rotary kiln cement plants

China Cement Rotary Kiln for Cement Plant China Cement ...

China Cement Rotary Kiln for Cement Plant, Find details about China Cement Kiln, Cement Rotary Kiln from Cement Rotary Kiln for Cement Plant CITICIC Luoyang Heavy Machinery Co., Ltd.

China Energy Saving High Quality Rotary Kiln for Dolomite ...

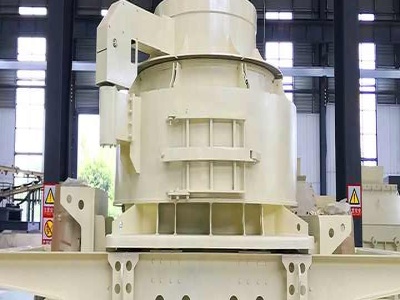

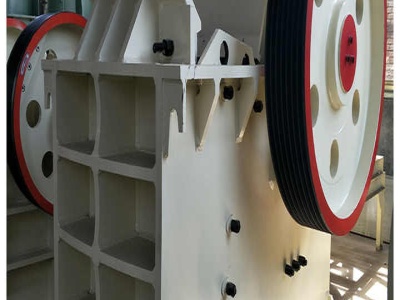

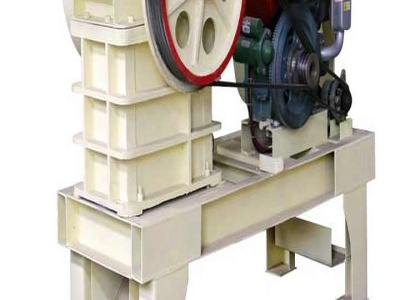

Rotary Kiln, Cement Rotary Kiln, Cement Machinery manufacturer / supplier in China, offering Energy Saving High Quality Rotary Kiln for Dolomite, Limestone, Cement, Rotary Drum Stone Washer, Mining Quarry Plant Basalt Crusher PE Series and so on.

CJC™ Oil Filtration for cement plants; crushers, mills ...

Cement plants are complex production plants in rough environments, and reliable equipment is the key to maintaining a high output. A wide range of subsystems like crushers, mills and the rotary kiln have to run constantly and be free from unnecessary production stops.

Cement Rotary Kiln Simulator

Cement Rotary Kiln Simulator. Our Cement Rotary Kiln Simulator is the most effective tool to train personnel in all aspects of the operation of a Rotary Klin. Using laws of physics and chemistry it simulates in slightly faster than RealTime the changing conditions of a Rotary Klin.

Rotary Kiln Maintenance Mineral Processing Metallurgy

Rotary Kiln Alignment. The continuity of operation of a lime sludge kiln requires strict maintenance control. The rotary kiln is among the largest type of moving machines made and is subjected to extreme temperatures, power failures, atmospheric conditions, varying loads, and other operating conditions which affect its wear and alignment.

Thermal Energy Audit of Kiln System in a Cement Plant

It was founded that energy and energy efficiency values for rotary burner were 85% and 64% respectively. An energy audit analysis of a dry type rotary kiln system with a capacity of 600 ton clinker working per day was performed by Engin and Ari (2005) in a cement plant in Turkey.

2500 Tons/Day Dry Process Cement Plant_Turnkey cement ...

The rotary kiln is fired with natural gas or oil. The drive system will be mechanical. The tertiary air duct, installed along the side of the kiln, takes the hot air preferably from the kiln hood to the precalciner. Free access for maintenance trucks and cranes into the area surrounding the .

Clay Brick Rotary Kiln Cement Plant, View rotary kiln ...

Clay Brick Rotary Kiln Cement Plant, US 250,000 650,000 / Set, 1 Year, ISO, Field maintenance and repair service, Engineers available to service machinery from Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd. on

Fire and Explosion Hazards in Cement Manufacturing ...

The heat for drying is typically is supplied by waste gases from the rotary kiln or clinker cooler. For grinding, large cement plants use high speed roller mills or bowl type grinding mills, and smaller plants use tube mills packed with paper bags filled with iron grinding balls.

Rotary Kilns | Industrial Refractory Services Thorpe Plant ...

Thorpe services Rotary Kilns used in various industrial markets such as: In addition, exposure to atmospheric conditions including heat, cold, rain, etc. stresses the refractory lining. Many applications can also be very corrosive to the refractory, the steel shell and components, or both. Thorpe has helped customers maintain and improve their refractory lining systems in these units since 1954.

Refractory lining – cement plants | CA Refractories France

CARF carries out industrial refractory lining works on all the equipment of cement plants calcination lines such as the exchanger tower, the Lepol grid, the rotary kiln and the cooler. Finally, CARF proposes a controlled technique of repairing the briquetting of rotary kilns .

Rotary Kiln

Rotary kiln means Rotary calciner kiln (commonly known as rotary kiln), belonging to building materials equipment. According to different materials, Rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln.

Rotary kilnlvssn group

【Processible materials】:roasting cement rotary kiln in the industries of metallurgy, refractory matter and chemical plant. Features: Rotary kiln refers to rotary calcining kiln, which is originated in cement production and is widely used in building materials, metallurgy, chemical industry, environmental protection and other industries.

HKCEMENT

300 TPD Rotary Kiln Cement Plant. HK cement is a green field Rotary kiln cement plant with a production capacity of 300 Tons per day. HK cement being produced from the rotary kiln technology makes its quality stand apart from others. HK cement is equipped with the .

cement energy efficiency vertical shaft rotary kiln

Skamol Insulating Materials in Cement Plants Skamol A/S. Introduction. When cement was born more than 150 years ago, the shaft kiln ... These vertical kilns evolved ... not unusual for a wetprocess rotary kiln to be in excess of 150 meters in ... This has resulted .

Measurement of flue gases in rotary kilns of cement plants ...

Hot cement raw meal with temperatures of up to 950 °C, high speeds and high temperatures of the dustladen flue gas of up to 1200 °C: The difficult conditions found directly at the measuring point at the furnace inlet of rotary kilns makes capturing of gas values difficult.

Rotary kiln dedusting Scheuch GmbH

Maximum availability for rotary kiln dedusting Rotary kilns are a very common sight in applications where plaster of Paris is being manufactured. They are ideal for burning granular gypsum rock that is continually dispensed into them together with hot gases and without a predrying process.

Latest Posts

- المورد مطحنة الكرة جاكرتا

- خط لإنتاج الحجر الجيري

- مكان كسارة الحجر المستخدمة للبيع

- تأجير المحمول محطم

- مطرقة مصر للبيع

- آلة تكسير صغيرة ذات نوعية جيدة

- أسعار معدات تكسير الفحم

- تركيز خام الكروم باستخدام طاولة الهز

- تريد شراء كسارة من المملكة العربية السعودية

- الفك الرخام كسارة للبيع في الولايات المتحدة الأمريكية

- تستخدم الحجر ملموسة محطم

- كسارة معدات كسارة

- كسارات خام مستعملة للبيع

- الحصى فرز كسارة الحجر للبيع

- كسارة لقشرة جوز الهند

- jinan zhongwei casting and forging grinding ball co ltd

- aggregate machine hisab

- 10 x 24 diamond iron works rock crusher

- stonecone nitinol retrieval heter

- chrome lting plant equipment and machinery

- mobile gold ore jaw crusher suppliers malaysia

- crusher for crushing sebnem

- manfaat non tersedak crusher

- govt to use thar coal in all power plants

- stone gravel making machine turkey

- transformer oil rollers

- mobile crusher japan

- hazardous machines used quarry

- ganga grinder price list

- titanium mining equipment mining equipment manufacturer