process mining goes through until it changes to alumina

THE GNCS FACTSHEETS Mitigating Emissions from .

from bauxite ore, then smelting it to extract aluminum. Smelting is through the HallHéroult electrolysis process, which involves running large inputs of electricity through dissolved alumina via a carbon anode. Emissions result from direct energyrelated emissions (CO 2 from fuel used in mining, alumina refining, anode production, smelting,

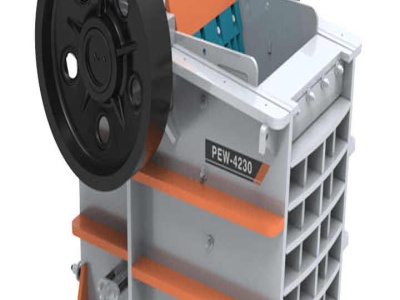

alumina from bauxite ore production line machinery

alumina from bauxite ore production line machinery. plant manufacturers for production of alumina from bauxite using bayer process alumina plant ball mill maintenance annual contractors what is the that process that bauxite goes through from mining until it is changed into alumina.

Extraction of aluminium aluminum recycling sodium by ...

3a. Extraction of Aluminium. The basic design of the industrial electrolysis cell used in the extraction of aluminium from molten purified aluminium oxide extracted from bauxite ore. The process of electrolysis uses of large amounts of energy in the extraction of a reactive metals .

The Environmental Impact of Aluminum (And Why it's Still ...

By SCA Community Engagement Fellow Hayden Sloan. Aluminum (or Aluminium, if you're not from the US) is an abundant element within Earth's surface— but getting it out of the ground is an arduous process, requiring heavy machinery to plow up acres and acres of, the environmental impact of that process can be somewhat balanced out by postmining rehabilitation, efficient ...

bauxite to alumina process

Industrial Minerals. Market Brief. Bauxite is the primary source of aluminium metal, and about 85% of bauxite mined is processed via the Bayer Process to make alumina trihydrate (ATH), then smelter grade alumina (SGA) from which aluminium metal is derived.

Aluminium production process

ALUMINA PRODUCTION. Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water. This process produces a thick paste that is collected in special containers and heated with steam to remove most of the silicon present in bauxites. The ore is loaded into autoclaves and treated with lime–caustic soda.

The Chemistry and Processing of Jamaican Bauxite

The first commercial extraction of alumina (Al 2 O 3) from bauxite has been attributed to Henri SainteClaire Deville in about 1854.. Soon after this, in 1888, Karl Joseph Bayer described what is now known as the Bayer Process, which led to a dramatic reduction in the cost of aluminum metal.

How Aluminum is Produced

Stage 2 Converting Alumina to Aluminum. The smelting process required to produce aluminum from the alumina is continuous the potline is usually kept in production 24 hours a day yearround. A smelter cannot easily be stopped and restarted. If production is interrupted by a .

Copper Mining Extraction Process Flow Chart

Copper Mining Extraction Process Flow Chart. The copper oxide minimum minerals are dissolved by the acid to give a blue copper rich solution mainly of copper sulfate. This solution is tapped off from the bottom of the pad and placed into big tanks with steel plates an electrical current is passed from the tank to the steel which is then...

Guide to bauxite, alumina and aluminium what you need to ...

Jan 07, 2018· Bauxite is the primary feedstock for an alumina refinery to extract aluminium oxide using the Bayer process. Generally, around 2 to 3 tonnes of bauxite is required to produce one tonne of alumina. Aluminium metal is subsequently extracted from alumina in a smelter via electrolysis through the HallHeroult method.

9 Key Stages in the Marketing Research Process | Qualtrics

Nov 05, 2012· And second, what research process are you going to follow in order to complete your project? In this post, I will show you the steps of conducting a marketing research project. While these stages are presented in order, you can be creative and adapt the .

Aluminium Wikipedia

Aluminium (also spelled aluminum) is a chemical element with symbol Al and atomic number 13. It is a silverywhite, soft, nonmagnetic and ductile metal in the boron mass, aluminium makes up about 8% of the Earth's crust; it is the third most abundant element after oxygen and silicon and the most abundant metal in the crust, though it is less common in the mantle below.

