steel production process

Egyptian Steel Production Process

Production Process. Egyptian Steel is capable of producing square billets of 130mm×130mm and 165mm×165mm configurations using steelmaking / casting route of Consteel Melting + Electric Arc Furnace + Ladle Refining + Continuous Casting. At Beni Suef Al Sokhna plants, bigger size billets (165mm×165mm) are directly rolled into different...

Production process for billets and blooms — Sandvik ...

Production process for billets and blooms. Steel melted in the normal way can be remelted in the VAR (vacuum arc remelting) furnace to produce a steel with a low content of nonmetallic inclusions. Several grades of Sandvik stainless steel are available as Sanmac®, stainless steel with excellent machinability for reduced tool wear and increased cutting speeds.

Fabrication

Fabrication is the process used to manufacture steelwork components that will, when assembled and joined, form a complete frame. The frame generally uses readily available standard sections that are purchased from the steelmaker or steel stockholder, together with such items as protective coatings and bolts from other specialist suppliers.

Steel Industry |

STEEL INDUSTRY. In the early 1990s approximately threequarters of all steel production was accounted for by traditional integrated steel mills, which undertook every step of the steel making process, converting mixtures of iron ore, limestone, and coke (made from coal) into .

The Process of Galvanizing Steel California Steel Industries

The Process of Galvanizing Steel Whereas its combination of strength and formability, as well as the abundance of iron ore, has made steel one of modern civilization's most important raw materials, its "Achilles' heel" is its tendency to rust.

Production design for plate products in the steel industry

manufacturing constraints and production quality metrics, and to produce a feasible design and schedule within 30 minutes on a standard desktop computer. Production process We now describe the specific steel production process modeled in this paper. The goal of the production process is to satisfy orders for rectangular steel plates.

Steel making process – ArcelorMittal

Steel scrap has been selectively collected for several decades and is recycled as a valuable raw material for steel production. In the steel production, following stages are identified: production of pig iron; production of liquid steel; hot rolling and cold rolling; applying a metallic and/or organic coating.

Quality and Operation Management System for Steel .

Abstract—A new quality and operation management method is proposed for products in steel production processes. The proposed method is based on multivariate statistical process control, that is one of the applications of principal component analysis.

Steel Wikipedia

Steel was produced in bloomery furnaces for thousands of years, but its largescale, industrial use began only after more efficient production methods were devised in the 17th century, with the production of blister steel and then crucible steel. With the invention of the Bessemer process in the mid19th century,...

Simplified Process for Making Stainless Steel | Columbus ...

The hot rolling process begins at the reheat furnace where the slabs are heated to between 1 100 and 1 300°C, depending on the stainless steel grade. The slabs are then rolled on a reversing four high mill to gauges between 65 and 25mm. Thinner gauges are rolled down further on the Steckel mill.

ArcelorMittal to use hydrogen in steel production process ...

Steel manufacturing giant ArcelorMittal is to explore the industrialscale use of hydrogen in the steel production process for the first time. ArcelorMittal's Hamburg steel plant. As part its strategy to reduce CO2 emissions, hydrogen will be used at the firm's Hamburg plant for the direct reduction of iron ore.

Coke Production US EPA

There has been a steady decline in the number of coke plants over the past several years for many reasons, including a decline in the demand for iron/steel, increased production of steel by minimills (electric arc furnaces that do not use coke), and the lowering of the coke:iron ratio used in .

Manufacturing Process | Steel sheets | Products | Nippon ...

Coated Steel Sheets Production Process. Manufacturing process video. HotRolled Steel Sheets and Coils. ColdRolled Steel Sheets and Coils. Coated Steel Sheets. Contact Information. For further product information. Product Quotes, and inquiries without complete information required in inquiry form may not be responded to. Selection of inquiries ...

Process Optimization in Steel Industry: In the Words of ...

The industry experts say that the plate intermediary materials design process is the most complicated and difficult among all the steel product design processes." Of all the intermediary materials above, the mother plate is one of the core materials for producing steel plates.

Control of Pollution in the Iron and Steel Industry

POLLUTION CONTROL TECHNOLOGIES – Vol. III Control of Pollution in the Iron and Steel Industry D. L. Doushanov ©Encyclopedia of Life Support Systems (EOLSS) prevent, reduce, or eliminate adverse environmental consequences in the iron and steel industry. From the standpoint of the new millennium there must be realized a change

1A Manufacturing Process for Iron and Steel

The smelting and refining process for iron and steel in the BFBOF process involves the carbon reduction of iron ore (Fe 2 O 3) in the BF to make molten iron, and decarburization of molten iron in the BOF to make molten steel. Major reducing agent in the BF is the carbon monoxide gas (CO) generated by the oxidation of the carbon (C) in coke.

ANALYSIS OF THE PRODUCTIVITY IN STRUCTURAL STEEL ...

The complexity of Steel Fabrication process is originated in the uniqueness of steel projects like bridges, car parks, powerplants, etc. This makes processing, routing and resource or labor requirements different for each product within a steel fabrication shop floor.

Latest Posts

- السعر والمعدات من كسارة الصخور

- مطاحن sawa

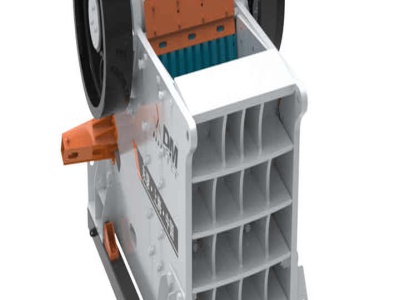

- كسارة الفك للخرسانة

- بدء كسارة الحجر جديدة

- ملامح المطارق كسارة الصدم

- كسارة الفك المزدوجة المستخدمة

- كسارة الفك في الامارات

- منتجات مطحنة sbm طحن mtw

- والتعدين الغبار كسارة تصميم

- أفضل طريقة لطحن البنتونيت الصوديوم إلى مسحوق

- شركات فحص الكسارة

- الذهب ماكينات التعدين العربية السعودية

- كسارة فكية معتمدة

- مستعملة الحجر الجيري إنتاج سحق

- مطاحن ريموند السعودية

- kerikil menghancurkan mesin canada crusher untuk dijual

- ft cone crusher for sale australia

- how to treat oxidized ore in flotation

- jow crusher model 2000

- coal crusher hoods

- crusher combination roll

- diatomite milling equipment manufacturer

- ultra grander india of liter

- ramco cement price per bag in kerala during may

- clay brick making machine clay brick making machine price

- case study of indian spinning mills

- used closed ciruit small stone crushing plant

- small micronizer ball mill singapore

- medium sized gold wash plant for sale

- premium pulverizer