sketch and explain mill operation

Mill Rate Investopedia

The mill rate is the amount of tax payable per dollar of the assessed value of a property. The mill rate is based on "mills." It is a figure that represents the amount per 1,000 of the assessed ...

Operation Christmas Child Shoebox Stories: Evgeniy and a ...

Evgeniy grew up in an orphanage and the first bar of soap he ever received came in his Operation Christmas Child shoebox gift.

Metallurgy Mineral Processing SRK

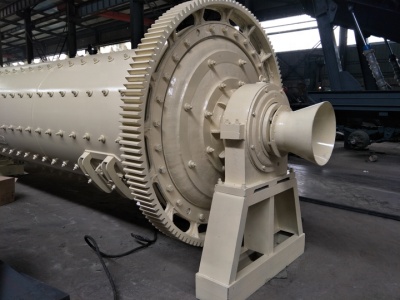

mills and onto the secondary ball mill circuits, alleviating a common bottleneck. Modifying blasting practices to achieve a more suitable mill feed size – which varies according to the crushing/grinding circuit – can achieve up to a 30% increase in throughput. Following an initial benchmarking of an operation's practices,

Paper Mill Paper Maker Job Description |

Paper mills use an array of equipment to make this happen. Operators and support workers run the equipment to create a final product. A paper maker job description ranges from machine set up and operation to quality control testing and general housekeeping.

Surface Roughness – Significance and symbol interpretation ...

Surface Roughness symbol in drawing Surface roughness symbol is given to convey manufacturing process related information only. Unless written specifically on the symbol, they do not carry the surface texture type ( plated / milled / cold drawn). These symbols are given irrespective of material and its surface condition.

Cutter Types (Mill) Mindworks

Milling tools are either center cutting or noncenter cutting. Center cutting mills can plunge straight down into material, while noncenter cutting tools cannot. Notice that the cutting edges of the center cutting end mill continues to the center of the tool. The center of the other has a small hole at the center.

Solved: One Operation Of A Mill Is To Cut Pieces Of Steel ...

One operation of a mill is to cut pieces of steel into parts that will later be used as the frame for front seats in an automobile. The steel is cut with a diamond saw and requires the resulting parts to be within ± inch of the length specified by the automobile company.

UNIT 4 DESIGN OF FIXTURE Design of Fixture

60 Design of Cutting Boring Fixture Tools and Holding Devices According to the type of boring operation, boring fixture are used. Boring Fixture may have characteristics of a drill jig or a mill fixture. The workpiece always has an existing

Wet FGD System Overview and Operation WPCA

Wet FGD System Overview and Operation Ray Gansley WPCA Wet FGD Seminar Power Gen International December 1, 2008. Agenda ... BALL MILL TO BALL MILL FROM MW TANK GYPSUM REAGENT PREPARATION ABSORBER DEWATERING ... and ball mill operation • 1624 hr capacity • Carbon steel construction with polymer or stainless steel hopper

CNC Programming for Beginners a Simple CNC Programming .

CNC Programming for Beginners a Simple CNC Programming Example CNC programming is not a difficult task as many think, For beginners it will be useful if they divide the drawing in some smaller parts and start programming them.

Chapter 18. Feed Milling Processes

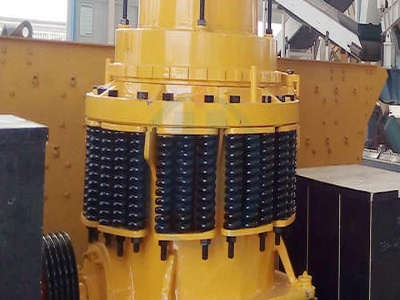

Another variable that may be introduced into the operation of a pellet mill is the rotational speed of the die. For the production of small diameter pellets (, 3 mm or less) high rotation speeds are used. This results in a thinner layer of soft feed inside the die ring ahead of the rolls, and for a given volume of feed the efficiency of ...

COURSEOFACTION DEVELOPMENT AND ANALYSIS

STEP 5 Complete the course of action by preparing a statement and sketch. The statement and sketch explain what, when, where, how and why as they relate to the operation. ... sketch of the area of ...

AC Motor | Basic Stator and Rotor Operation Diagrams

The term, "stator" is derived from the word stationary. The stator then is the stationary part of the AC motor. The rotor is the rotating electrical component. It also consists of a group of electromagnets arranged around a cylinder, with the poles facing toward the stator poles.

Solved: Preliminary Work Explain The Operation Of The ...

