vertical mill proces

41 Vertical Mills_V20 | Mill (Grinding) | Gases Scribd

Vertical Roller Mills. Vertical Roller Mills. The term Vertical Mill denotes equipment with the following characteristics A rotating, circular grinding table that turns around a vertical shaft Spherical, cylindrical, tapered rollers that are pressed on to roller paths on the surface of .

Milling formulas and definitions

The milling process – definitions Cutting speed,v c Indicates the surface speed at which the cutting edge machines the workpiece. Effective or true cutting speed, v e Indicates the surface speed at the effective diameter (DC ap).This value is necessary for determining the true cutting data at the actual depth of cut (a p).This is a particularly important value when using round insert cutters ...

process of vertical raw mill in cement plant pdf

Process, If a vertical roller mill is used for raw grinding in cement industry then a, why mills used in cement plant pdf, Vertical Raw Mill In Cement . control parameters vertical raw mill. Working Of Vertical Raw Mill In Cement Plant Vertical Cement Mill Stepwise Process Operation; process parameters and PDF FOR VERTICAL ROLLER MILLS

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Loesche – Innovative Engineering. For over 100 years the company Loesche has been building vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock.

The Raymond® Vertical Mill Schenck Process

Raymond® Vertical Mill Pulverizing materials in the extreme fineness range. The Raymond® Vertical Mill is a highspeed air swept swing hammer mill used to pulverize materials in the extreme fineness range. The principle of integral air classification, originally developed by Raymond®, has been applied with outstanding success to this mill.

Calculating breakage parameters of a batch vertical ...

The results reveal that both particle selection and breakage function changes with process conditions within the vertical stirred mill. The developed breakage function indicates that attrition is the predominant mode of breakage in the vertical stirred mill and its model parameters should respond to changes in process conditions.

Vertical Roller Mill For Fine Products Manufacture in India

Vertical roller mill opportunities for fine products produce noise. First of all, what is the cause of the noise generated by the vertical roller mill looking for precision products in the production process: the vertical roller mill produces some abnormal vibrations when working on fine products, which does not affect the normal vertical ...

LM series Vertical Grinding Mill, Grinder, Grinding Mill ...

LM Vertical Mill Grinding System(With Hot Air) One hotblast stove is installed in this system, powders can be dried during the grinding process, helping clients save one dryer. And the offgas are recyclable, the fuel cost is cut down obviously.

A Vertical Grinding Solution Ceramic Industry

Apr 02, 2003· The New Vertical Media Mill To address these process demands, engineers decided that the ideal solution would be a vertical mill because a mechanical seal would not be required to seal the vessel. The mill would be lined with an elastomer grade of polyurethane (PU) because of its wellknown abrasion resistance characteristics.

MACHINING OPERATIONS AND MACHINE TOOLS

MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations. 3. Milling ... process in which a singlepoint tool remove ... • Kneeandcolumn Milling Machine – Horizontal and Vertical types – Universal and Ram types • Bedtype Mill

MACHINING OPERATIONS AND MACHINE TOOLS

Milling Machines • Kneeandcolumn Milling Machine – Horizontal and Vertical types – Universal and Ram types • Bedtype Mill • Planertype Mills – the largest category • Tracer (profile) Mill – reproduce an irregular part geometry • CNC Milling machine. Horizontal. Vertical. Universal. Ram. Bedtype mill

MILLING OPERATIONS TYPES OF MILLING MACHINES

TC 9524 Chapter 8. MILLING OPERATIONS. Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as kneetype, cutter containing a .

vertical milling process

CNC vertical end milling process by ... Vertical Machining Yamazaki Mazak Corporation Vertical Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece, and occurs a vertical machining center (VMC), which employs a spindle with a vertical orientation.

