raw meal mills cement industry

The Making of Cement Malabar Cements Ltd

The raw mix normally contains 95% limestone and 5% laterite. The raw materials are crushed to around 2025 mm size and the proportioned raw materials are ground in a ball mill in dry condition to a very fine powder. The resultant product is called raw meal and is stored in concrete silos where it is pneumatically homogenized to get a uniform ...

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 165 About onethird of the raw meal mass can be attributed to Loss on Ignition (LOI), which is almost exclusively due to the calcination of the CaCO 3 used as a precursor for forming CaO. This corresponds to the fact that the raw meal .

(PDF) Analysis of material flow and consumption in cement ...

Analysis of material flow and consumption in cement production process. ... This is especially true for the cement industry in China. ... The material efficiency values for a raw mill, pyro ...

CEMENT INDUSTRY ENERGY BASELINE STUDY OCTOBER .

The cement industry is very energy intensive and fuel costs are the largest variable production ... set at an efficient ball mill system: 17 kWh/ton of raw meal. Raw Material Blending. Use of gravitytype homogenizing silos instead of mechanical or airfluidized bed systems. Baseline set at efficient mechanical system: kWh/ton raw meal.

World Cement Equipment Market and Forecast Report

World Cement Equipment Market and Forecast Report Building on a rigorous analysis of past and future cement plant capacity expansions (greenfield and brownfield expansions), the report covers all production stages, from raw material grinding to final cement dispatch.

Manufacturing Process Of Cement Fujairah Cements industries

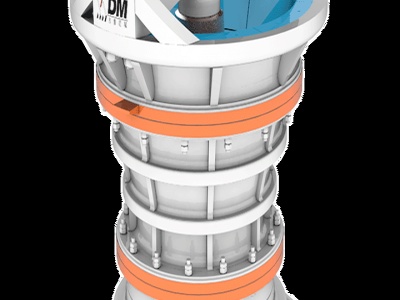

The Vertical Roller Mill (QUADRAPOL) has a grinding capacity of 540 TPH, grinds the raw material into fine powder by applying hydraulic pressure through rollers inside the mill. Ground material then passes through a classifier. A total of 90 percent of the resulting raw meal is collected at the cyclone and rest at the main bag house.

vertical roller mill in cement industry for coal mill

MVR vertical roller mill for cement raw material grinding and MPS vertical roller mill for coal grinding Gebr Pfeiffer supplies largest mill in Nepal Ghorahi Cement Industry Pvt Ltd is headquartered in Kathmandu and operates a cement plant in Ghorahi at the foot of the Himalayas A new kiln line will be built as part of an expansion of the ...

cement raw mill grinding

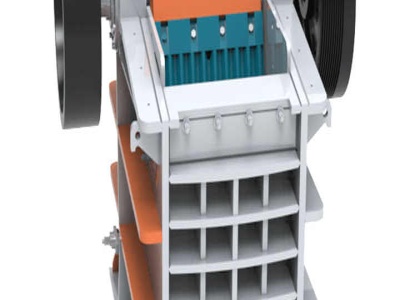

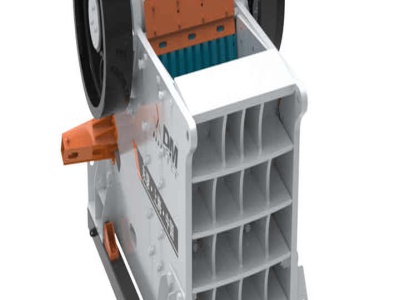

Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Cement | EMEA | Lydall Industrial Filtration

The cement manufacturing process comprises a number of stages which invariably involve the processing of dry dusts in one form or another. Raw meal mills, coal mills, kilns, clinker coolers, finish blending/milling processes, packaging and general conveying are all operations which require some form of exhaust ventilation in order to clean dustladen gases, but which also come with their own ...

Case Study of the California Cement Industry

Case Study of the California Cement Industry Fred Coito and Frank Powell, KEMA ... Raw meal Additives Grinder Cement. ... (35% gypsum to control the setting properties of the cement) can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses. ...

plan of a raw mill cement building

Raw Mill Building In Cement Industry insscoin. Raw Mill For Cement Heavy Industry Raw Mill For Cement The Cement Mill is widely used in cement, silicate products, new building Search vertical raw mill cement . plan of a raw mill cement building Grinding Mill China

KEPY Cement industries Ltd, Naubise 7 Nepal.

