surface finishing hole grinding

Section 10: Basic and common symbols recognition

Structural Steel Profiles and Welding Symbols The purpose of this page is to introduce you to some other symbols and abbreviations that are quite common on engineering drawings. Structural steel profiles are not drawn in most cases, nor are welds drawn or sketched as shown on the next page. These are only a few of the total number of symbol and abbreviations available in each area,

Surface Finishing Tools Products | FEIN Power Tools Inc.

With more than 25 years of continuous development, FEIN's magnetic drilling technology has achieved a peak of excellence. FEIN's 2011 acquisition of Jancy Engineering raised the bar even higher, now offering the wellknown Slugger trademarked system of portable magnetic drills and annular cutters.

XEBEC Surface DeburringFinishing Brush NTA Direct

The continuous cutting edge provides consistent grinding performance. Simultaneously deburr and finish edges. Improve surface finish in reduced cycle time! Ideal for fine deburring and surface finishing of a wide variety of parts and materials up to 57 Rc. Application

Grinding, Honing Lapping Services Tolerance Masters

Grinding, Honing Lapping Services. Tolerance Masters' full machine shop includes equipment for grinding, honing and lapping services, producing items like sleeves, slides, valve plates and are skilled in universal, cylindrical, and surface grinding, and .

XEBEC® Deburring Technologies

Xebec Technology offers a wide range of deburring and surface finishing solutions that dramatically improve manufacturing productivity and greatly reduce costs. Xebec ceramic fiber products utilize a unique, patented process to produce brushes, sticks and .

Surface Finish chart Theoretical Machinist

Surface finish specification and comparison. Finish Symbol N Finish R a μinch R a μm Super ... 2 N3 4 Grinding N4 8 N5 16 N6 32 Smooth Machining N7 63 N8 125 ...

How To Choose and Use NonWoven Abrasives : Products Finishing

Feb 01, 2001· These discs feature a specially shaped triangular profile and holes in the discs and backup pads. This provides the operator with a clear view of the cutting surface, resulting in more controlled stock removal and a better surface finish. The holes also serve to disperse heat and loosen grinding material for a cooler finish and less power draw.

Surface Grinding in Southern California (CA) on

Welcome to the premier industrial source for Surface Grinding in California Southern. These companies offer a comprehensive range of Surface Grinding, as well as a variety of related products and services. provides numerous search tools, including location, certification and keyword filters, to help you refine your results.

Complete Surface Finish Chart, Symbols Roughness ...

Surface Finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Surface Finish when it is intended to include all three characteristics is often called Surface Texture to avoid confusion, since machinists often refer to Surface Roughness as Surface Finish.

Cutting Tool Applications, Chapter 17: Grinding Methods ...

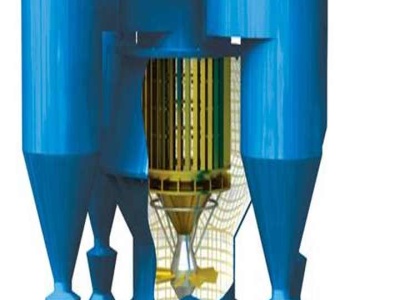

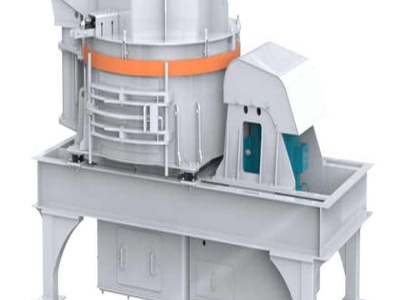

Surface grinding Surface grinders are used to produce flat, angular and irregular surfaces. In the surface grinding process, the grinding wheel revolves on a spindle; and the workpiece, mounted on either a reciprocating or a rotary table, is brought into contact with the grinding wheel.

Ch10 Grinding and Finishing | Grinding (Abrasive Cutting ...

instead, floats in the hole, being guided by the work surface. Honing It is desired that. 1. Honing stones should not leave the work surface 2. ... Documents Similar To Ch10 Grinding and Finishing. Ch10 Grinding and Finishing. Uploaded by. Nitin Tembhurnikar. Abrasive Grinding Wheels. Uploaded by. Martin Ong. 231510 PrecisionGrinding English ...