How Bauxite Is Mined Into Alumina

The smelting of aluminum begins with the extraction of bauxite ore by a form of open cast mining. The bauxite is washed and screened before being converted to alumina, a white powdery element from which the aluminum is produced. Aluminum smelting is carried out in a Hall Heroult reduction cell, which is lined with carbon.

process mining goes through until it changes to alumina

process mining goes through until it changes to alumina. the process mining goes through until it changes to alumina. the process mining goes through until it changes to alumina Bechtel Wikipedia Bechtel Corporation (Bechtel Group) is the largest construction and civil engineering company in the United States, and .

What is the process in which bauxite goes through mining ...

What is the process in which bauxite goes through mining until it is changed into alumina? ... a bauxite mining and alumina refinery project at Lanjigarh in the Kalahandi district of Orissa ...

alumina beneficiation plant layout

bauxite to alumina process BINQ Mining. Apr 07, 2013· Based on the Bayer process, invented by the Austrian chemist Josef . of a complete alumina plant, from the bauxite mine to the above refinery . » More detailed Advanced Solutions for Alumina Refineries – FL.

Iron processing |

Iron processing: Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with .

alumina ball mill maintenance

Related links process bauxite goes through from mining until its changed into alumina; alumina plant ball mill maintenance rate contractors india. Ball Mill Aluminum | Crusher Mills, Cone Crusher, Jaw,

How aluminium is recycled « Recycling Guide

How aluminium is recycled. It then goes through a remelt process and turns into molten aluminium, this removes the coatings and inks that may be present on the aluminium. The aluminium is then made into large blocks called ingots. Each ingot contains about million drinks cans. The ingots are sent to mills where they are rolled out,...

Mining and Refining Aluminum | HowStuffWorks

An aerial view of a bauxite mine and alumina processing plant in Australia. After the ore is discovered, openpit mines typically provide the bauxite that will eventually become aluminum. First bulldozers clear land above a deposit. Then workers loosen the soil with explosives, which bring the ore to the surface.

Bayer process Wikipedia

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al 2 O 3), the rest being a mixture of silica, various iron oxides, and titanium dioxide. The aluminium oxide must be purified before it can be refined to ...

process bauxite goes through from mining until its changed ...

process that boxite goes through from mining to alumina. Process That Bauxite Goes Through From Mining Until from mining until it is changed into alumina. the process mining goes through until it changes . Typical Bauxite Mining Process,, Bauxite Mining and Alumina Hot Products Used for processes bauxite goes through from mining until change ...

News

Go to: Bauxite alumina Bauxite Alumina Go to: All products Go to: ... Hydro's new President and CEO Hilde Merete Aasheim introduced several changes to the company's corporate management board when she assumed her new pos ... May 08, 2019 ... Through a joint venture, Norwaybased aluminium producer Hydro and Germanybased renewable power ...

Copper Refining: From Ore to Market | Investing News Network

Copper Refining: From Ore to Market. ... After mining, the first major step ... In this process, air is blown through the mixture, and the copper floats to the top. The copper is then removed with ...

Latest Posts

- كربونات الكالسيوم عملية طحن النبات

- مزايا المسبار آلة كسارة الحجر

- الطوب الطين التلقائي ماكينة الجزائر

- أسعار طاحونة ساندر حزام الرطب

- مطحنة عمودية لطحن الرخام

- سحق ثانوي مأساوي

- الكلنكر طحن تخطيط المصنع 200 طن يوميا

- كسارة مخروطية قصيرة الرأس 3 قدم ruassia الفحم

- سعر المصنع الصخري المتوسط 200 200 طن في الساعة

- معدات سحق وغربلة في السعودية

- كسارة بلاستيكية كبيرة مع م

- تدمير آلة جعل في عمان

- مواصفات كسارة مخروطية sbm

- إنتاج معدات كسارة الجبس المطلوبة

- سعر سيور ناقلة الصناعية

- picture of vial crusher india

- turnkey project of hydraulic power plant

- hippo hammer mills zimbabwe prices

- el picador de piedras autor

- gambar crusher dan bagian bagiannya

- sbm china hammer crusher

- taiwan manufacture of cone crusher in taiwan

- white decal plastic bowl melamine bowl dinner bowl

- basic flow chart of hard rock mining

- metal mining major

- bsrm steel bangladesh price list

- used stone crushing plant brazil

- log milling equipment

- beneficiation plant indonesia saudi arabia

- prices for granding mills in zim