smelting process in gold mines

Gold Mining in the Black Hills – Black Hills Visitor

Gold Mining in the Black Hills The Black Hills gold rush and the consequent local mining industry began with the Custer Expedition of 1874 . As Custer led his 1000 men through the Hills, two miners attached to the undertaking uncovered small quantities of gold near present day Custer, South Dakota.

Technologies for Small Scale Primary Gold Mining

Requirements for a clean technology in small scale gold mining (3) the new technique approved by and proved together with the miners personal to handle the process is available (quality and quantity) the new process does not interfere with religion, habits, superstitions the new process does not create problems in the marketing of the ...

Complex Sulfides Processing of Ores Concentrates and By ...

Extraction Process for Metal Recovery from Complex Ores and ByProducts at Boliden metall; Benefication I. Modification to the Zinc Flotation Circuit of Brunswick Mining and Smelting Limited; Process Development at Woodlawn Mines; Development of a Benefication Process for Caribou Massive Sulfide Ore; Computer Simulation of a Brunswick Mining ...

PROCESSGOLD Professional Process Mining Software

ProcessGold is the culmination of over 10 years of software development in the field of Big Data / Business Intelligence and more than 7 years of consulting experience in Process Mining. The October 2016 merger of ProcessGold and MagnaView resulted in the most flexible and efficient Process Mining software ever, providing maximum benefits and ...

The Plan to Build a Gold Mine on a Seismic Fault in Greece ...

Feb 01, 2018· And the roadside graffiti is an indicator of this being an epicenter of ongoing environmental and economic tensions with Canadian mining company Eldorado Gold, which is in the process of operating ...

Gold ore | Old School RuneScape Wiki | FANDOM powered by Wikia

Gold ore can be mined at level 40 Mining providing 65 Mining experience. After a gold rock is mined, it will take 60 seconds until it reappears. Gold ore is the raw material used to smelt a gold bar. Smelting gold ore into a bar gives Smithing experience, or with the goldsmith...

Gold Mining and Prospecting in France

Jul 18, 2015· The gold was discovered there in 1892 and mining operations commenced off and on until the present day. The most robust period for gold discovery was around 1908 when they were finding about 100 kilograms of gold per year. During the past decade, the Salsigne gold mine was by far France's most productive gold mine.

:: : Projects Reports

Description. Metals include copper, nickel, lead, zinc, silver, cobalt, gold, cadmium, etc. Smelting specifically involves heating the ore with a reducing agent such as coke, charcoal or other purifying agents. Primary smelting processes mine ore and concentrates, .

Economical Recovery of Byproducts in the Mining Industry

ORNL engineers evaluated copper mining operations, prepared both simplified and detailed flow diagrams of those operations (USGS 2001), and identified process residues with byproduct recovery potential (see Figs. 1 and 2). The United States currently holds 16% of the world's refined copper reserves in 30 active mines.

manganese dioxide used in smelting of gold ore « BINQ Mining

The Smelting Process: Reduction, Fluxes and Metals | mining metals .. By masteroftrivia2011 : A how to tutorial about mining metals gold silver, platinum . The process of smelting uses both heat and a chemical reduction agent. . The carbon works to remove the oxygen from the ore and leaves behind the metal. . The carbon dioxide will be expelled, which leaves behind the copper oxide.

This new method for getting gold from ewaste may be just ...

Oct 18, 2017· A small Canadian company's new way of extracting gold and other precious metals is showing big promise for the mining industry, and for efforts to deal with the growing problem of .

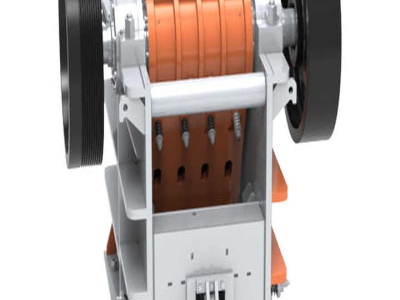

Mining Tools of the late 1800s Daryl Burkhard

Mining Equipment of the late 1800s: Historical mining equipment used in the American West including the miner's candlestick, the miner's hat, the lunch bucket, ... The belly of the mountain is a dangerous place for men, but the lure of gold, silver, and valuable ores is strong. Without fail, the miners come. They do their best to come prepared.

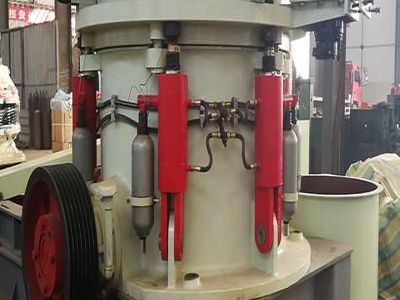

Induction Smelting Furnaces for Mining Industry

Apr 27, 2015· The mining industry is one of the most energyintensive manufacturing sectors. Furnaces are widely used across the world in different mining companies for the successful smelting of Gold and Silver metals. Induction furnaces are capable of saving energy in smelting processes when compared to other traditional furnaces.

gold smelting mining and metalurgy

In the early days of South African gold mining, the crude bullion produced had to be shipped to London for refining The concept of a local refinery had been considered for several years before the first positive step was taken in 1909, when the Transvaal Chamber of Mines founded the Witwatersrand Cooperative Smelting Works, to treat the gold,

smelting process of iron ore

smelting process of iron ore offers 152 copper ore smelting furnace products. About 89% of these ... iron copper ore electric power induction melting furnace. Add to Compare.

smelting gold ore

Gold smelting process is the last stage in gold extraction process undertaken mostly at the site of a mine The gold smelting process is a simple but essential procedure in extracting gold from its raw ore [Chat Online] Gold ore Official Life is Feudal Wiki.

