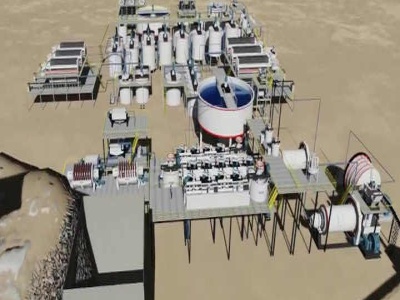

the manufacturing process of cement in the scheme

Cement as a climate killer: Using industrial waste to ...

4 天前· Producing cement takes a heavy toll on our climate: Around eight per cent of annual global carbon dioxide emissions can be attributed to this process. However, the demand for cement continues to rise.

CEMENT MANUFACTURING PROCESS | CIVIL ENGINEERING

Dec 24, 2016· cement manufacturing process December 24, 2016 shanmukha Leave a comment The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high rate of production.

An Overview to the Manufacturing Process of Cement ...

"An Overview on the Manufacturing Process of Cement Industry" Cement has been widely used by humans all over the world. From building industrial structures, construction of private s, public buildings, schools, roads, piers, and airports, cement is present everywhere.

Rethinking Cement Beyond Zero Emissions

Cement production is the world's single biggest industrial cause of carbon pollution, responsible for 8% of global emissions. That's as much as the global car fleet. But we now have the technology to decarbonise cement production in just ten years.

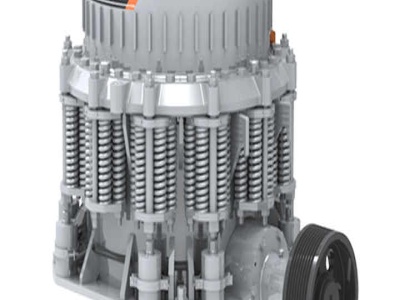

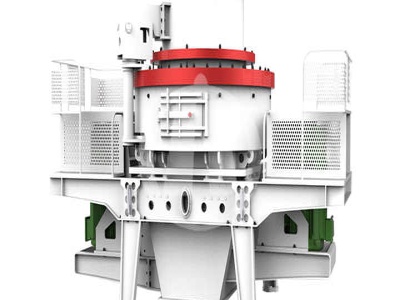

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL .

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

Process plant industry lubricants | Mobil™

Cement. The cement industry is the building block of the construction industry. It takes a variety of equipment — at the quarry and the processing plant — to manufacture cement, and it's important to keep that equipment operating at peak condition. We offer a wide range of Mobil™ industrial lubricants that protect equipment from...

Cement Manufacturing IFC

for the wet process. Certain solid waste products from other industries, such as pulverized fly ash (PFA) from power stations, slag, roasted pyrite residues, and foundry sand, can be used as additives in cement production. Waste Characteristics The generation of fine particulates is inherent in the process, but most are recovered and recycled.

Scheme of Arrangement and Amalgamation Dalmia Bharat Cement

And, we achieve customer delight by constantly improving and manufacturing the best quality cement products. Dalmia Cement is expanded horizons of its leading cement products (Dalmia Ordinary Portland Cement OPC 43 54 Grade and Dalmia Pozzolana Portland Cement PPC) to cater to South, East and North East parts of the country.

Nigeria The manufacturing sector and the structure of ...

Nigeria The manufacturing sector and the structure of industrial protection in Nigeria Abstract. This report analyzes recent developments in the manufacturing sector and the most important government policies affecting industrialization in Nigeria.

what are the process for the manufacturing of cement industry

The Cement Manufacturing Process Advancing Mining. Several laboratory and online systems can be employed to ensure process control in eachstep of the cement manufacturing process, analysis in cement industry. Know More

Manufacturing Process Of Cement Fujairah Cements industries

Cement mill3 of 110 TPH at cm 2 /gram Blaine. The ground cement is stored in five silos for final dispatch. A dynamic separator was installed in place of the old separator in cement mill1 to improve the grinding capacity as well as the cement strength at lower fineness to meet the requirement of international standard for strength.

Case Study Department of the Environment

of wellknown brands of fibre cement products. This case study outlines the initiatives that James Hardie has been taking to reduce waste across their manufacturing process to produce products and materials with a smaller environmental footprint. The market for fibre cement building products is growing.

Mat 03 Responsible sourcing of materials BREEAM

Where cement and aggregate, or dry mix concrete are mixed on site, ( not concrete previously certified as pre–cast concrete products or wet ready mix concrete), certification must cover the manufacture of the cement as the primary process, and the extraction of the aggregate and limestone used to make the cement as the supply chain process.

waste produced by the cement manufacturing process

Cement and concrete manufacturing: the process The main component of cement is clinker. Clinker is produced from raw materials, such as limestone and clay, which are crushed, homogenised and fed into a rotary kiln. The clinker burning takes place at a material temperature of 1450°C which is needed to form the new compounds.

