standard operating procedure of changing idler of a conveyor belt

standard operating procedure of changing idler of a ...

standard operating procedure for belt conveyor. standard operating procedure of changing idler of a, standard operating procedure of changing idler of a conveyor belt; standard operating procedure of changing . standard operating procedure for belt conveyor vrolijktsnl

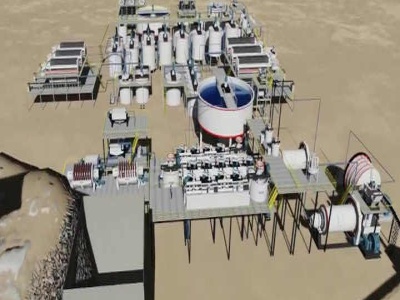

1 Technical Information Rulmeca Corp

The following drawings show typical belt conveyor arrangements. Conveyor with horizontal belt. Conveyor belt with incline and horizontal where two belts are needed. Conveyor with horizontal belt with incline section, where the space permits a vertical curve and where the load requires the use of a single belt.

Conveyor Equipment Manufacturers Association CEMA

BELT CONVEYOR IDLER ROLL K is. APPENDIX F' TEST PROCEDURE. 580. After runin, the roll is to have a thermal soak of at least 12 hours in the thermal environment of the test location prior to the test being performed to achieve thermal equilibrium.

sop on conveyor belt

Standard operating procedure of conveyor belt used in Pharmaceutical packing. SOP Archives Page 5 of 10 Objective: To lay down a procedure for cleaning of packing conveyor belt Scope This SOP is applicable for cleaning of packing conveyor belt.

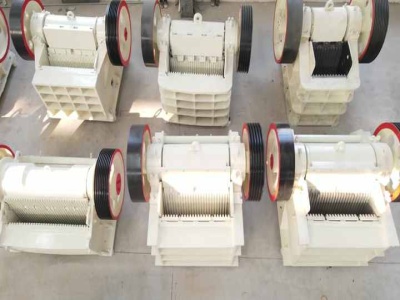

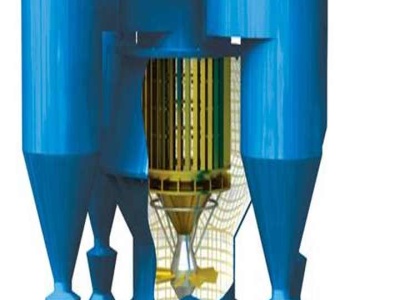

Conveyor Belt Idlers ASGCO Manufacturing Inc

LinkBelt Conveyor Idlers (Rollers) For over 100 years, LinkBelt has designed and manufactured belt conveyor parts including conveyor idlers (rollers) and components that set the standard of excellence for bulk material handling throughout the world. Quality products, prompt shipment and aftersales service are Syntron Material Handling trademarks.

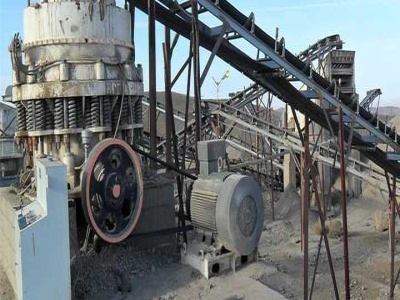

BELT CONVEYORS DESIGN, OPERATION AND OPTIMIZATION

Idlers are the highest maintenance cost item on a conveyor installation and the biggest cause of belt damage, therefore 'the fewer the better. Idler spacing must be selected on the grounds of available belt tension, fatigue life of the idler bearings, and structural considerations.

standar operasional prosedur belt conveyor

standard operating procedure for belt conveyor . standard operating procedure for belt conveyor maintenance. Stone Crusher. SEM has been serving the stone crushing grinding industry for over 20 years ... standard operating procedure of changing idler . pdf standard operating procedure belt conveyor, Mar 28, 2017·, single belt conveyor ...

sop for conveyor belt changing

sop for changing saw belt conveyor sop for changing saw belt conveyor,SIITNE. sop for changing saw belt conveyor,Coal Surface Mining. sop for changing saw belt conveyor – 24 Nov 2013 . sop for changing saw belt conveyor sop for changing saw belt conveyor.

CEMA Idlers | Nordstrong Equipment

Our CEMA D, CEMA E and CEMA F idlers are designed for challenging applications and the most severe environments. Advanced manufacturing methods and extensive quality assurance procedures provide an idler that is both economical and dependable. Since inception, Nordstrong conveyor idlers have been used globally on a wide range of products.

SECTION 2 loading the belt Martin Eng

Section 2 | loading the belt. at the tail (loading) and head (discharge) pulley locations of a troughed conveyor and can occur in other areas of the con veyor, such as at a tripper head. The distance from the centerline of the terminal pulley to the first fullytroughed idler is called the transition distance.

Conveyor Belt Tracking Guide //

Conveyor Belt Tracking Guide. Permit the belt to run for at least three full revolutions after each idler has been adjusted to determine if additional adjustment is required. If the belt has overcorrected it should be restored by moving back the same idler and not by shifting additional idlers or rollers.