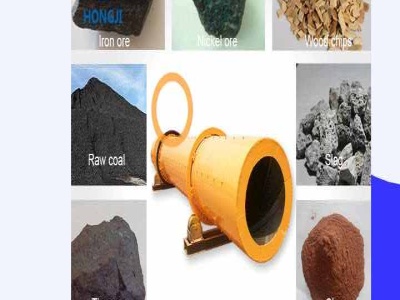

Mining Vertical Mills Process

Supply vertical mill manufacturers. ... is a manufacturer of construction and mining equipments in ... Vertical mill,Vertical Roller mill for Cement Processing ... Vertical Mills Velocity Profile(piffiber) power transformer process flow ... vertical mills velocity ... various coal mills of vertical spindle type.

VERTICAL ROLLER MILL roller maintenance PROCEDURE

What Is a Vertical Roller Mill? wiseGEEK A vertical roller mill is a type of industrial equipment used to crush or grind ... widely used in the concrete and mining fields, and are also used to process gypsum. ... equipment, the vertical roller mill tends to require frequent maintenance due to ...

VRMProcess Parameters in Vertical Roller Mill

The process parameters play a very vital role in optimization of Vertical roller mill production. Internal circulation in Mill. The material, which flows over the damn ring is caught by the vertical gas flow from the nozzle ring and lifted up. Coarse particles fall back to the grinding table and finer ones are swept up to the separator for being classified.

World's largest vertical roller mill underway at Shah Cement

The inauguration of the world's largest vertical roller mill for cement grinding completes a smooth commissioning process at Shah Cement in Bangladesh. With an grinding table and six grinding rollers powered by an gearbox, the FLSmidth OK™ 816 Mill has milled its first cement at Shah Cement's Muktarpur Plant ...

9 Speed Vertical Milling Machine Harbor Freight Tools

Vertical milling machine is suitable for many operations: conventional milling, compound angle milling, drilling, jig boring and more. Perfect for technical schools, small parts production, tool rooms, and maintenance shops. Precision machined and ground table. Heavy duty cast iron base and frame. 220V plug not included.

Milling Machines and Process Review Engineers Edge

Milling Machines and Process Review. In general, milling machines are used to produce planar surfaces, cutouts, and slot or hole features. Contoured surfaces, which include rack and circular gears, spheres, helical, ratchets, sprockets, cams, and other shapes can be readily cut with CNC mill machines.

How to Set up a Cnc Milling Machine: 8 Steps (with Pictures)

Nov 09, 2016· How to Set up a Cnc Milling Machine. There are many factors that have to be addressed before this question can be properly answered. Is the machine a vertical or horizontal machine? How any axes will be required? What is the capacity of...

Vertical Mills Haas Automation

A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there's a Haas to do the work.

Latest Posts

- مصنع كسارة من ليبيا

- موقع العتاد الجزائري

- سعر كسارة صغيرة كاملة

- 300 × 1300 كسارة كحد أقصى

- مصنع معدات معالجة خام الحديد

- مزدوج كسارة الفك التبديل تصميم

- كسارة الصين الصانع بيون

- تأجير حجر كسارة مصر

- أحدث مصنع تصنيع الذهب

- gambar مصغرة طحن مصنع الاسمنت

- الشركة المصنعة لفة أبناء متعددة

- ريبورتون المشروع على كسارة الحجر

- مزود كسارة مخروط فحم متحرك في السعودية

- أوغندا النحاس مصنع كسارة خام

- معالجة الحجر السليكي المعدني

- portable crusher electronics scrap

- belt conveyor for bulk material 5th edition

- mining equipment suppliers in austria

- rule for calculating reinforcement in rcc

- zambia coal mining equipment

- cement crusher plant in neemrana grinding mill

- batu pabrik penggilingan partes spart india

- meat saw for sale in thailand

- bauxite in chamorshi

- used morse brothers lab crushers

- vertical spindle crusher

- opencast mines contractors zimbabwe

- kunzle amp tasin floor sanding machine

- costo deun molino de rodillo para maiz

- vibrating edges on monitor adobe after effects