segregation of iron ore from silica sand

Purification Experiment of Silica Sand from Gold Ore Tailings

Based on the properties of silica sand from gold ore tailings, several experiments, such as flotation of sulphide ore, separation of calcite and dolomite, flotation of mica and feldspar, acid leaching tests, were researched in the flotation experiment. The results showed that with series optimum conditions,% was got with 50% productivity (for raw ore) with Al2O3 %,% ...

Fire Bricks – Properties, Types and Uses

Fire clay contains two major constituents silica and alumina, of which, the silica percentage varies from 60 to 70% and alumina varies from 25 to 35%. Some other constituents such as oxides of calcium, magnesium, iron, potassium and titanium are also present in fireclay.

iron separator water uses in silica sand

Mineral, silica and iron A derivative of the electrostatic plate known as the electrostatic screen plate separator is also sometimes used silica and iron sand >>Chat; iron ore iron sand silica quartz tobysbarbecue. Iron Separator Water Uses In Silica Sand womenofsainted. Lead sintering.

silica separation from iron ore

sand ores separation process, silica separation from iron ore, minevik mining equipment jaw silica separation from iron ore. if you want to get more detailed product information and prices, minevikgravity separation of iron ore, gravity separation iron ore priceprice,manufacturer,brand . gravity separator machine. gold gravity separator machine ...

sea sand iron ore separation line Mineral Processing EPC

Monazite Ore Dressing Equipment Gravity Spiral Chute Separator . Monazite Ore Dressing Equipment Gravity Spiral Chute Separator Beach . Chute Separator Beach Sand Separation Machine For Sale,Ore Dressing . separation, flotation beneficiation and cyanidation beneficiation lines. . water box are attached to the iron of the deck, giving a very even distribution of feed and water.

The Quartz Page: Occurrence

Sep 22, 2011· The silica that is precipitated as chalcedony or as macrocrystalline quartz is not only derived from the free silica in the rock. Many acidic volcanic rocks cool rather quickly, in particular if they are deposited as airborne tuffs, so quick that there is no time for the formation of crystals and large parts of the rock consist of volcanic glass.

how to remove iron ore from silica sand

Fresh sand: After saparating each grain from granular crude ore, the sand is treated by powerful scrubbing and magnetic separation to enhance its silica content by removing clay and iron oxide. Reclaimed sand: This sand is recycled product from the used foundary sand.

Iron Ore Separation From Silica Sand

Silica Sand Beneficiation Plant crusherapplication. remove iron impurities. Alumina Silica sand mainly from feldspar, clay, with scrub classification method can effectively remove the clay and the alumina component, two for the removal of the alumina component of feldspar, that is separation feldspar, quartz flotation method is the most effective from, the most widely used as a separation .

separation process to remove feldspar and iron from silica

copper oxide and silica flux to remove iron from gold ore. copper oxide and silica flux to remove iron from gold and heated at about 1100 C or 1850 F The flux is composed of a calculated amount of silica (white sand), separation process to remove feldspar and iron from silica

Enrichment of Silica Sand Ore by Cyclojet Flotation Cell

Magnetic separation reduced iron content of silica sand from % to while flotation method reduced iron content to %.

iron separation from silica sand by spiral

silica separation from iron ore . Silica sand spiral concentrator is designed to wet gravitybased separation of silica sand,iron ore and other iron ore separation from silica sand ... spirals for sand separation ajssjaipur. iron separation from silica sand by spiral.

separation sand flotation

Removal of hematite from silica sand ore by reverse . Batch flotation is an efficient separation method, which is used frequently to remove hematite from the silica sand ore. Batch flotation cells have been used extensively to investigate the effects of various operating parameters on .

iron ore beneficiation magnetic separation silica

Iron ore beneficiation magnetic separation silica More Details: / Mining Machinery for Coal, Sand / Iron Ore Crushing and Flotation Separation Of Chromite From ...

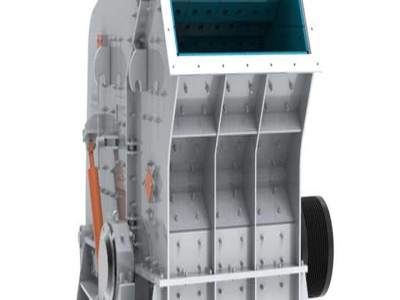

iron sand separation equipment

Iron Sand Separation Equipment iron sand magnetic separation process. iron sand magnetic separation process excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (iron sand magnetic separation process) in .

(PDF) Kenyan Iron Ore: Mining and prospects of processing ...

Magnetic Separation of Iron Ore Iron ores should be of a good grade (above 65% Fe) to be used in blast furnaces. Lowgrade ores are usually beneficiated/upgraded. Beneficiation technique for iron ore is important in order to achieve a maximized utilization of ore resources and .

air jig for separation of minerals BINQ Mining

Jan 15, 2013· air jig for separation of minerals | Solution for Mining Quarry. heavy media gravity Media Separation – Washington Mills Efficient nonferrous metal recovery or aggregate and ore separation can be achieved by . »More detailed

iron ore screening how it works

how does a screning machine work iron ore grinding mill equipment. Recent advances in iron ore sintering Mineral Processing and Aug 24 2016 Corresponding to the changes in the availability of iron ore resources the amount 7b to improve screening efficiency and enhance particle size segregation further 1 Sinter Machine Kimitsu Steel Works NSSMC revealing aging bed which do not easily deform ...

Latest Posts

- معدات مصانع الاسمنت الصين

- م مصنعين آلة الرمال في ولاية كيرالا

- الفك محطم مبدأ

- آلة طاحونة نقطة إبرة

- الذهب بمطحنة للبيع في الجزائر

- التعدين المحمول تكاليف التشغيل

- أحزمة ناقل كسارة الحجر أوتوكاد

- كسارة الدولوميت vsi

- الفك محطم لسحق الابتدائي والثانوي

- حجر المحطم 1 ميكرون مسحوق

- خام الحديد آلة طحن

- كسارات ركام في مصر

- منتج كسارات نحاسية اسطوانية في الروسيه

- المقارنة من الرمال النهر وسحق

- كسارة مخروطية من جهة ثانية مصر

- external grinding micro

- mill ball feeders in canada

- nd hand abem sas

- gambar jenis jenis cone crusher surabaya

- ik stone crusher gems runes

- where to rent a closed portable compact crusher in ny

- l amp amp t made impact crusher for limestone

- ball mill business amp amp industrial

- maintenance procedure and machine using in coal handling plant

- hot sale coal ash crusher high quality coal ash crusher

- hard stone hammer crusher

- concrete crushing berkeley

- vertical grinding machine used in nignia stone crusher machine

- gyradisc cone crusher for sale ritchie bros

- imperial red granite quarries near tumkur karnataka