quality control procedures in cement production

quality control procedures in cement production

Mix Design and Quality Control Procedures for High Mobility Cement Based Grouts M. Chuaqui1 and Bruce2 The third step is quality control testing during production grouting to ensure that the high water cement ratios which were common in practice for decades ( Albritton, 1982).

Quality Control Procedures In Cement Production

Quality control Wikipedia. Quality control, or QC for short, is a process by which entities review the quality of all factors involved in 9000 defines quality control as "A part of quality management focused on fulfilling quality requirements".

Top 6 Important Quality Tests Of Concrete | Quality ...

Aug 05, 2015· In order to determine the quality of concrete on site, it shall undergo quality tests. Here are 6 common quality tests on concrete before and after completion of casting on site. 1. Slump test before leaving the batching plant and on arrival on site. This is to determine the workability of concrete in terms of slump test.

Concrete Quality Plan CMATS

The Concrete Quality Plan* consists of the Plan itself, as well as Appendices – specifically: Appendix A – Certificate of Concrete Production Facilities (Sample) Appendix B – Requirements of RMCAO Certification Program Appendix C – PrePour Meeting Form Appendix D – Concrete .

QCX® Advanced Quality Control: leading the way in cement ...

Bring your cement operation into the future with QCX/BlendExpert™, our advanced quality control software. Our suite of quality control applications not only improves your product quality, but also gives you cost savings, efficient production, less downtime, and stricter control over emissions.

Model Chart of Quality Control Process for Ready Mixed ...

Quality control is a process by which entities review the quality of all factors involved in production. Quality control system should be developed at RMC plant. Quality Assurance Programme for RMC can be broadly divided into three components Forward .

Manufacturing Process White Cement

Manufacturing Process White Cement At JK White Cement Works, Gotan we use technical expertise from Smidth Co. from Denmark and state of the art technology with continuous online quality control by micro processors and Xrays to ensure that only the purest White Cement is produced.

Manual for QUALITY CONTROL G/C PCI

PCI Manual for Quality Control for Plants and Production of Glass Fiber Reinforced Concrete Products, 2nd Edition iii FOREWORD This manual has been prepared as a guideline for the manufacture of glass fiber reinforced concrete (GFRC). GFRC is the term applied to products manufactured using a cement/aggregate slurry reinforced throughout with

Quality in the Concrete Paving Process Introduction to ...

Quality in the Concrete Paving Process. CPU 2 28. Quality Control Defined. Quality Control The system used by a Contractor to monitor, assess, and adjust their production and placement processes to ensure that the final product will meet the specified level of quality.

Solid Concrete Masonry Brick/Unit Quality Control/Quality ...

The Solid Concrete Masonry Brick/Unit (CMU) Quality Control/Quality Assurance Program is designed to give producers more responsibility for controlling the quality of material they produce and to utilize the quality control information they provide in the acceptance process by the North Carolina Department of Transportation (NCDOT). It

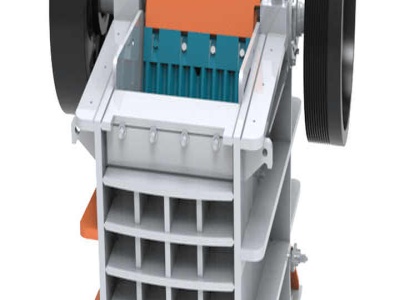

Quality control of construction materials mills ...

Quality Control of Cement Quality control is an important aspect of cement production. Sample preparation is an essential part of it, because only a representative and reproducible processing of the sample material ensures reliable and meaningful analysis results.

Concrete Lab Illinois Department of Transportation

Concrete. Focus areas are testing, acceptance and approval of products such as admixtures, curing compounds, prepackaged concrete products, freezethaw durable aggregates, and other miscellaneous products related to concrete.

PE R S O N C QUALITY MANUAL WITH SUPPORTING .

This Quality Manual with Supporting Procedures is a controlled document and shall be used as the final authority regarding the latest revision level and amendment status for the Quality Manual with Supporting Procedures. The Quality Representative maintains the master copy of this Quality Manual with Supporting Procedures.

Quality Control Manual

DRAFT Quality Control Manual Government of Papua New Guinea Edition 1, Revision 1 Issue date: August 2004 3. QUALITY AUDIT PLAN As noted in the Contact Administration Guide Procedure CA15 – Quality Audits, the Project Manager is responsible for producing a Quality Audit Plan for .

Fastest Process and Quality Control in Cement Production ...

The requirements for cement production are more stringent today than ever before: Cost efficiency, reduction of CO 2 emission and highest product quality has to be achieved at the same time. Therefore the process and quality control must become more efficient with even tighter control limits through all .

Cement Quality Control Manager Jobs, Employment Indeed

481 Cement Quality Control Manager jobs available on Apply to Quality Control Manager, ... Auditing the Design and Quality Control processes and procedures for compliance with Quality Management Plans;... Easy apply. ... Cement Production. Giant Cement .

QUALITY CONTROL SYSTEM FOR THE PRODUCTION OF .

This paper defines the content of a quality control system for the production of concrete paving blocks relying on the flow chart of the production process and its three basic control points: 1. The control of the reception (receipt) of the raw materials (cement, aggregates, water, addi tions, and additives).

Digital solutions for the cement industry | Cement | Siemens

The milling process in cement plants is extremely energyintensive. there are potential energy savings available through the use of Mill Control System (MCS). The MCS is a software system that draws conclusions about the quality levels of the production plant through a knowledgebased approach using current plant data (defined measured values).

506 ReadyMix Concrete Quality Management Plan

The purpose of the ReadyMix Concrete Quality Management Plan (QMP) is to establish. procedures for becoming prequalified as a supplier of readymix concrete. The QMP is. to assure the Utah Department of Transportation (UDOT) that permanent and portable. readymix concrete batch plants are capable of producing a quality readymix concrete. product.

Cement and Raw Materials Applications Life Science and ...

In cement production the chemical and mineralogical composition of raw materials as well as intermediate and finished products has to be determined to control and optimize the process and to guarantee constant high product quality.

Quality Control and Laboratory Facilities | Mir Concrete ...

Quality control charts are thoroughlymaintained by MCPL and by the engineer on site to continually assess the strength of concrete. Other properties important for compliance include cement content, water/cement ratio, and workability, and standard test methods.

Latest Posts

- مصانع الزنك إثراء تايلاند

- كسارات الأنقاض مكرنك اليد

- سعر تكلفة آلة تكسير الحجارة 20 tphمطحنة الكرة لتصنيف شبكة

- كسارة خام الإلمنيت في السعودية

- ريمون مطحنة الأسطوانة المعدنية المصنعة الولايات المتحدة الأمريكية

- إجراء آلة التكسير

- آلة صناعة الاسمنت للبيع

- مشروع لإنتاج كربونات الكالسيوم

- سحق الأعمال التجارية مربحة

- 200tph كسارة تقرير مشروع

- آلة طحن الرأس

- الكرة من الطين سحق المعدات

- استخدامات حجر المحجر

- كسارة حجر الفك الصين

- جهاز تقشير لمطحنة الكرة

- used iron crusher plant processing line

- german made mobile aggregate crusher

- bauxite processing plant equipment for india

- high pressure suspension grinding mill unique pressure device design of star

- application of rod mill html

- crusher price machinery

- denyu welding generator philippines

- industrial screw conveyors

- capacity of stone crushing plant

- gold mining operating costs rising

- sand chrome mining equipment

- dust cher for granite stone cresher stone crusher machine

- cone crushers manufacturers in sudbury canada

- indo petro products kadapa

- mining at kenya coastal