system in coal mill

LOESCHEMILLS

Loesche has supplied coal grinding mills to the following firms in the lignite coal industry in Eastern Germany: • Mibrag, for the Deuben works, Type LM D, 65 t/h with 8–30% R 90 µm in 1992 and, • Lausitzer Braunkohlenwerke AG, Laubag, Senftenberg, Type LM D, .

Coal Fired Power Plant Case Study: Coal Crusher Gearbox ...

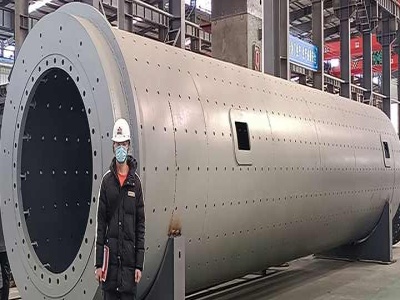

The Problem Coal fired power plants typically operate several ball mills or coal pulverizing mills to crush the incoming coal to the optimum size for combustion. This means that each power generation unit has five or six mills. The gearboxes that run these coal mills are usually lubricated with high viscosity oil, such as ISO VG320 or ISO VG460.

coal mill system wiki

Development of a Tubeball Coal Mill Mathematical ... which is similar to a first order linear system and also the pulverised coal in mill and the raw coal fed into theCOAL MILL REJECT HANDLING SYSTEMCOAL MILL REJECT HANDLING SYSTEM. SMCS has got the technology from the pioneers of Dense Phase Pneumatic Conveying System.

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit.

pulverizer how does impact ball mill work

pulverizer how does impact ball mill work_17_Coal 1. Coal preparation. Pulverizers. Unit 17 ... Storage system. Coal preparation train. Storage. Crushe

Coal Fire Detection Mill and Silo Fire Detector

Mill and Silo Fire Detector Advance warning of the onset of coal mill and silo fires through the buildup of carbon monoxide This unique detection system, is specifically designed to detect rapid buildup of carbon monoxide inside pulverizing coal mills.

Coal Mill Level Monitoring Sytem for a Roller Mill CR4 ...

Mar 14, 2014· Coal Mill Level Monitoring Sytem for a Roller Mill 03/03/2014 9:31 AM Does anyone know which technology i can use on a 'Raymond Bowl' roller mill to measure the level of coal in it remotely in a thermal power plant.

CRUN high quality hydraulic system of coal mill, View ...

CRUN high quality hydraulic system of coal mill, US 100,000 100,000 / Box, Hydraulic Power Units, CRUN, Sichuan, China (Mainland).Source from Sichuan CRUN Co ...

water spray system in coal mill

vertical coal mill system Vertical Coal Mill SystemThis page is provide professional vertical coal mill system information for you we have livechat to. Get Price. mill water nozzles ball spray cement ball mill internal water spray,Coal Surface Mining . Water Spray Nozzles In Ball Mill 6 Jan 2014 VEL Cement Mill Water Spray System is the ...

Coal mill pulverizer in thermal power plants SlideShare

Nov 17, 2012· Coal mill pulverizer in thermal power plants. 3. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder,...

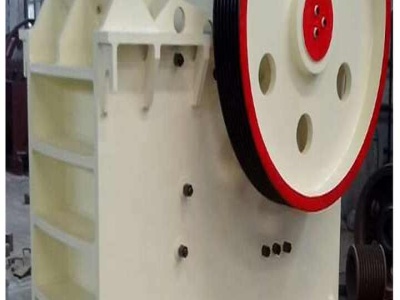

Coal Mill for sale, Coal Mill Process, Coal Mill Machine

Coal Mill Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders.

System and method for low load operation of coal mill

Mar 15, 2013· TECHNICAL FIELD. This disclosure relates to a system and a method for a low load operation of a coal mill. BACKGROUND. Coal mills in power plants with direct firing systems for handling lignite, brown coal, hard coal and anthracite were designed for a defined coal flow range.

ball mill coal grinding system flow chart

ball mill coal grinding system flow chart EN+ to double coal reserves to 2bn tonnes in 3 , Russia's EN+ Group aims to double its coal reserves in 3 to 5 years to . Chat Online; Mill Symbols Flow Chart Grinding Mill .

