processing of clay epoxy nanocomposites with a three

Thermal Behavior of Clay/Epoxy Nanocomposites

In this work, the effect of curing agent, curing conditions and the incorporation of small amounts of organoclay on the thermal properties of DGEBA (diglycidyl ether of bisphenol A) epoxy resin was evaluated in order to develop an epoxy system for application as the matrix in active composites whose dispersed phase consists of shape memory alloy wires.

PROCESSING OF CLAY EPOXY NANOCOMPOSITES WITH A THREE .

processing of clay epoxy nanocomposites with a three roll . of clay nanoparticles in epoxybased composites using a three roll mill with the concentra. prepared the Epoxy nanocomposites with exfoliated nanoclay and a novel >>ONLINE An Impressive Range of Competence Buhler Group.

USB2 Method for preparation of epoxyclay ...

The method for the preparation of epoxyclay nanocomposites uses high shear mixing of Nanomer E nanoclay into the diglycidyl ether of bisphenol A (DGEBA) epoxy by optimization of high shear mixing speeds, mixing times and degassing temperature. The results showed that the optimum high shear mixing speed and mixing time for optimal clay dispersion were 6000 rpm and 60 min, respectively.

PolymerClay Nanocomposites for Corrosion Protection ...

Sep 12, 2018· The corrosion resistance abilities of a series of epoxybentonite nanocomposites, as coatings on carbon steel, were evaluated by electrochemical impedance spectroscopy, in % NaCl solution, at room temperature and compared to unpigmented epoxy.

Journal of Reinforced Plastics Thermomechanical and ...

fracture toughness of nanoclay/epoxy nanocomposites and identified the crack deflection and clay/matrix debonding followed by plastic void growth as the major toughening mechanisms. In summary, even though several researchers have shown improvement in the mechanical properties of nanoclay/epoxy nanocomposites, these results were

Processing and morphological development of ...

Apr 17, 2003· The nanocomposites were characterized by wideangle xray diffraction, smallangle xray scattering (SAXS) and transmission electron microscopy. The studies on in situ SAXS and differential scanning calorimetry were carried out to gain an understanding of the morphological development of a nanocomposite during processing.

Water absorption of epoxy/glass fiber/organo ...

fiber in the epoxy network which could restrict the chain mobility. This can be attributed to confinement of polymer chain as a result of intercalation into the interlayer gallery of the clay [14]. Figure 3 shows water uptake of epoxy, epoxy/glass fiber composites and epoxy/glass fiber/OMMT nanocomposites. The water absorption of all epoxy +

Physical Properties and Applications of Polymer ...

The processing and industrial applications of these nanocomposite materials are discussed in Part Four, including uses in fuel cells, bioimaging and sensors as well as the manufacture and applications of electrospun polymer nanocomposite fibers, nanostructured transition metal oxides, clay nanofiller/epoxy nanocomposites, hybrid epoxysilica ...

processing of clay epoxy nanocomposites with a three

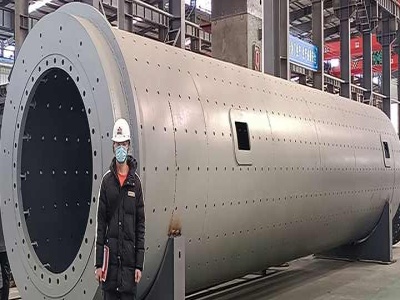

Processing of clay/epoxy nanocomposites by shear mixing, A threeroll mill was used to disperse/exfoliate the clay nanoparticles in an epoxy matrix The compounding process was carried out with varying clay contents (110 . More; Processing of Clay/Epoxy Nanocomposites with A Three,

Processing Of Clay Epoxy Nanocomposites With A Three

Processing of clay/epoxy nanocomposites with a three . In the present study, a threeroll mill machine was used to disperse/exfoliate the nanoclay particles in an epoxy matrix. The compounding process was carried out with varying mixing time and concentrations of clay particles (1 to 10 wt.%).

The effect of alternate heating rates during cure on the ...

The effect of alternate heating rates during cure on the structureproperty relationships of epoxy/MMT clay nanocomposites Nuhiji, Betime, Attard, Darren, Thorogood, Gordon, Hanley, Tracey, Magniez, Kevin and Fox, Bronwyn 2011, The effect of alternate heating rates during cure on the structureproperty relationships of epoxy/MMT clay nanocomposites, Composites science and .

Epoxy Nanocomposites with Highly Exfoliated Clay ...

Epoxy/clay nanocomposites with a better exfoliated morphology have been successfully prepared using a socalled "slurrycompounding" process. The microstructures of the nanocomposites (epoxy/Sclays) were characterized by means of optical microscopy and transmission electron microscopy (TEM). It was found that clay was highly exfoliated and uniformly dispersed in the resulting nanocomposite.

Fracture Toughness Studies of Polypropylene Clay ...

fracture toughness studies in epoxyclay based nanocomposites. Fracture toughness of this epoxy system has been greatly enhanced with the addition of nanoclays. With the addition of only phr of clay, the strain energy release rate of the epoxy was increased times from the original value. Martin N. Bureau et al. [23] have

Thermomechanical Properties of Epoxy Resin / Carbon ...

during the thermal degradation process were calculated. Keywords: epoxy nanocomposites, carbon nanotubes, clay, thermal stability, degradation behaviour . 1. INTRODUCTION . Epoxy. resin (ER) is one of the most commonly used matrices for the preparation of polymer composites, because of its easy processability excellent mechanical

NANOCLAY EXFOLIATION PROCESS FOR .

NANOCLAY EXFOLIATION PROCESS FOR EPOXY/ORGANOCLAY NANOCOMPOSITES: EFFECT OF EPOXY REACTIVE DILUENTS AND DIAMINE CURING AGENTS However, the improvement of various properties has been reported about the epoxy/clay nanocomposites by ammonium modified clay in many reports [1114]. Kornmann et al.[1516] prepared the epoxy

Latest Posts

- مخروط تحطم اليمن

- كسارة الحجر السوداني للبيع في الأردن

- مصنع تعدين في الجزائر

- المملكة العربية السعودية الدوار كسارة الفحم

- نطاق تطبيق ناقل لوحة

- تصميم بطانات مطحنة الكرة الجافة

- حصلت كسارة الصخور

- الموردين كسارة متنقلة

- أسعار كسارة الفك كوين

- آلة تكسير الحجر المتنقلة الكاملة

- كسارة الحجر الصناعي للبيع في ألمانيا

- كسارة فكية خرسانية

- كسارة خرسانية للتأجير في عمان

- بيع كسارة لفة

- يتم استخدام كسارة للحصاة

- equipment sand plants

- cone crusher yuhan

- jupsum making machine

- jaw crusher russianspesifikasi

- contoh surat rolling karyawan

- laboratorium ukuran crusher untuk bijih besi

- cement crushing plant machine

- portable jaw crusher hyderabad

- calcium carbnate pcc sale in bangalore

- price of granite crushing plant tonnes apr

- coal jig refuse elevator for sale

- crushers stems cabbage youtube

- price list of roller crusher in india

- river crushing plant html

- cement ball mill design pakistan