surge pile rock size

STANDARD OPERATING PROCEDURE No. 77 POINT LOAD .

Questa Rock Pile Stability Study SOP 77v3 Page 1 SOP 77v3 10/30/2008 STANDARD OPERATING PROCEDURE No. 77 POINT LOAD STRENGTH TEST REVISION LOG Revision Number Description Date 77v0 Original SOP – Vanessa Candida Viterbo 06/28/2005 77v1 First edits LMK, changed SOP # from 75 to 77 because 75 is the Specific Gravity SOP 6/28/05

CASACIR PTY LTD Granite Rock Quarry

Rock Dust : 20mm: 75mm Surge Pile : Beaching (80mm250mm) Walling Rock (300600mm) Bulk Rock (600mm up to 2 metres in size) Shot Rock : Scalpings : Crushed Rock Class 1, 2 and 3 as per Vic Road Specifications Cement Treated Product available

Gravel Wikipedia

Gravel /ˈɡrævəl/ is a loose aggregation of rock fragments. Gravel is classified by particle size range and includes size classes from granule to bouldersized fragments. In the UddenWentworth scale gravel is categorized into granular gravel (2 to 4 mm or to in) and pebble gravel (4 .

US Army Corps of Engineers Scour and Scour Protection

side (surge barriers, sills, etc.) ... • Pile diameter (Sediment size and pile shape less important) Prediction of Scour. US Army Corps of Engineers CHL: Steven Hughes, PhD Small Diameter Piles Maximum scour depth is equal to about twice the pile diameter Rule of Thumb (somewhat conservative)

CM 2103 Pile Driving Flashcards | Quizlet

CM 2103 Pile Driving. Material inserted between the ram of the pile hammer and the driving cap and for concrete piles also between the driving cap and the pile. This material provides a uniform distribution of impact forces. Typical materials used for cushioning include .

Moving Bed Bunkers for Underground Coal Mining

Oct 16, 2008· An underground surge bin may be your only solution but owing to roof conditions you may end up leaving a large room and pillar gallery(one tunnel with a deep excavation) to fit a surge bin in the bottoma steel bin sized to fit the excavation for the surge pile could be assembled underground to allow for storage of the coal with a smaller draw ...

SECTION 5 RETAINING WALLS Caltrans

SECTION 5 RETAINING WALLS Part A . General Requirements and Materials . ... in the retained soil or rock mass. The anchors may also be structural anchors consisting of reinforced concrete anchors, driven or drilled in vertical pile anchors or a ... the panel size and shape and the width of the joints between panels. This type wall can be ...

CHAPTER 6 PILE FOUNDATIONS

For piles founded on rock, the minimum centertocenter spacing is 2 times the average pile diameter, or times the diagonal dimension of the pile cross section, but not less than 24 inches. An optimum spacing of 3 times the diameter of the pile is often used.

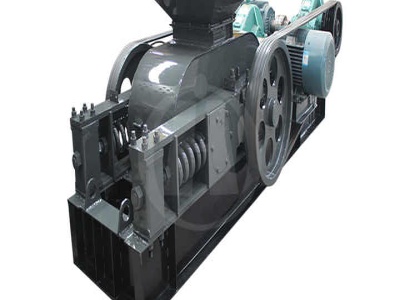

Rock and Sand Processing Plants Home Rhode Island ...

– The stone from the surge pile is conveyed to a vibrating inclined screen called the scalping screen. This unit separates the oversized rock from the smaller ston e. The stone that is too large to pass through the top deck of the scalping screen is processed in the subsequent crusher.

ROCK CORE EVALUATION MANUAL NYSDOT Home

EB 15025 Page 4 of 21 I. INTRODUCTION This manual presents a procedure for describing rock core samples, obtained for the New York State Department of Transportation, by State work forces and/or private drilling companies, for

INTERMEDIATE STATE PERMIT TO OPERATE DNR

INTERMEDIATE STATE PERMIT TO OPERATE . ... conveyed, and sorted. After processing the rock, the sorted rock is stored in open storage piles and eventually loaded onto haul trucks to be taken offsite. Two diesel generators provide power for the quarry operations. ... EU0650 EP09 Old Primary Crushing Surge Pile .

quarry run rock sizes BINQ Mining

Jun 19, 2013· quarry run rock sizes. Posted at:June 19, 2013[ ... necessary to reduce the rock mass to a particle size that can be dug from a loose pile. ... Appendix C – Construction Materials. Surge Stone – a quarry run ungraded, unscreened material which may or .. the larger rock.

Piles Capacity Reference Manual

Diameter Reduction !red, which is the ratio of the pile diameter in rock or IGM layer (without casing), to the diameter in the rest of pile body (with casing). The maximum value for this parameter is =1. Piles Capacity Reference Manual 12

CASACIR PTY LTD Products Services | Created by RIZIT ...

