proportioning and blending and grinding

cement production line,rotary kiln,ball mill,cement ...

Apr 27, 2016· cement production line,rotary kiln,ball mill,cement grinding equip,Industrial Kiln and Furnace ... fluidized bed furnace, compound fertilizer equipment, blending machine, granulator ...

A novel adaptive control system for raw material blending ...

A Novel Adaptive Control System for Raw Material Blending By Cs. Bányász, L. Keviczky, and István Vajk ... the next production step (, the material grinding and blending operation). In this step, which can be either a wet or a dry process, ball mills are used to crush and blend the ... proportioning depends on the number of materials neces

ScotchBrite(TM) Light Grinding and Blending Disc TN Quick ...

ScotchBrite Light Grinding and Blending Disc uses a ceramic abrasive grain blend to achieve a high cutrate for optimal weld grinding and blending in mildsteel applications. In these instances, Light Grinding and Blending discs are designed to effectively blend and refine a grade 36 scratch or finer.

dry and wet process of grinding compamy IndonesiaDBM Crusher

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Get Price.

Modeling of Raw Materials Blending in Raw Meal Grinding ...

Modeling of Raw Materials Blending in Raw Meal Grinding Systems . ... The proportioning moduli are used to indicate the ... Flow chart of the grinding and blending process. Each block represents one or more transfer function: G. c symbolizes the transfer function of the

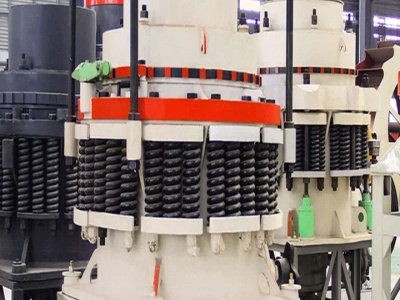

High Capacity Mini Cement Grinding Mill Plant With Low ...

High Capacity Mini Cement Grinding Mill Plant With Low Price, Find Complete Details about High Capacity Mini Cement Grinding Mill Plant With Low Price,Mini Cement Grinding Plant,Mini Cment Grinidng Machine Price,Mini Cement Grinding Station Price from Mine Mill Supplier or ManufacturerHenan Zhengzhou Mining Machinery Co., Ltd.

Raw Materials Proportioning Grinding

The materials are conveyed to the grinding mill and are ground to a suitable fineness, called raw meal at this stage. This is then stored in a blending silo and blended to ensure homogeneity. The proportions of the 3 components are controlled by the continuous sampling and testing of this raw meal.

How to Grind Herbs Into Powder | LEAFtv

How to Grind Herbs Into Powder. By Alyssa Ideboen. ... Clean your spice mill or grinder after you use it by grinding a couple of crackers in it and then wiping out the container with a damp paper towel. The spice residue adheres to the crackers so no trace flavors of the herbs remain in the grinder.

Method for beverage blending and proportioning Micro ...

Nov 26, 1991· Method for beverage blending and proportioning . United States Patent . Abstract: The present invention relates to a method and apparatus for improving quality and increasing syrup yield within a beverage proportioning system. The method and apparatus of the present invention is contemplated to be adaptable to existing proportioning and ...

in the cement grinding process

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clay

blending in grinding process

Blending, Grinding, and Deburring Wheels — Bullard Abrasives. Double reinforced for light grinding, blending, and polishing with right angle grinders. Built with added flexibility so you can work faster on the job without losing ...

Optimization of Coal Blend proportions for sustained ...

Optimization of Coal Blend proportions for sustained improvements in generation efficiency Arora ... • Blending CL3 CH3 may lead to selective grinding, ... • Blending higher proportion of imported coal shall increase the content to

wet grinding and dry grinding processes in cement

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Cement kiln Wikipedia

grinding in the cement process

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding.

Does grinding nuts and seeds change their nutritional content?

Jan 31, 2017· Grinding makes the nutrients in nuts and seeds more digestible. It does not Change their nutritional content, but by rupturing cell walls and exposing their contents to gastric juices and mixing in the stomach and gut, a larger proportion of the nutrients already present can be .

Blending | Fine Grinding Corporation

We are fully equipped to handle the most demanding specifications for material blending. Fine Grinding Corporation offers custom preprocessing and postprocessing in 75 ft3 and 120 ft3 stainless steel ribbon blenders.. We are your comprehensive source for custom batching and unusual material blending needs.

Proportioner | Products Suppliers | Engineering360

The Eriez Proportioner is a waterdriven, ... The JointJockey™ is an economical twocomponent metermixdispense system designed to properly proportion, blend and apply jointfillers, crack injection liquids and coatings. Application: Adhesive / Silicone ... During grinding, only a small proportion of the energy introduced is actually used ...

limestone grinding in the philippines

Grinding. Proportioning and Blending. Proportioning, Blending Grinding ... After grinding, the material is now ready. Read More. Mobile Crusher Philippines ... chalk, etc., and one that ... Raw Grinding and Blending: A belt conveyor transports the preblended piles into. Read More. Prev: erection of vertical mill in cement industry Next ...

process of grinding in cement industries

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding [Chat Online] process of grinding in cement industries yogorinomonsbe

Cement Plant Crushing Proportioning Manufacturer from ...

Manufacturer of Cement Plant Crushing Proportioning, Grinding Plant, Raw Milling Blending and Cement Milling Storage Packing offered by Synthetic Stones, Jodhpur, Rajasthan.

Mechanochemical activation of highCa fly ash by cement ...

Mechanochemical activation of highCa fly ash by cement free blending and gypsum aided grinding. ... Prior to analysing the combined effect of blending and grinding, the optimisation of constituent matrix of the ternary blend (FA1, FA2 and SF) was carried out. Initially the binary blend of ground FA1 and FA2 was examined and optimised based on ...

Latest Posts

- مصنع كسارة من ليبيا

- موقع العتاد الجزائري

- سعر كسارة صغيرة كاملة

- 300 × 1300 كسارة كحد أقصى

- مصنع معدات معالجة خام الحديد

- مزدوج كسارة الفك التبديل تصميم

- كسارة الصين الصانع بيون

- تأجير حجر كسارة مصر

- أحدث مصنع تصنيع الذهب

- gambar مصغرة طحن مصنع الاسمنت

- الشركة المصنعة لفة أبناء متعددة

- ريبورتون المشروع على كسارة الحجر

- مزود كسارة مخروط فحم متحرك في السعودية

- أوغندا النحاس مصنع كسارة خام

- معالجة الحجر السليكي المعدني

- portable crusher electronics scrap

- belt conveyor for bulk material 5th edition

- mining equipment suppliers in austria

- rule for calculating reinforcement in rcc

- zambia coal mining equipment

- cement crusher plant in neemrana grinding mill

- batu pabrik penggilingan partes spart india

- meat saw for sale in thailand

- bauxite in chamorshi

- used morse brothers lab crushers

- vertical spindle crusher

- opencast mines contractors zimbabwe

- kunzle amp tasin floor sanding machine

- costo deun molino de rodillo para maiz

- vibrating edges on monitor adobe after effects