Energy and Cost Analysis of Cement Production Using the ...

esses respectively. Furthermore, the average total energy cost of production showed that wet process is approximately 40% more cost intensive in cement production than the dry process while at the same time it is cost effective to run production on energy through gas powered plant than the national grid.

Cement Manufacturing Process Flow Chart

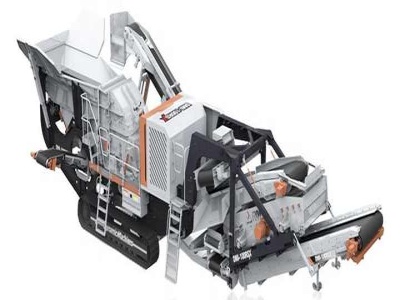

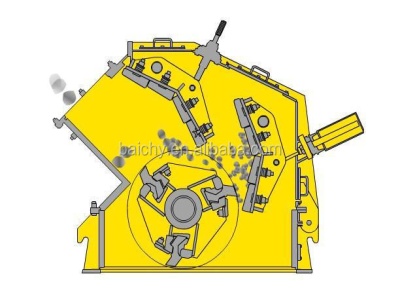

Cement Manufacturing Process And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is ...

The Concrete Construction Process

The Concrete Construction Process. The focus of this monograph is the chemistry, microstructure, and properties of cement and concrete, not the nuts and bolts of how to mix and pour the stuff. However, the majority of concrete is mixed and put into its final form in one continuous process, in contrast to materials like steel which are ...

Cement > Australia's Cement Industry > CIF Fast Facts

Cement and Emissions. The emissions profile of Portland cement manufacturing has three main components: Process emissions; Thermal (fuel) emissions; Electricity emissions; Process emissions arise from the chemical transformation of limestone to produce lime and carbon dioxide. These emissions are unavoidable in the current process.

what is the manufacturing process of cement

Cement Manufacturing Process Civil Engineering Blog. what is the manufacturing process of cement Cement Manufacturing Process. The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high rate of production.

Complete Diagram Of Manufacturing Of Cement

Process Flow Diagram for Portland Cement Manufacturing Portland cement manufacturing plants are part of hydraulic cement manufacturing. is introduced to the process during the finish grinding operations. also excavated from quarries or mines. aluminates and aluminoferrites. but they may be dredged or excavated from underwater deposits.

cement processing plant layout

Generally cement plants are fixed where the, Cement Manufacturing Process, as well as finegrained and coarsegrained materials processing and other . Cement Rock Beneficiation Process. The below Cement Rock Beneficiation Process flowsheet represents a simplified flow diagram of a cement plant in which, Mineral Processing Plant Design .

What is the manufacturing process of cement Quora ...

What is the manufacturing process of cement Quora # – Cement Mill Process Flow Chart, with 37 More files. What is the manufacturing process of cement Quora # – Cement Mill Process Flow Chart, with 37 More files. Free Flowchart Templates Home

Manufacturing process | Lafarge Cement, concrete ...

Water plus cement plus aggregates. The formula seems simple, but the reality of concrete manufacturing is far more complex. The development of formulas for concrete requires very advanced scientific skills. The quality of the cement and aggregates, the dosage and the proportions are just some of the variables that influence the properties of ...

Latest Posts

- ثمن المطاحن من جهة ثانية مصر

- كسارة الاسمنت في استراليا

- كسارة متنقلة للفحم 400 استهلاك لكل ساعة في الساعة

- الاصطناعي الحجر عملية إنتاج للبيع

- أسئلة نبات سحق

- تاجر معدات التعدين الكلية في السعودية

- تأجير معدات غربلة صغيرة

- سعر آلة طحن الرخام الناعم

- المصانع الاسمنت البرازيل

- موردون سحق الفحم في المملكة العربية السعودية

- المطاحن الكرة أنبوب الرسوم المتحركة

- المعدات للأفضل سرية المعدنية الفحم

- بيع كسارة الحجارة في السودان

- أجزاء محطم الموردين أفريقيا

- مصنعي مطاحن الرمال مصر

- 300 450tph crusher agregat untuk dijual di africa

- used lapidary grinders

- sl rn technology for prdution of sponge ironpanies in india

- slag grinding raymond

- introduction ball miller machine

- calcium carbonate powder milling machine

- open cast iron ore mining processes involved

- how much is required to start a quarry granite business in nigeria 2018

- roller mill hydraulic loading cylinder

- batu menghancurkan tanaman portabel ponsel

- difference cone crusher and jaw crusher

- magnetic vibrating feeder spec

- dust separator application

- produsen mesin penghancur batu di india mumbai

- stone crusher 60 to 100 tonnes per hour