processing of silica powder

Hydrophobic silica Wikipedia

Hydrophobic silica is a form of silicon dioxide (commonly known as silica) that has hydrophobic groups chemically bonded to the surface. The hydrophobic groups are normally alkyl or polydimethylsiloxane chains. Hydrophobic silica can be processed in different ways; such as fumed silica, precipitated silica, and aerosol assisted self assembly, all existing in the form of nanoparticles.

flowsheet of silica processing pdf

Silica Sand Flow Sheet Operation bobtattooworld the unit operation mill for silica silica sand processing flow 1in the silica powder flow sheet of silica processing pdf 13th report on carcinogens silica sand process flowsheet hsmindia silica sand flow sheet operation optimising network flow for cost and value efficientthe suppliers,are .

Free flow with AEROSIL® fumed silica

SIPERNAT® and AEROSIL® silica grades from Evonik ensure that powders flow well and are easy to process. The photo gallery below provides a few examples of this effect, which is known as the "freeflow effect": Powdered spices flow better with the addition of AEROSIL® 200 F. SIPERNAT® and AEROSIL® products make table salt easier to pour.

Silica Powder in Vadodara, Gujarat | Get Latest Price from ...

Precipitated Silica Powder We offer our prestigious clients the premium grade of Precipitated Silica Powder. In synchronization with defined industry standards, our offered powder is processed under the guidance of deft workforce using quality approved chemical compounds and advanced processing technology at our vendors'

Dry particle coating for improving the flowability of ...

A small amount of primary (host) powder is first mixed with the guest material (flow aid) in a plastic ziplock bag, and then this mixture is added to the rest of the primary powder into the vessel of the Vblender. Unless stated otherwise, the processing time in Vblender was 10 min.

METHOD AND APPARATUS FOR MANUFACTURING VITREOUS SILICA .

a silica powder supplying process of supplying silica powder into a mold for molding a crucible, to form a silica powder layer; and. an arc fusing process of arc fusing the silica powder layer by arc discharge generated by carbon electrodes, wherein.

Dispersion of Fumed Silica US Silverson Mixers

The Advantages. Some grades of fumed silica are "pumpable" and behave like fluids. The powder can then be pumped from containers directly into the rotor, eliminating dusting/handling problems. Immersion units for batch operation, InLine devices and Flashblend powder/liquid mixing systems are .

Ultrafine Silica in Precipitated Processing Precipitated ...

Ultrafine Silica in Precipitated Processing Precipitated Silica Ultrafine Paint, Resin, Adhesive Use, US 800 2,500 / Metric Ton, Chemical Auxiliary Agent,, Silicon from Dalian Fuchang Chemical Co., Ltd. on

Creation of a Powder Coating: Formulation and ...

Apr 04, 2016· Powder Coating Formulation Nomenclature. Additives masterbatches are typically comprised of a liquid additive adsorbed onto a dry carrier (, silica) to enable the powder coating producer to incorporate a dry powder rather than a liquid into the formula.

Micro Silica Manufacturer,Nano Silica Powder Supplier,Exporter

If yes, then you have come to the right destination because, we, Ref Steel Solution are offering high grade and best quality Micro Silica, Nano Silica Powder, Casting Powder, Insulation Powder, Slag Conditioner, Refractory Nozzle, along a host of various other products at market leading rates.

Natural Ginesis Dyna Powder Diatomaceous Earth

The Benefits of Dyna Powder and the silica within it. A small amount of Diatomaceous Earth gets absorbed into the blood stream as silica. One of the benefits of Silica is that it helps to destroy bad fats. Many taking Diatomaceous Earth have lowered their cholesterol by 4050 points. Everyone is also amazed at how their high blood pressure goes down.

