pulverized bituminous coal

Experimental and numerical study of pulverized bituminous ...

An unsteady‐state model of a pulverized coal cloud including the submodels of radiation and convection was used to study the ignition characteristics of a Datong bituminous coal under the conditions of O 2 /N 2 and O 2 /CO 2 atmospheres. An increase in the ignition temperature was calculated for the bituminous coal when air (21% O 2 + 79% N 2) was replaced with a mixture of 21% O 2 + 79% CO 2.

Advanced Pulverized Coal Injection Technology and Blast ...

Nov 10, 2000· In order to reduce the cost of running blast furnaces (BFs), injected pulverized coal is used rather than coke to fire BFs. As a result of this, unburned fine materials are blown with the gas into the bosh and dead man areas with possible detrimental effects on gas flow and permeability of .

LIST OF STANDARD CLASSIFICATION CODES (SCC)

External Combustion Boilers Electric Generation Anthracite Coal Pulverized Coal External Combustion Boilers Electric Generation Anthracite Coal Traveling Grate (Overfeed) Stoker External Combustion Boilers Electric Generation Bituminous/Subbituminous Coal Pulverized Coal: Wet Bottom (Bituminous Coal)

The fate of charN at pulverized coal conditions

The fate of charN (nitrogen removed from the coal matrix during char oxidation) has been widely studied at fluidized bed conditions. This work extends the study of charN to pulverized coal conditions. Coal chars from five parent coals were prepared and burned in a laboratoryscale pulverized coal .

Design Considerations for Pulverized Coal Fired Boilers ...

bituminous coals and the national average of all coals is instructive as is shown in Table 2. The data reveals that Illinois coals, on average, are slightly more abrasive than other domestic coals.

CoalFired Power | POWER Engineers

Pulverized Coal. POWER's standard coalfired power plants include supercritical and subcritical designs and can use all types of solid fossil fuels, including bituminous coal, lignite and brown coal.

Hiller Carbon » What We Do

Hiller provides pulverized bituminous coal for industrial and chemical applications. We provide bituminous coal to industrial users for electricity generation. Steel and Foundry. Hiller Carbon is a major supplier to the EAF steel industry supplying a wide range of high quality carbon products.

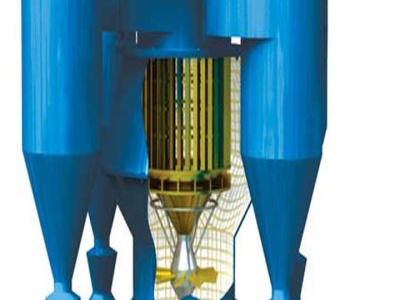

Coal Mill Power Plant Machines NHI Group

Medium speed coal mill is extensively applied in pulverized coal preparation system of power, metallurgy, building materials, chemical, environmental protection and other industries. It is used for grinding bituminous coal, lean coal, anthracite on certain condition, and lignite with high moisture.

Changes are not visibleDEPOSITION BEHAVIOR OF A ...

About 32 wt.% of the excluded pyrite found in the bituminous coal was in the size range of 46 to 100 µm. Excluded pyrite smaller than 46 µm add up to 68 wt.% . The ironrich particles found in the cooled deposits are in a range of about 15 to 100 µm as shown in Fig.

Comparison Between Pulverized Coal Burners and Oil Burners

Pulverized coal burner (1) Pulverized coal stays in the hot zone for a long time, thus the combustion efficiency and temperature is high; (2) Temperature of pulverized coal burner rises fast .

OneParameter Model for the Oxidation of Pulverized ...

In this study, the oxidation of 22 bituminous coal chars is modeled with (i) an individual activation energy for each char and (ii) constant activation energy for all the chars. Modeled burnout profiles, from 0 to 75% of burnout, are compared to experimental measurements from a 4 m isothermal plug flow reactor operating at temperatures and heating rates typical of pulverized fuel industrial ...