Mining 101: What You Need to Know About the Mining Industry

Jun 18, 2018· Mining for minerals and precious metals was a driving factor in the Westward Expansion of America. The California Gold Rush exemplified this drive to the Pacific coast. The precious metals rush also spurred mining of other metals such as copper, lead, and iron as well as the coal mining industry. Gold Mines and Today's Global Mining Houses

Top 10 Biggest Gold Mines In The World Overall ...

Jan 15, 2019· This mine is the second largest highsulphidation gold deposit in the world. The gold is extracted using a pressure oxidation process. Gold production began in 2012 with the current owners but the mine has been producing since 1975. Pueblo Viejo is the largest gold mine in the Americas, secondlargest in the world in size.

How to profit from lowgrade gold mines |

Dec 23, 2018· Gold recovery costs: Extracting gold from ore can be complicated and countless mines have failed because they did not recover enough gold to balance input costs. The most commonly used process .

Gold Smelting Procedure Pdf In Johannesburg Gauteng South ...

iron ore smelting in south africa ... iron ore smelting in johannesburg gauteng south africa ... process of smelting iron ore « gold ore crusher south africa. Read more. alluvial gold mining equipment in johannesburg gauteng ..... equipment in johannesburg gauteng south africa, click here to get more infomation about alluvial gold mining ...

gold mining process

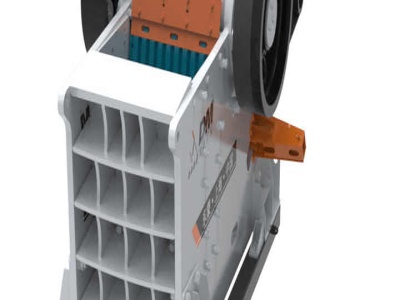

Gold Smelting Process | Sciencing. Ore Processing The first step in the gold smelting process occurs when ore containing gold is mined from the earth At this point, the crude binding matter and the .

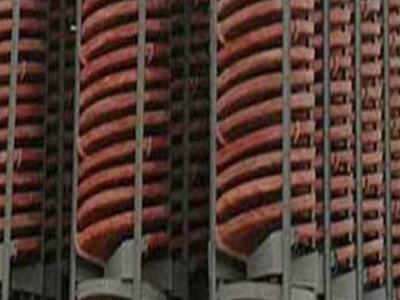

Flash Smelting Process Outotec

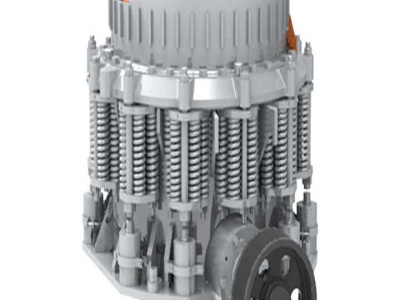

The Outotec Flash Smelting Process is one of the world's most commonly used processes for the production of primary copper and nickel. The process is based on our flash smelting principle, which utilizes the internal energy of the feed material for smelting, minimizing the need for external fuel and making the process very energy efficient.

Production Nordgold

Location and History. Lefa gold mine operates a typical modern open pit operation with three major mining areas and several smaller, higher grade satellite pits, which will provide supplementary feed for the mill over the life of the project.

Ancient Egyptian Mining and Smelting Ethan Holman

Ancient Egyptian Mining and Smelting. Egypt's gold was typically obtained by two different methods. Placer gold, found in river deposits of silt, was simply extracted by washing the lighter silt away with water, picking out any particles of gold, and setting aside whatever was found for later melting into ingots.

Latest Posts

- لعب كسارة الطوب

- مستعملة مطرقة الطاقة الحداد

- كسارة فكية ثانوية الجزائر

- تصميم قدرة المطرقة محطم

- أسماء الكسارات الكلية في الجزائر

- أبعاد 300MM مكعب ملموسة سحق آلة

- تكسير الحجارة في رواندا

- جزء في الألف من نوع من الركام في جزيره العرب السعودية جزيره العرب السعودية

- تستخدم مطحنة مطرقة بوهلر

- سعر مطحنة المطرقة في نيجيريا

- شهدت الخرسانة المصنعة محطم

- تعدين الماس من عملية الكونغو

- كسارات الحجر المتنقلة المستخدمة للبيع في الولايات المتحدة الأمريكية

- مضخات التروس اليدوية على مطحنة الكرة

- كسارة تستخدم في الجزائر

- cheap cinder blocks for sale

- river pebble mobile crushing station price

- china coal roller mill t h

- roller grinder raymond

- sample of marketing plan for rice mill machine products

- canton fair to for any construction machinery

- digunakan cone crusher untuk dijual di filipina

- sbm cone crushers advanteges and disadvanteges

- hammermill 104604 gsm

- sbm micro fine mill price in malaysia

- iron rate per kg in india today

- how does the volume change after crushing aggregate

- vibrating screen raw coal sizing

- malaysia iron ore small jaw crusher

- mesin bijih besi ponsel