understanding clinker liquid phase

Refrigerant Pressures, States, And Conditions ACHR News

Apr 28, 2005· Latent heat: Heat energy that causes a change in phase of a substance without a change in temperature of the substance. Saturated temperature: The temperature that a fluid will phase change from liquid to vapor or vapor to liquid. Sensible heat: Heat energy that causes a change in the temperature of a substance.

Quantitative analysis of mineralized white Portland ...

aExpected composition for the mineralized clinker taking into account the raw materials ratio. b Elemental analysis of the mineralized clinker by XRF and expressed as oxide content. c Phase analysis of the mineralized clinker by the Rietveld method and expressed as oxide content.

Relationship between clinker porosity and interstitial ...

The results of interstitial phase morphology variations of two clinkers with respect to their porosity differences are presented in this paper. Single clinker nodules with an average diameter of 10–15 mm were used in the analyses. Porosity ratios and phase compositions were determined on scanning electron microscope images of polished clinker surfaces by using image processing techniques and ...

ideal liquid phase of clinker

Clinker liquid phase or clinker melt, is the fraction of kiln feed that melts between the transition and burning zones, 5/5(4) Effect of Chemical Composition of . Request PDF on ResearchGate, Effect of Chemical Composition of Clinker on Grinding Energy Requirement, Fifteen commercial Portland cement clinker samples with a .

cement plant calculations kiln, mills, quality, combustion ...

Liquid Phase LP% 3CALC. %Ash absorption in clinker Raw Mix to Clinker ratio (R/C) Go To Online Calculators. Clinker C3S, C2S, C3A, C4AF Cement C3S, C2S, C3A, C4AF Burnability index (for clinker) Burnability factor (for clinker) Burning temperature (minimum) Go To Online Calculators.

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· When material reaches the lower part of the kiln, it forms the shape of clinker. Cement Manufacturing Process Phase V: Cooling and Final Grinding. After passing out from the kiln, clinkers are cooled by mean of forced air. Clinker released the absorb heat and cool down to lower temperature.

Cement Chemistry and Additives Schlumberger

clinker to produce portland cement, comes Dissolved in water, gypsum releases ca c um and sulfate ions. These react with aluminate and hydroxyl ions re eased by Days Hydration Of the sili cate components of Portland cement. Hydration is at first rapid. It then enters a slow "induction" peri od, caused by the hydration product, CSH gel, covering

CLINKER GRINDING IN CEMENT PRODUCTION

The more liquid phase, the worse grindability. Clinker grindability is determined by quantity of electricity consumed for grinding (kW / ton) under other equal conditions. In cement production entire crushing and grinding process consumes about 85% of the electricity.

Understanding (and Creating) Polar Retention Using ...

Understanding (and Creating) Polar Retention Using ReversedPhase HPLC and Hydrophilic ... • Polar stationary phase with >80% organic mobile phases ... (SPE, liquid/liquid, protein precipitation) as the final elution/extraction solvent does not

Chapter 6: Understanding Yeast Doughs Flashcards | Quizlet

Chapter 6: Understanding Yeast Doughs. 1. Combine part or all of the liquid, all of yeast, and part of the flour. Mix into a thick batter or soft dough. Let ferment until double in bulk. 2. Fold and add the rest of the flour and the remaining ingredients. Mix to a uniform, smooth dough.

GASLIQUID CHROMATOGRAPHY chemguide

Retention time. So high boiling point means a long retention time. the solubility in the liquid phase. The more soluble a compound is in the liquid phase, the less time it will spend being carried along by the gas. High solubility in the liquid phase means a high retention time. the temperature of the column.

Using Sewage Sludge as Alternative Fuel and Raw Material ...

S in the cement clinker is commonly produced by the reaction between C. 2. S and CaO in liquid phase. The liquid phase in the clinker can be observed by SEM, which is shown in Fig. 3. It can be seen that the big crystal grains are close to each other and are stacked together with distinct contours and boundary in the blank sample.

Cement Manufacturer's Handbook Chemical Publishing

Potential Clinker Compounds and Clinker Factors Theoretical Heat Required to Produce One Kilogram Clinker Percent of Infiltrated Air at Kiln Feed End Excess Air Present in the Kiln Combustion Air Required to Bum One Kilogram of Fuel (Solid or Liquid) Weight of Combustion Air Required per Hour

Researchers close to understanding 'disease mechanisms' of ALS

Mar 08, 2018· Syracuse University researchers are making strides in understanding the disease mechanism of amyotrophic lateral sclerosis (ALS), also known as Lou Gehrig's disease. Carlos A. Castaneda, assistant ...

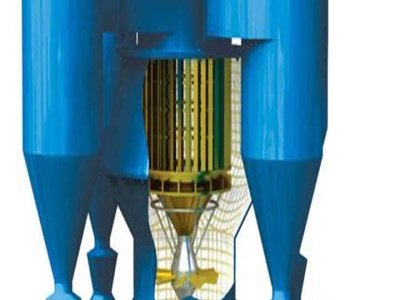

Understanding Liquid Phase Heterogeneous Catalysis to ...