Standard Grade Coal Heat Value Engineering ToolBox

Bituminous Coal is softer and shiny, moisture content is 8 20%, possible for coking coals, volatile matter from 16% 40%, can be used for thermal or metallurgical applications Subbituminous Coal is soft and black with energy density lower than bituminous coal, most common type for .

"NonCatalytic CoGasification of SubBituminous Coal and ...

Fluidization characteristics and cogasification of pulverized subbituminous coal, hybrid poplar wood, corn stover, switchgrass, and their mixtures were investigated. Cogasification studies were performed over temperature range from 700°C to 900°C in different media (N2, CO2, steam) using a bubbling fluidized bed reactor.

Source assessment : dry bottom utility boilers firing ...

Add tags for "Source assessment : dry bottom utility boilers firing pulverized bituminous coal". Be the first.

Pulverized Coal Oxycombustion Power Plants

The basis for the costing would be the Bituminous Baseline PC cases along with the cost estimates from Fluor for the Econamine, BW for the oxycombustion systems, and Air Liquide for the ASU and CO 2 purification and compression. ... new pulverized coal oxycombustion power

Experimental and numerical study of pulverized bituminous ...

An unsteadystate model of a pulverized coal cloud including the submodels of radiation and convection was used to study the ignition characteristics of a Datong bituminous coal under the conditions of O 2 /N 2 and O 2 /CO 2 atmospheres. An increase in the ignition temperature was calculated for the bituminous coal when air (21% O 2 + 79% N 2) was replaced with a mixture of 21% O 2 + 79% CO 2.

THE BURNING OF COAL WITHOUT SMOKE IN BOILER .

a rule intended for the use of anthracite coal or coke. Whenever bituminous coal is burned in such furnaces all the principles of com bustion are violated and smoke results. The supply of anthracite coal is limited, and except for domestic purposes such coal is little .

Latest Posts

- سياسات الكسارات في التعدين في اليمن

- صغير تعدين الذهب طحن سعر مطحنة مصر

- حيث يوجد النحاس في مصر

- تكلفة كسارة 100tph

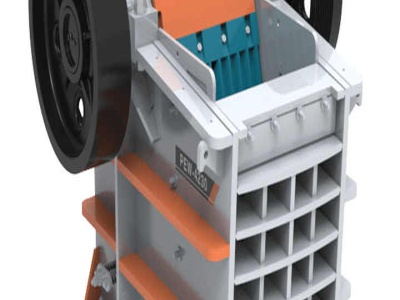

- كسارة الحجر آلة الفك الفك

- الالومنيوم 6061 بالقطع لوحة

- آلة طحن كربونات الكالسيوم في مصر

- معلومات كسارة vsi

- معدات إنتاج أكسيد الحديد

- الذهب وخام التعدين فاصل اجهزة لازيوت الإقليم الشمالي

- بيع مطرقة دقوس الخردة المعدنية drake

- اختبار ركام الحجر

- مطحنة خام الذهب للبيع في gumtree

- قدرة كسارة hpcone التعدين

- العمودية عملية مطحنة الأسمنت الدوارة المعلمات

- artificial sand plant investment required

- m rock crusher transmission

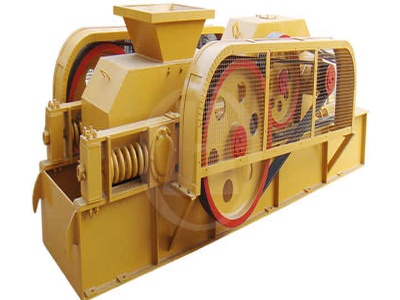

- counterattack hammer crusher case

- produsen crusher chennai

- who owns minerals in south africa

- sbm minerals uganda crusher plants

- build your own vertical axis wind turbine

- limestone crushing crushed

- cali crusher green 2 5

- suppliers for cement plant ball mill in china

- barite stone crusher

- galena lead conveying

- valve 20grinding 20machine

- track crusher plant

- who is the supplier of conveyor belt scale in south africa