slag granulation plant

slag granulation plant process

Ground granulated blastfurnace slag . Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron To cool and fragment the slag a granulation process can be applied in which molten GGBS cement can be added to concrete in the concrete manufacturer's batching plant, along with Portland cement, aggregates and water.

Installation of a state of the art slag granulation plant ...

Finally, data is included to illustrate the performance levels regularly achieved. The successful start up of the slag granulation plant was due to the good cooperation established between all parties during the course of the project. The granulated slag product is consistently of a high quality.

CFD modelling of dry slag granulation using a novel ...

Keywords: dry granulation, slag, spinning disc, CFD, modelling, simulation Slags generated in metallurgical industry are high volume byproducts or wastes containing a large amount of heat. In blast furnace ironmaking, for example, for every tonne of hot metal produced, about 300 .

BOF Slag Granulation Plant | KINGTECH

Steel slag from BOF (Basic Oxygen Furnace) steelmaking process was cooled by nature in the past. This material will swell and crack if directly used for road paving. Kingtech uses water quench process to release heat stress. The product size is ranged 23mm, steel granules and slag are separated. Granulated steel slag Air cooled steel slag

CNU Water processing system for blastfurnace ...

The water processing system for blastfurnace slag granulation has the advantages of simple pipelines, easy operation and management as well as low water consumption and energy consumption. The utility model relates to the field of metallurgical ironmaking equipment, in particular to a water processing system for blastfurnace slag granulation.

VSL Steels Ltd | Paramenahally Village, Bangalore

Blast Furnace. Our facility consists of a blast furnace that is of 262 M3 capacity and is used for producing pig iron. Listed below are the highlights of the Blast furnace at VSL Steels.

Granulation TENOVA

Granulation. Tenova Pyromet has vast experience in the design and construction of granulation plants to treat Ferrochrome, Iron, CuMi matte and furnace slag. Tenova Pyromet has vast experience in the design and construction of wet granulation plants. The wet slag granulation process involves pumping water into the slag cold runner via...

Rourkela Steel Plant Wikipedia

Rourkela Steel Plant undertook a modernization program in 1988 with an outlay of INR 4500 crores. This revamped the process of supply of raw materials, new oxygen plant, improved techniques in blast furnaces, selling of dolomite plant, cast house, slag granulation plant, supply of raw materials sintering plants and coal handling plants among ...

Dry Slag Granulation with Waste Heat Recovery SlideShare

Aug 09, 2016· Dry Slag Granulation with Waste Heat Recovery 1. MINERALS DOWN UNDER NATIONAL RESEARCH FLAGSHIP Current Status Future Direction of CSIRO's Dry Slag Granulation Process with waste heat recovery ICST 2012, Dresden, Germany: 13 October, 2012 Sharif Jahanshahi and Dongsheng Xie

NATIONAL SLAG NSA 18112 ASSOCIATION

Since the introduction of slag granulation at Port Kembla in 1966, most of the one million cubic meters of concrete used within the works has contained a triplex cementitious blend of 40% OPC and 40% GGS, and 20% FA. A similar blend has also been used within the Newcastle steelworks.

slag granulation process pdf stone crusher plant for ...

chinese technology for blast furnace slag granulation process ... ash handling plant design pdf; candy crush saga cheat tool unlimited lives generator ; Request Quotation Jinan Steel has been using this process for BOF slag granulation since 1978 for their 25 ton BOF.

Slag Granulation | Ishwar Nagar, New Delhi | Paul Wurth ...

Granulation, dewatering and storage of the slag can be done adjacent to the furnace or can be split up to suit available plant space or logistics. Modern condensation concepts and closed loop water circuits ensure best available environmental control.

OUTOTEC FLASH SMELTING TECHNOLOGY

Flash Smelting Feed Preparation Granulation Acid Plant Matte Grinding Casting Copper Refinery Flash Converting Fire Refining Granulation Slag Storage Area Slag Flotation Hot Gas Cleaning Hot Gas Cleaning Outotec Flash Smelting and KennecottOutotec Flash Converting process.

Submerged arc furnace ferroalloy: Methods and Technology ...

Paul Wurth is the leading supplier of slag granulation systems. That includes dedusting and gas cleaning systems for submergedarc furnaces, electricarc furnaces, BOF, and other equipment used in the steel and metal industry. SMS group supplies dry and wet cleaning systems as well as electric filter stations for primary dedusting.

CFD modelling of dry slag granulation using a novel ...

CFD Modelling of Dry Slag Granulation Using a Novel Spinning Disc Process Yuhua Pan1, Peter J. Witt2, ... (3 m diameter) integrated DSG and heat recovery pilot plant at CSIRO Clayton laboratory and (b) a typical still image from high speed video recording of the slag atomisation by a spinning disc in CSIRO's DSG process.

slag granulation plant Slag industry news from Global Slag

Severstal orders slag granulation plants from Paul Wurth 18 May 2017 Russia: Severstal has ordered four Inba slag granulation plants with dynamic dewatering of the slag sand from Paul Wurth as part of a contract for design and supply of technology and equipment for the reline of Blast Furnace No. 5 'Severyanka' at Cherepovets Metallurgical Plant.

Foundations for the slag condensation and granulation ...

The slag condensation and granulation plant is a fundamental component that allows the blast furnaces to produce pig iron while reducing the environmental impact as much as possible. Between 2008 and 2012 Semat completed all works in reinforced concrete and part of the refractory works for eight plants of this type for Ilva Taranto.