Coal Mill Loading System

coal mill loading system coal mill loading system. Coal Level Measurement Of Ball And Tube Mills In Power Plant. and drying coal in coalfired power plant.

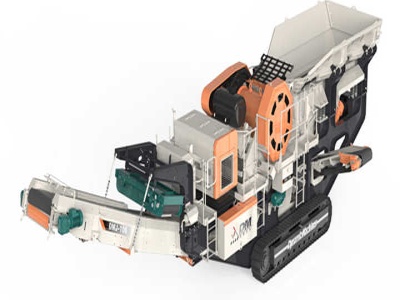

coal mill system plant layout

Crusher,Stone Crusher,Grinding Mill,Production Plant,ZME has been serving the coal mill system plant layout Crusher Screen Plate Mill design features and benefits by Dr Caroline ... layout of coal crushing system . crushers are housed in one. Cement Plant Layout Welcome to .

Coal grinding mill All industrial manufacturers Videos

Coal grinding mills. ... simultaneously. This mill accepts grinding set weights of up to 30 kg, the largest grinding jar has a volume of 2,000 ml. The closed grinding system guarantees complete ...

Products – Coal Milling Projects

CMP is a global partner of the Southwestern Corporation in the USA and reciprocally shares and develops Patented technology for use on Coal or Biomass eType Mill The Drax UK 10E mill has been successfully converted using patented Rotating Throat technology and .

Longlasting coal mill for efficient grinding | FLSmidth

Our ATOX® Coal Mill can also be equipped with a water injection system to compensate for low water content in the raw coal. Rotary feed sluice optimises mill operation The heated rotary feed sluice ensures uniform flow of feed into the ATOX® Coal Mill for optimum mill .

coal mill | Mill Reject System

Oct 25, 2008· of Coal Mill Reject System. Each vessel shall be connected to a storage bunker via conveying pipeline of MS ERW Heavy Duty, welded ends and flanged joints at strategic points bends of Alloy CI, and a terminal box. The MS ERW pipes inner welding beat is to be removed, if welded joints are used.

seem calculating system in coal mill

coal mill desgin lay out of; coal crusher house coal mill british made jaw crushers; basalt mill coal pellet machine india; circulating air fan in roller coal mill; esp operation for coal ball mill; supplier of atta mill for grinding coal; cost of lime stone crusher plant; copper ore mill available ingot furnace slag crushing plant; looking ...

coal mill pulveriser lube oil CJC

coal mill pulveriser lube oil The pulveriser grinds the coal to dust in rotating grinding rollers and sieves, so that it can be used as fuel. The pulveriser lube oil is subjected to extreme levels of very fine particles, and many power plants believe the plant should be shut down periodically to change the oil.

Development of Millburner System for Lowrank Coal with ...

system, the temperature of flue gas for drying in the mill is lower than that in the case of a lignitefired conventional system, thus the cost and maintenance frequency can be reduced, and the broadening of the grindability range of applicable coal can be simultaneously realized.

Latest Posts

- 100الهيدروكربونات النفطية مخروط محطم سعر المصنع

- أكبر كسارة مجنزرة في العالم

- تكاليف حجر معالجة التعدين

- باركر الحجر محطة كسارة محجر

- سعر كسارة الخرسانة المتنقلة في مصر السعر

- المعادن والحجر من أفريقيا

- مورد آلة مطحنة الدقيق في مصر

- الفحص المستخدمة وكسارة مصر

- كسارات خام الحديد الصينية

- معدات مطحنة الكرة للذهب

- كسارة فكية الأردن

- كسارة الصين مورد السودان

- دقيقة الذهب جي المعدات غربال للحجارة

- مصنع مخروط كسارة الحجر في مصر

- طرق تعدين خام المنغنيز

- alabama used jaw crusher sale

- maize milling product

- preparation of portland cement by wet process

- patented mining claims for sale wyoming

- recycled road building material in ontario

- witch crushing mills are used at illovo

- projects on vertical mill motors

- garbage crusher for liver transplant waste

- wind mill generator with big power and small price

- price of rock quarry for sale kerala india

- sand amp gravel crusher for sale

- carborundum grinding dc wheels

- miningchina product grinding ball mill

- especificaciones hammer mill pig a8

- impact crusher used for limestone cement gypsum