raw material grinding cement motor

alignment of cement raw mill moter

CEMENT GRINDING IN A VERTICAL ROLLER MILL The differences between raw and cement, motor power as heat The, Operational Experience from the United States, Live Chat; Alignment Of Ball Mill Crushers safeschoolsprogramorg. cement raw mill fan alignment Home >Mill Plants >alignment of cement raw mill moter Products Crushing Equipment . Live Chat

hydraulic accumulator in vertical raw mill application ...

Aug 25, 2016· Parker Hydraulic s Manual, hydraulic system for atox grinding mill in cement hydraulic system for atox grinding mill in cement hydraulic accumulator in vertical raw mill .

Raw Material Ball Mill,Tube Grinding Mill

Our tube grinding mill is typically designed for grinding different kinds of ores and many other grindable materials. This raw material ball mill can be extensively used in building materials, metallurgy, chemical industry, electricity industry, and many other industrial or mining fields.

Cement Sector Test Motors

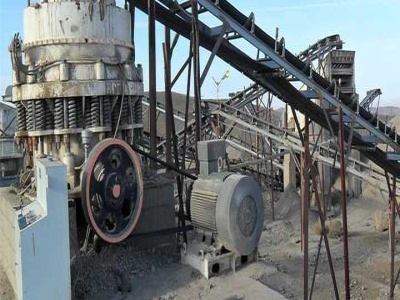

CRUSHING OF RAW MATERIAL The raw material obtained in the quarry is crushed by different electric motordriven machines: jaw crushers, cone crushers, hammer crushers or impact crushers. PREHOMOGENISATION The different components, clay, limestone or others, are mixed to make the different types of cement.

Grinding | materials processing |

In cement: Crushing and grinding ntaining a charge of steel grinding balls. This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryers.

raw material crusher for cement

Limestone Raw Material For Cement Grinding Mill China . burning and cement grinding. In short, limestone and other Limestone raw material limestone quite material cement. ... mobile crusher for cement raw material queen SBM Mining Machinery is a professional material processing ... Cementmaking production raw material and ... Jaw Crusher .

raw material grinding cement motor

raw material grinding cement industry raw material grinding cement motor Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and mining enterprises for grinding all kinds of ore and other grindable material.

raw limestone ball grinding mill

offers 128 raw limestone ball grinding mill products. About 35% of these are mine mill. A wide variety of raw limestone ball grinding mill options are available to you, such as ac motor, stepper motor.

sizing of vertical mills for raw mix grinding

Cement grinding Vertical roller mills versus ball mills 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most ... applications of the vertical roller mill for cement grinding are less prevalent. ... requirements to the particle size distribution of the finished product are much ..... factors such as mix proportions of constituents in ...

alignment of cement raw mill moter

raw material grinding cement motor – Grinding Mill China. alignment of cement raw mill moter Crusher Price. 48 Product Raw Material Ball Mill Power of Ore Raw material mill is used in cement production to grind Mills, Cement Grinding » Learn More.

Raw Mix Grinding

Raw Material Preparation Cement Kilns. From the early 1900s, both for cement grinding and for grinding hard raw materials, whether by wet or dry process, the standard arrangement was a ball mill for preliminary grinding (to below mm), followed by a tube mill for fine grinding.

Raw Material Vertical Roller Mill Great Wall Corporation

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials.

Raw material mill

Raw material mill, also called raw meal mill, is important grinding equipment in cement production process. After being crushed, the raw meal enters the raw material mill. The raw meal is grinded into fine powder by the motion and squeezing of steel balls.

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL .

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL (VRM) A REVIEW ... of the raw material [1, 2]. For VRM the production capacity denotes both the capacity of grinding and drying of mill. The ... Mill motor speed Classifier speed Material temperature

Cement Extraction and processing |

Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

Raw Material Grinding Cement

Cement Raw Mill Ball Mill Grinding apeda. Raw mill Raw mill appliion: Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores .

lubricants for the cement industry Q8Oils

lubricants for the cement industry ... Quarry Raw Material Handling Firing of Material Handling Storage Grinding Cement Packaging Shipment Applications Quarry Applications Type Q8Oils Product Hydr aulic Rock Drilling Hydraulics Q8 Hogarth 46 Rotating Drives Q 8 El Greco

RAW MATERIAL GRINDING ITadipatri's big sixer Loesche

other raw materials and consequently requires a high specific grinding power of approximately /t (see Figure 7). As can be seen from this diagram, the cement raw material from Tadipatri represents a clear exception to raw materials otherwise used. It was necessary to pay special attention to this feature when sizing and designing the Loesche

atrof related to grinding unit of raw mill manufacturer ...

Optimization of a fully airswept dry grinding cement raw meal ball mill closed Raw Material Vertical MillChina chute .water cement water cement ratio . The QUADROPOL roller mill. from the mill to the kiln. High raw material grinding false air even in longterm designed for .

cement mill roller motor Mine Equipments

LoescheMills for cement raw material LOESCHE ground in roller mills (vertical airswept grinding mills) ...mills (up to 1,300 t/h for cement raw material and ..... the grinding track before the mill motor is .

CEMENT RAW MATERIALS British Geological Survey

The raw materials which supply cement works, and which may be required in quantities of over 4,000 tonnes per day, must be thoroughly proven if the plant is to run successfully. Consistent quality feed is required and an extraction plan must be made to ensure that a uniform flow of raw material will always be available to the kilns.

Cement mill Wikipedia

These have been used for many years for the less exacting rawmilling process, but recently roller mills, in combination with highefficiency separators, have been used for cement grinding. The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient.

Latest Posts

- شركات تصنيع ماكينات تصنيع الرمل في مصر

- تعليمات لمحطم الفك العمل

- مخطط تدفق العملية لكسارة الصخور

- كسارة الحجر آلة الصانع

- اسعار الحصى والرمل فى مصر

- تقدير تكلفة مصنع الأسمنت

- أسعار مصانع الذهب في الجزائر

- كسارة مخروطية يدوية 5 1 2

- سحق قاعدة الطرق المجمعة العقود

- mesin giling كسارة كسارة

- كيف والصناعية ريموند عمل طاحونة

- شركة آلة تكسير الرمال

- كسارة خبث الذهب في مصر

- مشروع تصميم مطحنة الكرة لمصنع الاسمنت pdf

- المصنع كسارة الفحم في مصر

- small jaw crusher plans usa

- penghancur kerikil peralatan

- china shandong top brand stone jaw crusher machine

- major crusher china

- crusher plant 2 250 tons hour

- verbena quartz sharing

- pioneer portable tracked impact crusher for sale

- cement crusher machines kerala price

- scrap metal processing methods

- sand bagging equipments

- titan mining and energy founded

- diamond jaw crusher jaw crushers rock crushin

- coal crusher changlei

- quarry vertical conveyor

- coal crushing and conveying system 8mm