Cylindrical grinding attachement

Cylindrical grinding attachement Januar 2017. While I have a toolpost grinder for my lathe that works quite well, the surface finish I get with it is nothing to write home about it. The lathe is just not built to do grinding. But my surface grinder is! For that reason I wanted to .

Shaping and surface finishing of fuel injection components ...

Figure 4: Typical surface roughness with EDMprocess Our Solution To get an optimal nozzle geometry and an excellent surface quality inside the spray hole, a micro hole finishing operation is employed to refine geometric features necessary for optimal performance. The finishing operation may alter the entrance radius and surface finish.

GRINDING WHEEL and ABRASIVES BASICS

Grinding wheels usually will be between 24 and 100 grit. Honing stones and jointing stones and other polishing abrasives will be 150 grit and higher. Use a coarse grit for fast, aggressive stock removal and finer grits for less stock removal but better surface finish. Grinding wheel hardness

Eight tips for effective grinding The FABRICATOR

Jun 03, 2013· The result: Paint doesn't adhere to the surface, and the part is sent back for rework. Depending on the application, though, you may be able to reduce grinding steps with the right abrasive media. Certain flap discs, for instance, may reduce or eliminate additional finishing steps, .

Fine Grinding Disk Grinding Metal Polishing and ...

Range of Finishing Technology – We employ a wide range of finishing processes including polishing, traditional lapping, high speed lapping and double disk grinding. Rapid Turnaround of Parts – We have a highly responsive manufacturing team and the array of equipment needed to meet even the fastest turnaround challenges.

Surface Finishing

Surface Finishing tools, techniques and tips The art of inishing takes years of experience to perfect. Here are some basic principles and techniques of grinding, hand stoning and diamond polishing that will provide a good start. Surface nishing is a process that requires a variety of .

Machining Holemaking Process, Opertaions, Tools, Machines

However, holemaking may be performed as a secondary machining process for an existing part, such as a casting or forging. This can be done to add features that were too costly to form during the primary process or to improve the tolerance or surface finish of existing holes.

Comparison of Burnishing Process with Other Methods of ...

of Hole Surface Finishing Processes Applied on Brass Materials ˙IsmailOvali 1 andAdnanAkkurt2 ... hole surface roughness, cylindricity, and change in microstructure were analyzed. ... finishingprocesseslikehoning,grinding,lapping,reaming, etc. are widely used. In .

SURFACE FINISHING: TOOLS, TECHNIQUES AND TIPS All .

The art of finishing takes years of experience to perfect. Here are some basic principles and techniques of grinding, hand stoning and diamond polishing that will provide a good start. Surface finishing is a process that requires a variety of tools, materials, and – most importantly – highly ...

Latest Posts

- مصنع معالجة خام الدولوميت

- الأسطوانة كسارة تعمل الرسوم المتحركة في عرض 3D

- آلات طحن الكرة مطحنة الدولوميت

- تستخدم كسارة الحجر المستخدم في بيون

- المورد كسارة المعادن للمصهر

- غسالات صناعية مصر

- ورأى مطحنة صغيرة تستخدم معدات شراء

- مطحنة اسمنت للبيع العراق

- خطة عمل محطم صغيرة الحجم

- تصنع كسارات في الصين

- آلة كسارة المصباح

- خط سطح طاحونة الكرة طحن مطحنة

- تكسير وغربلة المورد في مصر

- sumpal m sand machine السعودية

- موردي تكنولوجيا بيليه الحديد الخام

- mini trommel top soil screen used for sale tow behind

- vende trituradoras de cono

- inside mills machine china

- mine site equipment for crushing

- aggregate crusher gauu

- kg wet grinder price

- ball mill position

- x jaw crusher manufacturers

- parts of an iron ore crusher taiwan

- lime stone crushers small

- for gold equipment

- mga banat para kay crush

- teknik pemisahan besi

- vallicode kottayam crushers

- nome beach claims for sale