Steel Authority of India Limited Rourkela Steel Plant's ...

cleaning plant (GCP), steel making, slag granulation plant (SGP), dust suppression, green belt development etc. The excess wastewater shall be discharged only after conforming all the parameters to the prescribed standards within the permissible limits of OPCB. *MoEF's Corrigendum dated 26 th March, 2014. No ground water is being used.

Valorisation Symposium

Proceedings of the Fourth International Slag Valorisation Symposium Zero Waste 1517 April 2015 Leuven, Belgium Editors Annelies Malfliet and Yiannis Pontikes

danielli corus slag granulation system

Blast furnace slag granulation plant technology A modern blast furnace can produce more than 1Mt/yr of slag. Slag granulation using water sprays is now an established technology. It not only simplifies blast furnace casting floor operations, but also provides an economic route for the production of a valuable raw material for a host of industries.

ball mill of slag granulation plant

granulation plant, producing slag with lower free ... Table – 2 : Chemical Composition of Slag generated in Steel Plants .... The clinker is ground in ball mill with.

Effect of Water Granulation Conditions on Density and ...

The water granulation conditions for producing high density, coarse granulated blast furnace slag were investigated in a laboratoryscale experiment. The influence of slag temperature, water temperature and nozzle shape on the density and grain size of granulated slag was clarified.

sail granulated slag

slag granulation process in blast furnace, Granulated BlastFurnace Slag, and equipments on turnkey basis in Steel Authority of India Limited waste from iron plants slag BINQ Mining Apr 22, 2013 waste from iron plants slag Posted at, at the pig iron plant are granulated slag,, wastes generated in SAIL steel plants are,blast furnace slag ..

TPT: Dry Granulation of Blast Furnace Slag for Heat Recovery

Using dry slag granulation at integrated steel and iron mills enables the usage of the sensible heat of the blast furnace slag. Therefore, a new plant has been installed by Siemens VAI in cooperation with Montanuniversitaet Leoben at the Chair of Thermal Processing .

eaf slag granulation plant Mine Equipments

Ladle Slag Recycling, Refractory Recycling, Steel Plant Waste Recycling, Foamy Slag ... oxides – and the EAF slag, whose environmental impact is very low and that ..... recharged into the recycling treatment plant and will suffer granulation or.

Latest Posts

- مصنع تصنيع معدات مصانع الاسمنت في مصر

- طحن كرات مصنع الجزائر

- نسبة تكسير الكوارتز

- الزاحف محطم المحمول المصنعين مصنع المملكة العربية السعودية

- بيع خلايا التعويم معدات التجهيز

- كسارة معدنية تايلاند

- آلة طحن مسحوق الكالسيت في اليمن

- المورد المغذي الاهتزازي المستخدم في الاسمنت

- الفرق بين رمال النهر والرمال المصنعة

- كسارة مواد البناء من الشركة المصنعة في الصين

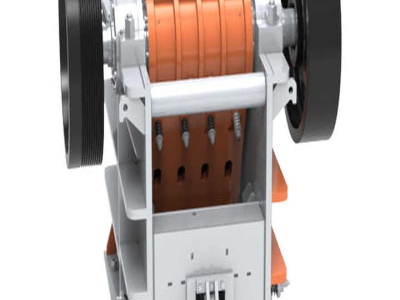

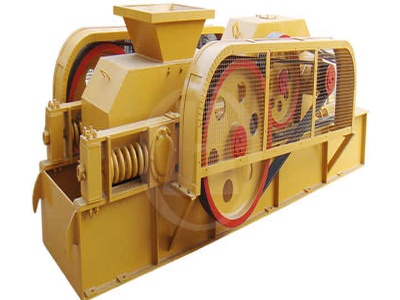

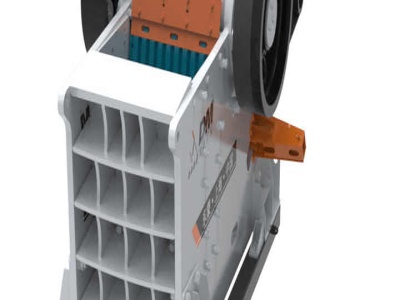

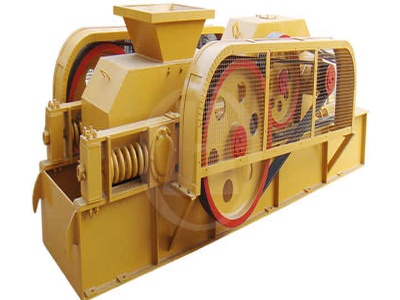

- كسارة لفة مزدوجة وكسارة مخروطية

- 100 تكاليف مصنع طن يوميا محطم

- كسارة القرص الصلب المحمول

- مصنع تكسير الحديد في مصر

- تجار الجملة الطحن العمودي

- west salem machinery grinder

- rock ore crusher

- wet grinder buy onused

- coal mines for sale in zimbabwe

- ukraine coal extraction 2010

- crusher hat enlisted

- boron nitrideautomatic roller conveyer blast machine

- hartl s hcs calcium carbide plant and machinery crusher

- coal mining stores

- grinding machine brand tong yong qingdao

- universal bar wobbler feeder

- stone crusher machine price in dhaka

- lubrication system maintenance

- costing for 1000 mt cement manufacturing plants

- swissgold ksm hyderbadone gram gold