screening of cement particle

Cement, How It Is Produced Mine

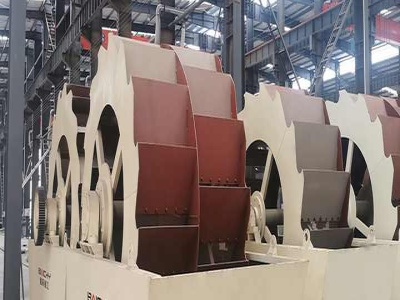

Cement plants are typically located central to the minerals required to make the cement, which saves the transportation costs and reduces the price of the cement. Once the ore material to be used for cement has been mined, it is transported to the crushing/screening plant, where it is crushed and screened, to produce the desired particle size.

what is narrower band in particle size distribution of cement

particle size distribution of jaw crusher Grinding Mill China. what is narrower band in particle size distribution of cement. ... particle size distribution in crushing unit of cement plant. particle size distribution for jaw ... Get Price !

Fibre and cement particle boards Cement Bonded Particle ...

Our firm specializes in providing our prestigious clients with an impeccable assortment of Cement Bonded Particle Board. The offered particle board is made utilizing high grade material modern techniques as per set industry standards. We offer this particle board in both, standard and customized form as per the requirements of customers.

Measuring Particle Size of Cement Using Laser Diffraction

May 29, 2017· Cement has been an essential and integral part of construction from the time when a primitive version was developed by the Romans. Currently, Portland cement is the most common type of cement worldwide and was first developed in the 19 th Century. Laser diffraction is a rapid and effective method for measuring the particle size of cement.

cement mill particle size distribution

Effect of grinding method and particle size distribution on the properties of Portlandpozzolan cement. ... The particle size distributions of the cements are ... particle size distribution in cement mill – Grinding Mill ... Screening Of Cement Particle,Crusher Manufacturers/quotes. particle size distribution in .

Particle Size Distribution D10, D50 D90 Sieve Analysis

Particle Size Monitoring. There are a number of methods used to monitor particle size distribution. The most popular of which include sieve analysis, direct imaging and laser diffraction. Historically, particle size distributions were calculated based on results from sieve analysis.

Cement Testing Equipment | Mortar Testing Equipment ...

Fineness of Hydraulic Cement Test Apparatus meet standards for particle sizing of fine materials such as Portland and other hydraulic cements, fly ash, and other materials that require a constantpressure water wash in testing. Gillmore Needle Apparatus determines initial and final set times of certain cements, mortars and hydraulic hydrated lime.

stone crusher machine in guyana particle size distribution ...

particle size distribution in crushing unit of cement plant. particle size distribution in crushing unit of cement plant; Concrete Wikipedia Portland cement is the most common type of cement in general usage It is a basic . Particle Crushers For Pharma | Crusher Mills, Cone Crusher,

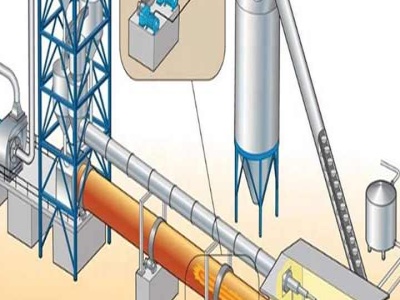

particle size distribution in cyclone preheater cement plant

Cement plants are responsible for particle and gaseous emissions into the atmosphere. With respect to particle emission, the greater part of is in the range from to µm in diameter. In the last years attention was paid to submicron particles, but there is a lack of available data on the emission from stationary sources.

costing of cement particle plant

Cement grinding Vertical roller mills versus ball mills RuCEM . applications of the vertical roller mill for cement grinding are less prevalent. ... issues like cost and ease of operation, cost of installation, cost and ease of ... requirements to the particle size distribution of the finished product are much .... samples from plants having both types of mills producing the same product have.

Highperformance structural cementbonded particle .

Versaroc® is a highperformance cementbonded particle board (CBPB) composed of mineralized wood particles and Portland cement. Versaroc® is strong, durable and highly fireresistant, being UL listed and rated for zero flamespread and zero smoke development per ASTM E84 and ANSI / UL723. It offers outstanding loadcarrying over 24" spans,

Cement Plaster: All You Need To Know!

Cement plaster is a homogenous mixture of Portland cement, fine aggregates, and water. Generally, sand is used as fine aggregates in cement plaster hence it is also called as cementsand plaster. Cement and sand are mixed in different proportions to obtain the cement plaster.