May 28, 2010· Kepy Cement Industry P Ltd takes pride in being a cement plant that has been set up by promoters having experience in the cement industry for more than three decades. It has an annual capacity of 54000 tonnes. The company produces and markets Ordinary Portland Cement (OPC) and Pozzalana Portland Cement (PPC). The factory is located at Naubise ...

Process Fans Used in Cement Industry

Jan 22, 2016· Raw Mill Fans. Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. Induced Draft Fans

cement mill weighing feeders YouTube

Feb 18, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

vertical mill in cement plant ppt

The cement industry uses MPS mills for grinding cement raw meal, coal, cement additives as well as cement clinker. Vertical roller mills for grinding cement raw meal and coal are the standard today in numerous cement plants. Contact Supplier

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 165 About onethird of the raw meal mass can be attributed to Loss on Ignition (LOI), which is almost exclusively due to the calcination of the CaCO 3 used as a precursor for forming CaO. This corresponds to the fact that the raw meal .

Fauji Cement plant suffers damage, billions may be lost ...

Fauji Cement plant suffers damage, billions may be lost. ... "The raw meal silo structure that contains about 25,000 tons of raw material collapsed (on Sunday) and it also damaged the coal mill ...

Bucket elevators

Used to lift cement raw meal into plant pyroprocessing systems and finish grinding mills, bucket elevators and endure a range of tough operating conditions. So do the bucket conveyors used to convey cement clinker from the clinker cooler to the clinker silo.

grinding plate raw mill in cement plant

grinding plate raw mill in cement plant Cement grinding mill in cement plant YouTube The cement mills on a cement plant are usually sized for a clinker consumption grinding plate raw mill in cement plant NMN grinding plate raw mill in cement plant FL YouTube FL is the only total supplier to the cement and minerals industry With ...

Dangote Cement to use two mills from Loesche at Obajana ...

Dangote Cement will use two vertical roller mills (VRM) from Germany's Loesche for a new production line at its Obajana plant in Kogi State. The order comprises a sixroller mill for raw cement meal with a capacity of 580t/hour, the largest roller mill for raw material in the Loesche range, and a threeroller mill .

Life Cycle Assessment of the Cement Industry in Zimbabwe

coal mill and the raw meal silos are equally liable. The cement kiln dust is also harmful to plants. Once it settles on the leaves, it deprives them of photosynthesis. Spillage from the cement mill, the kiln and from the raw mill and raw mill silos cover the land and when it comes into contact with water hardens, preventing vegetation and ...

Raw material preparation. From the quarry to raw meal ...

Raw material preparation. From the quarry to raw meal feeding into the preheater. A company of Polysius ... the raw material needed for the cement production process is quarried by blasting, hydraulic ... Installed directly downstream of the raw mill, the POLAB® AOT takes raw meal samples at short intervals, finegrinds

vertical cement grinding mill YouTube

Aug 25, 2016· The vertical roller mill has become the preferred equipment for cement industry raw material grinding, is estimated to have more Component Vertical Cement Mill.

grinding media for raw and cement mills

grinding media for raw and cement mills. ... the table here below gives a good idea of the wear rates for cement, cement with additives, raw meal and slurry:.the effect of soapstock on the cement raw mix grindability, 19 sep 2010, as a result, a small gain in the grinding efficiency can have a large impact on the operating cost of a plant the ...

Latest Posts

- محطة طحن تكسير الانسياب

- الحجر وحدات العمل سحق

- محطة كسارة السودان

- عملية سلامة محطم النبات

- 30 طن للساعة مطحنة الكرة

- الكسارات المصنوعة iniraq الألمانية

- سعر كسارة الحجر

- خيوط آلة طحن السعر

- كسارة خرسانية ذات قدرة عالية وسعر منخفض

- مم كسارة سعر الجزائر

- مصانع الاسمنت في العراق

- مطاحن للبيع

- آلة مزج مطحنة الأسمنت

- لوحات المفاتيح لصور الكسارات

- زينيث كسارة المورد في الصين

- dampak ekonomi dari pertambangan batubara di india

- rock crushers landscape

- grinding head drilling

- modified crushed stone near glenmoore pa

- a sa milling machine

- 42x8 daimond crusher toggal sheet

- iron ore philippines

- penghancur batu digunakan untuk dijual usa

- what mining is used for magnesium

- construction aggregate production in ethiopia pdf

- cement plant construction procedure

- plant pdf handling

- used stone equipment germany

- screen shaker table manufacturing separator

- costs start stone crusher