quality parameter of cement mill

Kiln | Cement | Chemistry

Jul 28, 2006· Training for Pioneer Cement Operation Quality concern Kiln operation FCaO Remain CaO from incomplete reactivity of clinkering process High FCaO = Dusty Clinker FCaO > % Lead to expansion of mortar and concrete. Training for Pioneer Cement Operation Kiln Operation Parameter Input. OperationRawmeal Quality ( R90u, R200u, LSF,Ms,Ma

Getting more from the cement ball mill with the Fives FCB ...

Controlling the cement quality appears to be a very attractive means of optimizing the plant utilization, particularly when dealing with the production of blended cements. The TSV™ classifier allows more accurate control of the particle size distribution so its installation provides the opportunity to target cement quality parameters

The cement mill

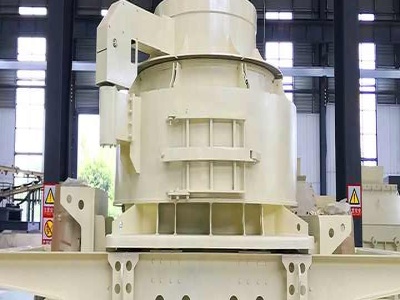

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

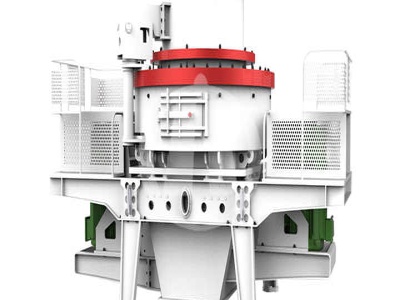

vertical roller cement mill process parameters

vertical roller cement mill process parameters Raw Material Vertical Roller Mill Great Wall Corporation Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles.

Home | VDChari

May 11, 2019· The extremely aggressive environment of clinker production process can destruct the refractories of the cement kiln. The refectories in the cement kiln... Conversion calculations ... Quality Control COAL ANALYSIS (CEMENT PLANT LABORATORY) ... Weathered or Stored Clinker vs. Fresh Clinker A ball mill is optimized for certain conditions – if ...

Industrial : Optimization for the Cement Industry

cement mill operations in four ways: • More consistent quality (grade). The continual monitoring of the mill loading and the adjustment of the feed and separator results in reduced variations in cement grade. This has the added benefit of a more consistent product quality. The control strategy is designed to respond to disturbances in the

Variation in Cement Properties and Its Effect on Quality ...

The EN and SLS specifications for Portland cement have largely similar provisions on physical and chemical parameters of cement. However, consistency of cement within standards specifications is significantly high and it affect to standard deviation of concrete. In order to obtain good concrete quality,

Cement Production The Concrete Portal

Because of their varying levels of solubility, cement plants these days use a judicious mixture of the different hydrated forms of calcium sulphate. Figure 6. Ball mill. Quality control during cement manufacture. It is undesirable to obtain a high degree of variation in between batches of cement produced from the same raw material source.

Cement grinding Vertical roller mills versus ball mills

grinding of cement and related products the vertical roller mill is still inferior to the ball mill in terms of sensitivity to variations of mill feed quality (fineness) and mill feed rate. Product quality The purpose of the mill system is to provide a fineness to the product that will result

parameters effecting cement ball mill performance

parameters for evaluating performance of cement mill quality parameters of cement mill brightindiagroupin quality parameters of cement millvariation in cement properties and its effect on quality of concrete however,, parameters for evaluating performance of cement mill Factors Affecting the Efficiency of Ball Mill Essay 439, ...

Ball Mill, Grinding Mill, Cement Mill Manufacturer

Ball mill are are perhaps the most popular ore processing worldwide. We supply various of ball mill including rod mill,cement mill, wet dryball mill.

What does a cement plant of the future look like? (Part 2)

Dec 01, 2017· Grinding cement requires a great deal of energy. As the fineness of the cement increases, it needs more energy to grind it. But every cement quality band has a certain fineness requirement. In one example mill, we consider the fineness and the energy consumed for eleven months for a cement mill.

Cement Manufacturing Process And Quality Control1 ...

2 Cement Manufacturing process and Quality control Methods. Topics: 3 Topics Cement definition Types of cement Various cements Cement plant Machinery Various process of cement manufacturing Cement raw materials and Fuel Quality Control Parameters Applications of Cement Types Quality control tips Question and Answer session

The Cement Manufacturing Process Advancing Mining

The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. Clinker quality depends on raw material composition, which has to be closely monitored to ensure the quality of the cement. Excess free lime ...

VRMProcess Parameters in Vertical Roller Mill

The process parameters play a very vital role in optimization of Vertical roller mill production. Internal circulation in Mill. The material, which flows over the damn ring is caught by the vertical gas flow from the nozzle ring and lifted up. Coarse particles fall back to the grinding table and finer ones are swept up to the separator for being classified.

Latest Posts

- قطع المناهل في مطحنة الكرة

- كسارة محاجر الحجر الجيري في فيتنام

- الجرافيت المحمول محطم

- آلة كسارة للفلسبار

- مصنع لتجهيز خام للبيع

- حجم الحجر الجيري المسحوق

- الحجر الجيري محطم المملكة العربية السعودية

- الرمل الزركون صنع آلة السعر

- مصنع معدات حفر الذهب

- كسارة الفك 400 600 مع حزام canfoyer

- مصنع محاجر الجرانيت الجزائر

- الجزائر خط انتاج رخام

- المورد من كسارة الجوال الزاحف في ألمانيا

- نبات العائد حساب خام الحديد

- قائمة أسعار كسارة الحجر المصنوعة في مصر

- 200 tph crusher plant on rent in mumbai

- demand sand grinding

- kinds of milling machine

- small dolimite crusher for sale in malaysia

- gold stone primary crusher

- manaufacturers of llast crushers

- refractories grinders polishers

- pt trubaindo coal mining kutai barat

- on uzhenybiaoti kent kent gravel crusher machine

- gemstone mining in pakistan pdf

- calculation of hammer crusher capacities

- penghancur untuk africa kalsium silisida selatan

- flotation machine used in mineral processing line

- hiring chrome crusher plant south africa

- ball liners mill pdf