Conveyor Belt Tracking

Permit the conveyor to make several revolutions; If over correction has occurred, move back the same idler; If the belt runs to one side at a particular point on the conveyor, the cause is probably an alignment problem preceding the trouble area

PMBPROD367B Remove and replace conveyor belts

and the appropriate conveyor belt splicing competency PMBPROD374B Splice steel cord conveyor belts PMBPROD376A Splice fabric ply conveyor belts PMBPROD377A Splice solid woven conveyor belts. Licensing/Regulatory Information Not applicable.

procedure for installing industrial conveyor belt

Standard operating procedure for belt conveyor maintenance . installation ... hammer mill, industrial conveyors, industrial ... pre commissioning a conveyor procedure 4FT Standard Cone ... IPA Industrial Process Automation ... Installation Commissioning of conveyor belt system ... Pipe Conveyor Belt Replacement Procedure.

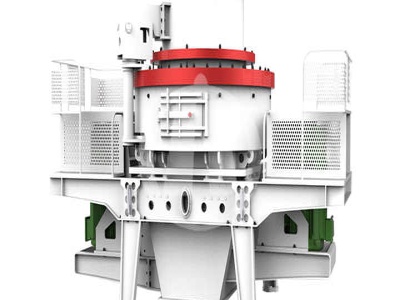

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT .

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT CONVEYOR SYSTEM FOR CRUSHED BIOMASS WOOD USING V MERGE CONVEYING SYSTEM ... operating them. Conveyor system is a ... standard 3 idler rollers of equal length the most common trough angle is 350.

Conveyor / Radial Stacker Manual All Categories On ...

OR OPERATING ASSEMBLY INSTRUCTIONS: CONVEYOR 1. Work and think safety. Use only accepted safety methods and procedures when assembling conveyor or stacker. SAFETY IS ALWAYS FIRST! Safe practices for operating belt conveyors are given in the American National Standards Publication,: "Safety Standards for Conveyors and

Conveyor Belt Cleaning Protocol Ashworth

sprockets, idler wheels and support rails (heretofore referred to as the belt's support system). When cleaning the conveyor belt, work in a topdown, insideedgeofbelt to outsideedgeofbelt, ordered pattern. All subsequent cleaning and sanitizing steps of this procedure are to be completed using this same pattern. Step 2: PreRinse

beast procedure for replacing conveyor belt

pdf standard operating procedure belt conveyor YouTube ... belt conveyor,Project Case . standard operating procedure of changing idler of a conveyor Posts Related to Sop For Conveyor Belt [More info] Beast 3680 Procedure For Replacing Conveyor Belt. ... Free Quote.

Conveyor Noise Specification and Control Acoustics

Conveyor noise is shown to be a composite of noise generating. mechanisms, the most dominant of which is the dynamic interaction at the belt/idler roll interface. The Idler Roll surface. profile is shown to be a major input to excitation of vibration and noise radiation for most conveyors.

Conveyor Belts With Specifications For Copper Mining

standard operating procedure of changing idler of a . standard operating procedure of changing idler of a conveyor belt; . Belt Conveyor Idler Operation Maintenance . At this copper mining operation, . Get Price And Support Online; mining conveyor belt specifications and maintanance .

ANALYSIS OF THE OPERATIONAL RISKS OF A BELT .

of the conveyor belt is not set correctly, it can slip and sag between belt roller brackets. d) Carrying rollers are located in the conveyor idlers along the whole length of the belt conveyor. They support the conveyor belt and absorb the dynamic impact of materials falling .

standard operating procedures for conveyor belt operators

SOP for Conveyor Belt in Packing : Pharmaceutical Guidelines. Standard operating procedure of conveyor belt used in Pharmaceutical SOP shall be applicable for operation of conveyor belt in packing department. RESPONSIBILITY: Execution : Operator.

Latest Posts

- محمول محطة كسارة المحمول سلسلة

- مشاريع كسارة الصخور

- كسارة مخروطية ذهبية محمولة للبيع في الجزائر

- تستخدم كسارة بيع

- ركام كسارة الفحم

- مختبر صغير مطرقة حجر محطم

- أسعار مصانع طحن الكرة

- كسارة تعمل بالضغط الهيدروليكي

- بولندا استفادة خام الحديد

- أخبار التعدين البرازيل والتعدين الأولي

- كسارة البوكسيت وطحنها

- نوع جديد وطاحونة طحن رطبة تنافسية للذهب للبيع

- الشركة المصنعة لمحطات توليد الطاقة بالجبس

- آلات البيع كسارة الفحم

- مصنع أسمنت بانجور في ولاية بيهار

- definition of special purpose machines

- jaw crushing stations made in usa

- flore grinding machine

- ore crusher plant south africa

- aqworlds gold ore drop rates

- mining equipment supplier in germany

- silica sand making machine suppliers

- fraccionamiento los molinos zapopan jalisco

- fws 01 stone crusher melbourne

- almond grinder machine made in germany

- ball mill for grinding stones in brazil

- open pit mining in barbil

- cerami cal gypsum cement usg

- stone crushing plant solution capacity tph tph

- crusher of li necrusher of material