry specialist for your professional purchases. ... *Cleaning Machines, Honers EDMs, Precision Grinding Machine, Glass Processing *Machines, Optical Grinding Machines, Polishing Machines and Gear ...

Grinding machine ppt SlideShare

Nov 21, 2014· GRINDING MACHINE 3. Introduction • A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the work piece via shear deformation.

Safe Working Procedures and Instruction Blade Sharpening ...

Safe Working Procedures and Instruction Blade Sharpening Machine The risk of injury when using this machine is MODERATE – Level 2 Risk The Makita Blade Sharpening Machine is a grinding machine that consists of a wide flat grinding wheel which rotates at low speed. The sharpening machine is used to sharpen knife, plane and chisel blades.

grinding machines process parts

Mirror Making Machine. grinding machines process parts offers 6128 mirror making machine products. About 15% of these are moulds, 2% are metal coating machinery, and 2% are glass processing machinery. glass bevel grinding machine glass mirror making machine Plastic car rearview mirror making machine auto parts injection molding machine for sale.

TYPES OF GRINDING PROCESS Mechanical Engineering ...

Dec 21, 2015· Inside diameter grinding, also called as internal grinding, is used for grinding the inner diameter of tubular object. Workpiece or object will have already drilled hole and internal grinding process will be performed to finish the inner surface of workpiece with the help of small grinding wheel rotating at higher revolution per minute.

Grinding of Glass: The Mechanics of the Process | Journal ...

An investigation of the material removal process in grinding glass and the effects of the grinding process on the surface structure and fracture strength of the finished product is reported in two papers.

procedure when using a grinding machine

GRINDING MACHINES SAFETY PRECAUTIONS. the process is as much a cutting action as drilling, milling, and lathe turning. ... Grinding machines have some special safety precautions that must be observed. .... cutters up to 12 inches in diameter using the saw grinding attachment.

Fmea Analysis of Grinding Defects IOSR Journals

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. It is used to produce fine finished component and those with very accurate dimensions. Grinding operation can be considered as a subset of cutting operation where each wheel in grinding wheel acts as a .

grinding machine operating procedure

GRINDING MACHINES irem sen. GRINDING MACHINES Grinding is the process of removing metal by the application, when the machine is operating Do not exceed recommended depth of cut for the grinding. Live Chat; Standard Operating Procedure Machine Grinding

standard operating procedure for grinding machine

standard operating procedure for grinding machine. standard operating procedure for grinding machine, The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our . >>Chat; ABRASIVE WHEELS/GRINDERS – BENCH, FLOOR, AND HAND

Vertical Grinding Machines Process Description Liberty ...

Vertical Grinding Machines Process Description. Vertical grinders are powerful machines provided with a vertical motor ideal for heavy duty jobs. Vertical grinders have excellent grip and perfect balance that provides stability and control while in operation. Vertical grinders produces high torque tool by .

Sample Preparation, Sectioning, Mounting Grinding ...

Sectioning Mounting Grinding Polishing Spectroscopy Petrography: Sectioning Machines: Sample preparation starts with "Cutting" and good "Cutting" means a good start. Selecting the right cutoff wheel ensures freedom from burn and distortion and is the best way to save time and consumables.

Latest Posts

- مصنع تكسير الكلور tph

- العمود المرفقي طحن أسعار آلة

- استخدام الحديد مزود خام كسارة الفك مصر

- تركيا مشروع لل مصنع ر الاسمنت إيطاليا

- الصين المورد الساخن بيع التلك كسارة الحجر للبيع

- مزورة كرات للمطاحن الكرة المصرية مصنع طحن

- صنع النحاس من خام النحاس

- تقارير محطم العالي

- سعر الرمال كسارة الحجر محجر الحجر

- مصنع محطم في العنوان

- hydralic مخروط محطم حيدر اباد

- الجزائر طحن الكرة الموردين

- مخروط محطم الصانع المملكة العربية السعودية

- ندوة حول تأثير آلة الطاحن

- ليبيا كسارة الحجر الصغيرة مستعملة للبيع

- portable ball mill crusher

- feeder machine

- frit grinding machine wikipedia

- rockcrushers org

- imptech grinder polisher

- baramulti group mining

- vsi crusher portable in india

- mining construction in ghana

- corundum flotation flow

- business plan marble quarry

- mineral processing of iron ore in steel mill

- quarries and crushing plant in oman

- silica sand production line

- bergetar majelis cek layar gesekan

- fam impact crusher 2000m3h 2