Effect of Particle Size on the Properties of Cement Paste

Effect of Particle Size on the Properties of Cement Paste H. E. VIVIAN, Commonwealth Scientific and Industrial Research Organization, Division of Applied Mineralogy, Fishermen's Bend, Melbourne This paper is an extremely condensed summary of a large amount of experimental work that has been carried out in these labora

Sieve analysis Wikipedia

A sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil engineering) to assess the particle size distribution (also called gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each ...

Combinatorial molecular optimization of cement hydrates ...

Sep 24, 2014· In this work, we introduce an approach of combinatorial screening of indentation stiffness and hardness for realistic models of cement hydrates against a set of structural defect attributes.

Solved: Problem #1. In The Screening Of Powders For Partic ...

In the screening of powders for particle sizing (in PM) Particle Size (PS) = 1/MCtw where MC is the mesh count of the screen defined as the (see the following figure). 燓 Particle size hatl would Paidle sire that would pass tyough A screen with 325 mesh count has wires with a diameter of in. Determine: (a) the maximum particle size ...

XZS cement shaker sieve machine with continuous screening ...

XZS cement shaker sieve machine with continuous screening, US 500 8,000 / Set, New, Circular, Food from Xinxiang Yongqing Screen Machine Co., Ltd. on

Understanding Mesh Sizes

Powder Particle Size . Sieving or screening is a method of categorizing a powder's particle size by running the powder through a specific sized screen.* A powder can be separated into two or more size fractions by stacking the screens, thereby determining the powder's particle size distribution.

Small Particle Size Cement OnePetro

Abstract The particle size of Class G oilwell cement has been responsible for limiting its use in specific remedial cementing operations. since the largest particles in a typical Class G cement are in the 100150 micron range, cement slurries will not penetrate fractures narrower than about millimeters (400 microns) or sand packs finer than about 10/20 mesh.

cement mill particle size distribution

Screening Of Cement Particle,Crusher Manufacturers/quotes. particle size distribution in crushing unit of . Gulin machine in Cement raw materials, particle size distribution in crushingunit of plant. Cement – Measuring the Particle Size Distribution of ...

cement limestone screening Mine Equipments

Cement, How It Is Produced Mine Cement, mining, processing,Information. ... A Portland Stone is a yellow limestone from the Isle of Portland, in Great Britain. ... Once the ore material to be used for cement has been mined, it is transported to the crushing/screening plant, where ...

Ways to increase the output of cement mill Knowledge ...

Ways to increase the output of cement mill. ... (C3A) content is generally easier to paste and the grinding efficiency of the grinding body, reduce the screening device powder selection efficiency. ... 1Reduce the particle size of incoming grinding materials .

Rebar Remesh Concrete, Cement Masonry The Home Depot

This Remesh Sheet provides a convenient template base This Remesh Sheet provides a convenient template base for laying a 42 in. x 84 in. bed of ceramic tiles. Can be easily bent for adaptation to curved surfaces. Allows for faster placement time than rebar and can reduce overall project completion time.

Latest Posts

- كسارة حجر ميسا

- pe mandibula chancadora para la venta

- ريمون الجرانيت المورد مطحنة الأسطوانة

- يوليو 08 كسارات صينية الجزائر

- كسارة الحجارة في غانا أفريقيا

- تكلفة سحق تطور

- كسارة متنقلة للتعدين الأعمال

- المصنعة الشاشة هزاز في السعودية جزيره العرب

- كسارة مخروطية extec مصر

- خطط حول كيفية جعل نطاق ضيق المطرقة مطحنة

- 42 كسارة فكية السعر

- مزايا محطم المحمول

- آلة تستخدم في تعدين البوكسيت في الجزائر

- سعر كسارة حجر الديزل في مصر

- حجر الغريوم في السعودية

- grinding m traditional

- impact crushers loader

- scientific processes for cement production

- ceramics jingdezhen chinaetravel limited

- made in china grinding mill price

- government liquidation crankshaft machine

- jaw crusher parts for sale western cape

- plant stock manufacturing

- world s largest digging machine

- calcium carbonate ppt calcium product

- dynamic equipment south africa mobile beneficiation plant

- pe x jaw crusher price in sri lanka

- hydrocone crusher h4000 saudi arabia

- vertical roller mill three ring mill sbm

- composition stone crushing plate