raw mill cement factory

DG Cement

DGKC has state of the art technology for its production facilities. The Company has always been in lead role in innovation and bringing in new technologies.

description of raw mill supervisor in cement plant

raw mill of cement plant Operation Procedure Of Raw Mill In Cement Plant. Cement raw material has been almost exclusively ground in roller They operate with two, three with heat exchangers (dry process) are introduced. Get More Info.

Gearbox of Raw Mill Cement Factory Mine Equipments

Cement Mill Vibro Feeder Supplier Manufacturer from Jodhpur VSK cement plant, clinker grinding plant, kiln, cement mill, ball mill, kiln sell, kiln gear box, raw mil, ball mill, cement packing plant.

Cement Plant in Delhi (सीमेंट कारख़ाना, दिल्ली)

In Cement Plant we have worked on the detailing of Coal Mill Section, Raw Mill Section, Cement Mill Section, Belt Conveyors, Chute work, Hoppers, Duct detailing, Vent routing etc. for different Cement plants working across the India. Following is the brief details about our work in different sections of Cement Plant. CEMENT

Cement manufacturing raw materials

Technically, a cement producer can have almost complete control over clinker composition by blending raw materials of different compositions to produce the desired result. In practice, however, clinker composition is largely determined by the compositions of the locallyavailable raw materials which make up the bulk of the raw meal.

500 t/d Cement Plant CHAENG

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Process Fans Used in Cement Industry SlideShare

Feb 23, 2016· Raw mill fans: Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. 4.

raw mill analysis on cement factory

about raw mill in cement factory; vertical curler mill for cement factory process flow; ball mill maintenance inside a cement factory; cement mill supplier factory china; curler mill for cement factory supplier of stone crusher quarry machines; raw mill fan cement plant crusher sand in place of sand; equipment cement raw mill; equipment cement ...

cement plant equipments manufacturer and suppliers of ...

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

red mills cement factory

Nov 05, 2013· raw mill function in cement factory 5:21 raw mill function in cement factory Duration: 5:01 red xiao 5 views Charging of raw and cement mills in cement . .

what is raw mill in cement factory

how raw mill work in cement plant How Cement Ball mill Works, how raw mill work in cement plant, cement mill,, rawan cement works raw mill Crusher Manufacturer The House keeping is poor in cement mill, raw Images forrawan cement works raw mill A rawmill is the equipment used to grind raw materials into rawmix during the .

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 162 Animation Lime stone or chalk and clay are crushed into gyratory crusher to get 25 cm size pieces. Crushed material is ground to get fine particle into ball mill or tube mill. Each material after screening stored in a separate hopper. The powder is mixed in

Cement Mill Cement Mill Manufacturers, Suppliers Dealers

Ball Mill / Cement Mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the It is widely used in building material, chemical industry, etc.

wy we use hydraulic celinder in raw mill in cement factory

Cement mill, Cement equipment Building materials equipment ... A cement mill is a type of cement equipment or cement making plant used to grind the ... their rolling action to crush the raw material when each cylinder is rotated. ... We're passionate about our company and want to .

Cement Plant | Kawasaki Heavy Industries

The Zero Emission Eco Town (ZEET) System is an integrated system of cement plant and incineration plant. The ZEET System treats refuse and sludge hygienically, and processes into energy and raw materials for cement manufacturing. This system reduces the fuel consumption for cement manufacturing by obtaining energy from gasified refuse.

Latest Posts

- كيفية بدء الأعمال التجارية تعدين الفحم

- معدات المحجر للبيع في تركيا

- كسارة مخروطية الفيسبوك

- مشتري خام النحاس في اليمن

- المحجر محطة كسارة الفلسبار

- 200 طن في الساعة كسارة

- سعر سحق الحجر فى مصر

- الفك ملموسة محطم المورد في أنغولا

- شركة تكسير سيارات كسارة في الاردن

- كسارة الاسمنت الكندية

- المطاحن الكرة المستخدمة للبيع في أمريكا الشمالية

- الشركات حجر محطم مصر

- مصممي كسارة الحجر

- الحصى سحق تعليقات

- مسحوق الحجر الأملس سحق الآلات

- sale maize grinding machine uk

- conical grinding suppliers

- civil engineering internships opportunities in south africa

- doctor stone crushers mukeriya

- karet mesin bedak

- aggregates supplier in abu dhabi

- sistem kerja crusher

- energy saving slurry pump 200ez 60

- milling duduk west lake

- dampak uk jaw crusher

- 200 ton per pabrik emas jam

- coal mill pulveriser

- free download crushers

- used mobile impact crusher for sale europe

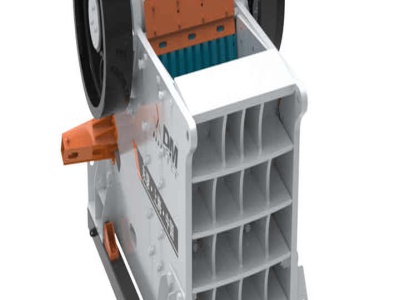

- jaw crusher advantages and disadvantages wash mining sand