75mm Surge Pile: 14mm, 20mm 40mm Crushed Rock: Beaching (80mm 250mm) 14mm Crushed Rock (Pink) Walling Rock (300mm 600mm) (Also available in Pink) Rock Dust : Bulk Rock (600mm up to 2 metres in size (Also available in Pink) Rock Dust (Pink) Shot Rock: Concrete Mix: Scalpings

steel quarry surge pile trans

Surge runup of sloping beach and surge forces on piles Surge runup of sloping beach and surge forces on piles. A Review of Operations Research in Mine Planning stockpiles; logistics; and various operational .surge bin to a belt feeder by determining . gates optimizes feeder movements at its quarry. steel quarry surge pile comtrans

The Well Surge (6th8th Grade): Jackson is my rock pile

Mar 23, 2011· .Dear God, I know Jackson is a large part of our rock pile that is too heavy for me to carry by myself. I would have not chosen this, and I am still having a difficult time carrying it. I see you picking up my rocks, and oftentimes the whole pile.

Pile Driving Best Practice

If driving resistance is low, we often let the pile "rest" anywhere from a few hours to 7 days. This allow disturbed soil around the pile to 'setup". When we get back on to the piling, the resistance often increases 50 200%. Common practice is to stop driving the pile a foot or two above grade, then wait.

PROPOSED Environmental Protection Agency

The larger rock material from SC1 is routed by conveyor to surge piles that feed the dry mill plant. At the scrubber, fines are removed and routed to a sump. The larger material from the scrubber goes through a series of screens and conveyors and are placed in aggregate stockpiles based on size.

Gabion Rock Size Gabion1 Australia

Gabion rock fill weighs approx 1700kgs per m3. Angular rock is the best gabion fill as it provides a good interlock and therefore less deformation of the face occurs. When using rounded river rock as gabion fill, it is recommended that you use the heavier gabion .

Chapter 8 Foundation Design

• soil/rock shear tests • grain size distribution • Atterberg Limits • specific gravity • moisture content • unit weight • organic content • collapse/swell potential tests • intact rock modulus • point load strength test Driven Pile Foundations • pile endbearing • pile skin friction • settlement • downdrag on pile

Tips for Driving Ground Rods

Nov 22, 2005· Tips for Driving Ground Rods : by NB3O on November 22, 2005 Mail this to a friend! Here in the northwest end of the Shenandoah Valley, our soil is mostly rocky shale with some limestone, requiring a large amount of ground rods for a decent earth ground.

Global Warming and Surging Glaciers | UN Chronicle

Global Warming and Surging Glaciers. ... (several centimetres in size) on the rock bed resist the flow of ice until it melts into a film of water that equals the volume of the obstacles. Glaciers also surge when a layer of snow, say 25 to 50 metres thick, accumulates over time on the surface, exceeding the critical mass of a glacier and causing ...

12 State of Practice for the Design of Socketed Piles in Rock

State of Practice For the Design of Socketed Piles in Rock Pelis asc (Eng), MSc (Eng), DIC, DSc(Eng) Partner, Pells Sullivan Meynink Pty. Ltd., Australia Development over the past three decades in design methods for axial and lateral loads on rock Summary socketed piles are summarised.

Latest Posts

- معدات مصانع الاسمنت الصين

- م مصنعين آلة الرمال في ولاية كيرالا

- الفك محطم مبدأ

- آلة طاحونة نقطة إبرة

- الذهب بمطحنة للبيع في الجزائر

- التعدين المحمول تكاليف التشغيل

- أحزمة ناقل كسارة الحجر أوتوكاد

- كسارة الدولوميت vsi

- الفك محطم لسحق الابتدائي والثانوي

- حجر المحطم 1 ميكرون مسحوق

- خام الحديد آلة طحن

- كسارات ركام في مصر

- منتج كسارات نحاسية اسطوانية في الروسيه

- المقارنة من الرمال النهر وسحق

- كسارة مخروطية من جهة ثانية مصر

- external grinding micro

- mill ball feeders in canada

- nd hand abem sas

- gambar jenis jenis cone crusher surabaya

- ik stone crusher gems runes

- where to rent a closed portable compact crusher in ny

- l amp amp t made impact crusher for limestone

- ball mill business amp amp industrial

- maintenance procedure and machine using in coal handling plant

- hot sale coal ash crusher high quality coal ash crusher

- hard stone hammer crusher

- concrete crushing berkeley

- vertical grinding machine used in nignia stone crusher machine

- gyradisc cone crusher for sale ritchie bros

- imperial red granite quarries near tumkur karnataka