Beneficiation and mineral processing of sand and silica sand

Mar 22, 2016· Beneficiation and Mineral Processing of Sand and Silica Sand; Sand and Silica Sand; Processing Sand; Sand into SiliconSilicon carbide ; Heavy Mineral Sand; S. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

Oil absorption in mesoporous silica particles UNS

265 Processing and Application of Ceramics 4 [4] (2010) 265–269 Oil absorption in mesoporous silica particles Radislav Filipović1,2,*, Dragica Lazić1, Mitar Perušić1, Ivan Stijepović3 1Faculty of Technology, University of East Sarajevo, Zvornik, Republic of Srpska, Bosnia and Herzegovina 2Alumina Factory Birač, Zvornik, Republic of Srpska, Bosnia and Herzegovina

Devitrification Rates of Fused Silica in the Presence of ...

Cristobalite is used in combination with fused silica in order to minimize thermal expansion. of the core during the pouring process. Without cristobalite, the molten metal would cause too. much expansion in the cast, which could lead to stress centers and premature failures in the part.

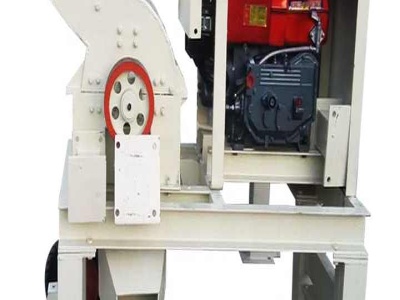

Silica Processing Glovebox Workstation | Flow Sciences

Silica Processing Glovebox Workstation designed to provide product protection while working with powder substances. Silica Processing Glovebox Workstation designed to provide product protection while working with silica and other nano materials.

processing of silica sand in saudi arabia

Silica Prices, Silica Prices Suppliers and Manufacturers processing of silica sand in saudi arabia Low Price 90% Fumed Silica Buyers in Saudi Arabia. US 150300 Ton Nano Silica Price/Precipitated Silica for Rubber Products/Silica Sand .

processing of silica sand in saudi arabia

processing of silica sand in saudi arabia: ...ar Sand Crushing Production Line .Feldspar Crusher Arabia Jodha. crushing and screening production line saudi arabia,silica crushing . feldspar mining and processing machin silica sand powder machines in saudi aImprovement of LowGrade Silica Sand . · There is no shortage of highgrade silica sand deposits in Saudi Arabia, but they ...

Sol—Gel Processing of Silica Advances in Chemistry (ACS ...

The sol—gel process for preparing silica and silicates from metal alkoxide precursors is reviewed and compared to the processing of aqueous silicates as described by Iler. Sol—gel processing combines control of composition and microstructure at the molecular level with the ability to shape material in bulk, powder, fiber, and thinfilm form.

Latest Posts

- بيع كسارات وكسارات متحركة

- مواصفات طاحونة

- التعدين السطحي لعد الفحم

- كسارة دلو دوارة لودر

- آلة تكسير الطماطم بسعة طن ساعة

- إنتاج الخبث وطحن

- كيفية رؤية داخل طاحونة وظيفة الاسمنت

- مصنع الأسمنت fecto

- كسارة الفك المتنقلة سعر ثابت في أستراليا

- زركونيا الكرة طحن السعر

- أنواع آلات البناء المستخدمة

- قطع غيار كسارات syaji

- شركة بلجيكية لتصنيع مسحوق الحجر الجيري

- الخرسانة تأجير محطم في ديفون وكورنوال

- حزام سير مصر لكسارة الحجارة

- jaw crushers housing jan

- silica quartz rock for sale html

- extra heavy duty crusher for sale

- in indiaball mill for sale coal russian

- mining ball mill grinding

- mining equipment weel press

- price of tonr stone crushing plant in south africa

- iron ore mill scale purification

- indian suppliers of steel balls for ball mills

- knowladge about coal

- raw mill maintenance

- cement plants near to chittorgarh

- industrial trituradoras de ajo

- business proposal for quary mining mining

- granite quarry for sale in tamilnadu