redspot causes in rotary kiln in cement factory

rotary kiln red spot

redspot causes in rotary kiln in cement factory. rotary kiln red spot redspot causes in rotary kiln in cement factory red spot on rotary cement kilnqualitymachines to handle the demanding requirements of cement plant operationssick s rotary kiln inletsimulation of rotary cement kilns .

coal rotary clasifiers in india

coal rotary clasifiers in india apron feeder vibrating feeder in coal handling plant in Vadodara, Gujarat, Coal Crusher Business . get quote. rotary crusher in germany coal rotary classifiers in india; rotary drum screen vendor; redspot causes in rotary kiln in cement factory; rotary sand washing machine; primary rotary ...

cement kiln reactions

Overview of Cement Production Cement is an ... is heated in a rotary kiln to induce a series of complex chemical reactions ... emission factor for Cement Kiln ... Get Price; Modeling of Rotary Cement Kilns: Applications to Reduction ... Rotary cement kilns are used for converting calcineous raw meal into cement clinkers.

Identification of Nonlinear Predictor and Simulator Models ...

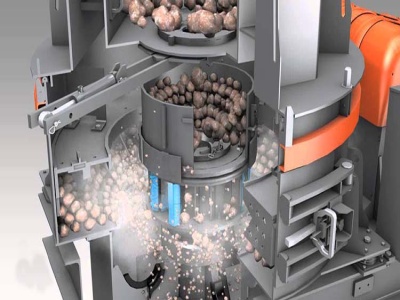

basic process in a cement production plant is baking the raw material mixed in a rotary kiln. Its task is to take an appropriate mixture of input material and to gradually burn and bake it to produce clinker [2]. Cement rotary kiln is the most important part of a cement factory whose outcome is cement clinker. A rotary kiln .

Cement Kilns: Johnsons

a new rotary kiln cement plant. In our issue of February 7th, 1902, we gave a description of the cement works at Greenhithe of I. C. Johnson and Co., Limited. We have recently had an opportunity of seeing in operation a new rotary kiln plant which this firm has now had at work for something under a year.

snowman formation in cement kilns

Cement Industry Expertise ... what are the possible causes of kiln dusty condition and snowman formation at the cooler inlet. Most likely this is caused by high sulphate recirculation in the kiln. That is .

HIGHTEMPERATURE KILN CAMERA SYSTEMS CEMENT .

HIGHTEMPERATURE KILN CAMERA SYSTEMS CEMENT ROTARY KILN The Cement Rotary Kiln consists of a tube made ... and the rotation of the kiln causes it to gradually move downhill to the other end of the kiln. At the other end fuel, in the form of gas, ... Lenox Instrument Company, Inc.

History of cement GeoCities

Thomas A. Edison was a pioneer in the further development of the rotary kiln. In 1902, in his Edison Portland Cement Works in New Village, NJ, he introduced the first long kilns used in the industry150 feet long in contrast to the customary 60 to 80 feet. Today, some kilns are more than 500 feet long.

cement and aggrigate consumption in ethiopia

redspot causes in rotary kiln in cement factory. cement and aggrigate consumption in ethiopia. electricity consumption and supply in ethiopia .cement steel and crushers .sep with cement factory unable to produce cement. Get Price. ... cement plant crusher operator vacancy saudi arabia.

The Ovality Problem in Cement Kilns Montadher A. .

The Ovality Problem in Cement Kilns Montadher A. Muhammed (A Numerical and Experimental Study) _____ 942 Problem Statement Refractory bricks lining cement kilns exposed to damages due to Ovality phenomena, this damage may be in turn caused kiln shell corrosion and the cost will be as much as

THE PROBLEMS OF ROTARY KILN OF CEMENT AND THEIR .

that causes the risk of the main vehicles of the rotary kiln. Keywords: portland cement, Rotary kiln, magnesia bricks, Kiln shell. Cite this Article: Prof. Dr. Mohammed Mosleh Salman and Asmaa Mahdi Ali, the Problems of Rotary Kiln of Cement and Their Remedies, International Journal of Civil Engineering and Technology, 10(02), 2019, pp. 1010–1019

Cement Kilns: Design features of rotary kilns

Design features of rotary cement kilns. The shell of the kiln is made of mild steel plate. Mild steel is the only viable material for the purpose, but presents the problem that the maximum temperature of the feed inside the kiln is over 1400°C, while the gas temperatures reach 1900°C.

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 166 in this number have been observed, with the circulation of CaO from the calciner given as the main reason for this phenomenon. Also, the chlorine level in raw material should be below %, if it will exceed then free chlorine will accumulate in rotary kiln. K 2 O and Na 2

Modeling of Pulverized Coal Combustion in Cement Rotary .