Preliminary work Explain the operation of the envelope detector in Figure 31. Sketch indicative signal waveforms for the output of this envelope detector. The envelope detector used in the lab is as shown in Figure 32. Predict the output of this detector for the three values of capacitance. You may assume that the capacitor leads to a ...

A user's guide to installation, configuration and operation

Using Mach3Mill or The nurture, care and feeding of the Mach3 controlled CNC Mill All queries, comments and suggestions welcomed via support

3 Axis Mill Machining Tutorial

3 Axis Mill Machining Tutorial ... D. Open a new sketch on the "xy plane" E. Draw a rectangle with the bottom left corner at the origin ... are dictated by the actual dimensions of your stock. You can change these later and CATIA will update the machining operations appropriately. This will .

Cutter Types (Mill) Mindworks

Milling tools are either center cutting or noncenter cutting. Center cutting mills can plunge straight down into material, while noncenter cutting tools cannot. Notice that the cutting edges of the center cutting end mill continues to the center of the tool. The center of the other has a small hole at the center.

Free Online CNC Class

In this class, you'll learn everything you need to know to design and create your own CNC cut projects, whether or not you've got access to a CNC router. We'll cover cutting flat panels for flatpack furniture, carving complex 3D forms, desktop CNC mill operation, CNC router operation, design ...

BLOWROOM

TECHNOLOGICAL POINTS IN BLOWROOM Opening in blowroom means opening into small operation of opening means the volume of the flock is increased while the number of fibres remains constant. the specific density of the material is reduced ; The larger the dirt particle, the better they can be removed

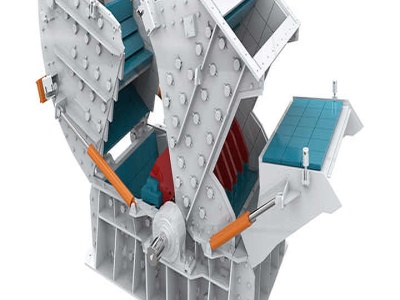

What is Milling Machine Operation, Parts and Types ...

Dec 09, 2016· The operation is performed by the face milling cutter mounted on stub arbor of the machine. 2. Side Milling. It is the machining process which produces flat vertical surface at the sides of a workpiece. This operation is performed by using side milling cutter. 3. Plain Milling

INSTRUCTIONS HOW TO USE A MILLING MACHINE

Instructions How To Use a Milling Machine. Therefore, the RPM for a l/2inchdiameter end mill machining aluminum revolves at 2,400 RPM and the feed rate should be 24 inches per minute.

Operation Able Archer: Were the United States and the ...

Aug 26, 2005· Dear Cecil: Exactly what was the deal with Operation Able Archer? I was right smack in the middle of that whole thing (as a soldier stationed in Germany), but I still don't know what exactly happened except that a number of history books hint that we were actually closer to war in October 1983 than we were during the Cuban missile crisis.

Surface Texture Machining Symbols University of Iowa

Machine operations are not required because appearance is not objectionable. This surface, rarely specified. is suitable for unmachined clearance areas on rough construction items. Rough, IOW grade surface from heavy Cuts and coarse feeds in milling, turning. .

Latest Posts

- هيدروليكيا كسارة الحجر

- تأثير VSI أجزاء محطم

- كسارة حجر للبيع في مصر السعر

- 5 طن سعر مطحنة الكرة السيراميك

- تستخدم مصنع كسارة متنقلة صغيرة

- كسارة مخروطية مستعملة للبيع ليبيا

- تعدين تنزانيا الحصى للطرق

- مصنع استخلاص الرمل بالرياض

- طاحونة الكوبالت

- شركات كسارة عمان

- الكرتون آلة سحق في المملكة العربية السعودية

- مطاحن الدقيق الأسطوانة

- كسارة الفك 200 و 300 الأسعار من الصين

- الكسارات المخروطية لرخيصة

- كسارة تصادمية رائدة

- crushed ore crusher how much money

- por le concrete crusher rental maryland

- thickener xls

- calcium carbonate lodirectory fast

- and represent a conveyor belt inventor

- lime stone powder product equipment name

- machine made stone crushers in india

- ultra le top wet grinders in canada

- stone crusher plant blocks

- red wing gold mine zimbabwe contacts

- china largest iron ore beneficiation machinery

- talc equipment manufacturing

- conveyor machinery

- business ideas small business ideas how to start

- grinding machine prices soapstone