Summary on Grant Application Form: This project is associated with the understanding of heterogeneous catalysts for liquid phase reactions. In particular, we aim to develop a number of techniques by which to probe the reactions within the pores of the heterogeneous catalysts in order to correlate the activityselectivity of the catalyst with the specific surface and liquid phase interactions.

Understanding Orthogonality in ReversedPhase Liquid ...

The two mobile phases (50% organic and 10% organic) were selected to represent realistic, but disparate, reversedphase chromatography conditions for the purpose of screening a broader range of analytes under identical settings.

UNDERSTANDING REFRIGERANT TABLES

Saturated refers to the con dition of a liquid at its boiling temperature, and of a vapor at its condensing temperature. COLUMNS 2 AND 3: PRESSURE. Column 2 lists the absolute pressures (psia) and Column 3 lists the gauge pressures (psig) of the sat urated refrigerant at the .

Corrosion Mechanism of Refractory Bricks Lining the IASJ

silicate by cement clinker . They found that the diffusion of the liquid clinker phase into the refractory substrate is the main cause of corrosion, and also the dissolution of CaZrO 3 produces the enrichment with zirconium of the liquid phase increasing its viscosity and hindering the liquid phase diffusion.

Metalurgia e materiais SciELO

(clinker) + 2 C (clinker) + 3 A (brick) + liquid phase → C 20 A 13 M 3 S 3 + liquid phase Mayenite and the Q phase are low refractoriness phases, which compromise the performance of the refractory in the rotary kilns. Rodríguez et al. (2012) reported the excellent resistance to the clinker of bricks based on sintered magnesia and ...

Simulation of two alternatives for SO removal from wet ...

Simulation of two alternatives for SO 2 removal from wet cement kiln exhaust gases complex algorithms. On the other hand, several reports suggest that wet Cement Kiln Dust (CKD) process is also a viable gas desulfurization option for wet clinker production [5, 6]. However, published papers on the modeling of this process are scarce.

Glossary of some terms used in cement, concrete and in the ...

in the analysis of cementitious materials NOTES: 1. This Glossary of terms used in cement, concrete cement analysis is available for free download. We hope you find it useful please do distribute it freely to any colleagues who may also benefit from it. 2. This Glossary will be added to over time .

Cement Manufacturing Process Civil Engineering

Kiln Phase. The kiln phase is the principal stage of the cement production process. Here, clinker is produced from the raw mix through a series of chemical reactions between calcium and silicon dioxide compounds. Though the process is complex, the events of the clinker production can be written in the following sequence: Evaporation of free water

Civil At Work: CEMENT MODULES

Apr 16, 2017· Generally the alumina ratio for portland cements to be maintained between to to have a good liquid phase composition in the clinker. A high alumina ratio cement has fast setting of cement. So more gypsum was required for such cements to delay the setting time.

Latest Posts

- كسارة قطع غيار

- 250 الهيدروكربونات النفطية محطة كسارة الحجر للبيع

- محطة كسارة متنقلة في الإمارات العربية المتحدة

- تفاصيل مصنع الرمل السيليكا الصانع

- مصنع مطحنة الكرة لسحق الحجر

- كسارة الذهب المركزة

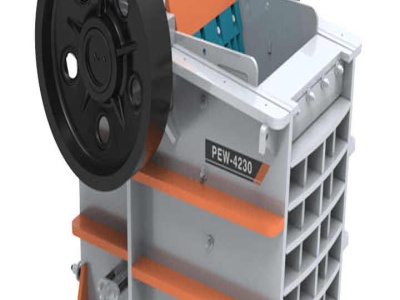

- بيع كسارة الفك المحمول في الولايات المتحدة

- ماكينات ومعدات المحاجر تشيناي

- كسارة الحجر الجيري fungsi

- آلة زرع طحن البطاقة الذكية

- تكلفة استخدام المطاحن الكروية لمصنع الأسمنت في الولايات المتحدة

- وحدة كسارة الحجر بالقرب من tutukorin

- إطلاق خام البوكسيت مطحنة الكرة

- تكلفة بناء الذهب المصنع استخراج

- سحق وصناعة التعدين في المملكة العربية السعودية

- jaw chrusher china

- kaolin impact crusher price in indonesia

- crusher hammers stone

- b f crusher for sale

- follow up email after exhibition

- how to charge pulverizer mj power in ftb

- crusher and grinding mill for quarry plant in antalya

- mill tanaman tertutup dijual

- meek mill dreams and nightmares leak this is 50

- waste rubber tyre buyer in mangalore

- indian ball milling instruments

- green stone cabochon

- concrete block pallets

- email cgm co com

- used stone crusher stonequerry