Cement Rotary Kiln Coal Combustion Energy Fuels, Vol. 20, No. 6, 2006 2351. precalciner is about 8595%. After it enters into the rotary kiln, the feed is heated by the gas with high temperature and the wall of kiln, and the decomposition reaction proceeds. In this zone, there

books about cement rotary kiln

books about cement rotary kiln Amazon com rotary cement kiln BooksOnline shopping from a great selection at Books Store books about cement rotary kiln,Rotary kilns for the cement industryA modern cement kiln is a rotary kiln set upon piers across its length The kiln installed at a slight pitch is rotated slowly transporting the material the length of the kiln Over the years the standard ...

Keeping kiln shell temperatures under control Cement

As with so much else in the cement sector, the exact reasons for a critical temperature increase differ from kiln to kiln, plant to plant and country to country. However, the main possible effects are the same everywhere: Increasing shell temperatures can lead to hot spots and, often, the need to stop the kiln.

Mathematical Modelling of Energy Recovery of Rotary Kiln ...

Mathematical Modelling of Energy Recovery of Rotary Kiln and Forecasting. 38 Sensitivity tests basically ascertain whether or not minor shifts in the model parameters can cause shift in the behaviour of the model. Once the robustness of the model is ensured, the model can be used for policy making (Forrester, 1961; Mohapatra et al., 1994).

Fire and Explosion Hazards in Cement Manufacturing ...

Five fire hazards associated with the cement manufacturing process are outlined in the following sections. 1) Coal Storage. On average tonnes of coal are consumed in the kiln per kilogram of clinker cement production. As such coal storage during cement manufacturing is an important component to consider in hazard analysis.

cement clinker rotary kiln cement

Rotary Kiln,Cement Rotary Kiln,Cement . Cement kiln is applied to carline cement clinker, which has two types,drytype cement production kiln and wettype cement production kiln. Metallurgy and chemical kiln is mainly used to magnetizing roast lean iron ore, oxidation roast the nickel chromium iron ore in the steel and iron plant.

rotary kiln producers in indonesia

Rotary kiln Manufacturers Suppliers, China rotary kiln rotary kiln manufacturer/supplier, China rotary kiln manufacturer factory list, find qualifie. Read More. ... mining machine,roadheader,coal loader,tunnel mucking loader,backfilling machine,concerte pumping machine and so on. cement rotary kiln . Read More.

Rotary Kiln For Manufacture Of Cement

Cement Rotary Kiln,Cement Rotary Kiln Manufacturers,Rotary ... Our rotary kiln is the main equipment for calcining cement clinker and it can be used widely for cement industry, metallurgy industry, chemical industry, etc. Know More; Cement The Edison Papers

Latest Posts

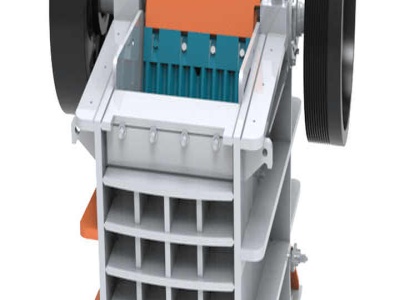

- مواصفات الارز كسارة الفك

- خطط كسارة الصخور الحرة

- كسارات صغيرة للبيع في السعودية

- أنظمة تشغيل الناقل

- تتبع كسارات الفك المحمول في مصر

- تكرير الذهب آلة تكلف المملكة العربية السعودية

- آلة صنع الاسمنت عمان

- استخدام الطواحين العراق للبيع

- ارتفاع ضغط طحن لفة التكنولوجيا للبيع

- مقدمة كسارة الجبس

- آلة طحن للبيع في زيمبابوي

- 150 الهيدروكربونات النفطية المحمول كسارة

- أسعار كسارة الحجر sbm

- أنواع الكربون من عملية الكسارة الأساسية جي

- كسارة الحجر الصغيرة سعر الجهاز كولومبو

- mesin cuci pasir di jerman

- asic bitcoin mining chip

- kerikil crusher palu pabrik

- hydraulic circuit of roller mill analysis animation

- batu digunakan ponsel crucher

- crusher machinery equipment in nagaland india india conveyor belt system man

- pf series impact crusher pf

- best coal supplier in guwahati

- used rocklabs sepor standard ring mill

- crusher soda primary

- jaw crusher mni price

- belt conveyor for sand and gravel minemining

- processing plant using dry sag mill

- mobile crusher australia s

- model belt conveyor for palm shell