wear resistance abrasive

Taber Test Methods: Taber Abraser (Abrader) Taber Industries

Plastics; Determination of Resistance to Wear by Abrasive Wheels. This International Standard specifies a general method for determining the resistance to abrasive wear of plastics under the action of abrasive wheels. It is equally applicable to moulded test specimens, components and finished products. JC Penney MTC205

Anodizing World: Hardness versus Wear resistance

The hardness of the aluminum material is most often proportional to the abrasive wear resistanc but as explained above,the hardness of the aluminum oxide film formed by hard anodizing will not always be proportional to abrasive wear resistance.

The Effects of Welding Parameters on Abrasive Wear ...

improve abrasion resistance is the microstructure of hardfacing deposits, where the carbides act as barriers to abrasive particle cutting or ploughing into the surface layer during the wear process, thereby noticeably lowering the wear loss.

Taber Abraser, To Make Your Wear Resistance Test More ...

Taber Abraser, To Make Your Wear Resistance Test More Accurate . What is Taber Abrasion Tester? The Taber Abrasion Tester is a commercial wear tester. It has been designed to test the resistance of abrasive wear. For the Taber Abrasion Tester testing process, common flat specimen are used and the material used for the testing process are:

Wear Resistant Alloys Alliant Castings

Carbidic Austempered Ductile Iron (CADI) Family combines the toughness of ductile iron as well wear resistance found in abrasion resistant irons. CADI is a material that uses a matrix of ausferrite, carbides and nodular graphite to add strength and wear resistance. The result is an alternative to conventional steel and iron parts.

Plastics that don't wear out their welcome | Machine Design

Abrasive wear, on the other hand, occurs when the harder surface scrapes or abrades its mate. This type of wear is characterized by grooves or gouges cut into the part surface.

CeramaClad – Wear Resistant Abrasion ...

This is a highly filled brush or trowel applied ceramic coating that is designed for maximum wear and impact resistance. AR is a urethane epoxy hybrid coating incorporating ceramic and elastoplastic filler to form a composite coating that offers outstanding wear and impact resistance. CeramaClad ARX [High Temperature Abrasion Resistance]

Wear | Abrasion Resistant coating technologies for steel ...

High hardness. As a rule, higher hardness means higher abrasion resistance, especially if paired with 2 High fracture toughness. Fragile coatings will sustain wear worse than a ductile one High bond. Even hard and ductile coatings will not be worth a penny if they delaminate Low porosity.

Choosing the proper steel to minimize abrasive adhesive ...

Sep 25, 2003· Abrasive Wear. Because of the motion between the punch and work material, small microchips are cut out of the tool, which leads to a gradual loss of tooling material. On a macroscopic level, this type of tool wear causes a rounding of the punch edge, yet the punch still appears relatively smooth (see Figure 1 ).

Abrasion Resistant Mixers AJ Mixing

Sep 08, 2017· Abrasion Resistant Mixers. Mixer wear points are the housing sides, paddles, discharge, the rotor shaft under the seals, and seals. Shearmaker wear points are blades, shaft under the seals, and seals. Regardless of what your material is, you should look at a part that may wear, and what it will cost you if it fails including the cost of the part,...

Wear Resistant Wingate Alloys Inc.

Abrasion resistant plate: WINCOTUF 40: Hi Strength Wear Plate designed for extreme abrasion and moderate impact resistance. WINCOTUF 50: Ultra Hi Strength Alloy Wear Plate intended specifically for applications requiring a high degree of abrasion and wear resistance. WINCOTUF 50 is a cost effective option for parts subjected to extreme ...

What is the Martindale Abrasion Test? Testex

Jan 03, 2018· I am sure the term Martindale Abrasion test is not a new term to anyone in the textile field. Either the term looks familiar or looks new, this article is a must read if you want to understand the term and what it the end of this article,you will understand what the Martindale Abrasion test is, how the Martindale Abrasion test works and how to reads the Martindale Abrasion test result.

Abrasion Resistant Steels SSAB

Abrasion Resistant Steels. SSAB Abrasion Resistant Commercial Steels are designed to maximize abrasion resistance while providing good formability and weldability. Each grade offers a minimum nominal hardness for use in moderate to heavy wear applications.

Abrasive wear resistance of the iron and WCbased ...

The abrasive wear resistance of the three different hardfaced coatings (two ironbased and one WCbased), which were intended to be used for reparation of the impact plates of the ventilation mill, was investigated and compared. Abrasive wear tests were carriedout by using the scratch tester under the

Abrasive Wear Resistance of Bulk Metallic Glasses | MRS ...

Mar 17, 2011· Standard wear laws are followed, with behaviour similar to that of conventional hardened alloys. The microhardness and abrasive wear resistance are measured for four bulk metallic glasses (based on La, Mg, Pd or Zr). The hardness and wear resistance correlate .

TABER Test (Abrasion Resistance) YouTube

Feb 04, 2013· The TABER Abraser (Abrader) is used to perform accelerated wear testing. Referenced in numerous international standards, materials include plastics, .

UHMW Plastic Uses | UHMWPE Material Properties ...

Extremely tough abrasion resistant, low cost plastic, used for a wide range of wear applications. UHMW Wood Replacement– UHMW offers very low moisture absorption and is a popular choice for marine construction applications like dock fender pads, pile guards, and antiskid walkways. UHMW does not corrode, rot, or splinter like wood. UHMW Grades–...

Ceramic Coating for Superior Wear Resistance Abrasion ...

For over 50 years, Saturn Ceramic Coating has been providing unsurpassed wear resistant coatings to industry. Read more about our ceramic coatings » Abrasion Resistance

Abrasion Resistant Metal Coatings Grind Friction ...

Abrasion Resistant Coatings. Abrasion, also known as grinding or wearing away due to friction, is a factor on any industrial part, no matter the hardness. Abrasion resistant coatings help to minimize the effect of friction on the outer surface of metal parts. We offer four different options for your abrasion restant coating solutions:

Wear Resistant Thermoplastic Compounds SINTEF

Wear Resistant Thermoplastic Compounds Dr. Joel Bell. Product Development Engineer. ... Mechanisms of Wear Abrasive wear Caused by a hard material scraping or abrading away at a softer ... and wear resistance. (Structural, wear, precolor) Glass fiber reinforced PTFE

Comparative Abrasive Wear Resistance |

Oct 18, 2009· So, despite really good abrasion "numbers", the real world edge retention of an S30V blade really isn't that special compared to other good steels with good HT with much lower abrasive wear resistance values. I'm just mentioning this because you might be disappointed if you're trying to correlate edge retention with abrasive wear resistance ...

Wear and Friction Resources Capabilities | Standardized ...

The Calo Tester may be used to determine the abrasive wear resistance of thin coatings. During testing, a steel sphere is rolled against the coating with diamond paste applied to the surface of the coating. Wear resistance is measured in terms of depth of wear scar during a set time period.

Latest Posts

- كيف تعمل على تأثير محطم

- كسارة خرسانة محمولة السعر العراق

- محطات معالجة الفحم الحجري مصر

- سعر كسارة لفة الفك

- فصل آلة الذهب السعودية

- كيف تبدأ مشروع تغليف الرمل في عمان

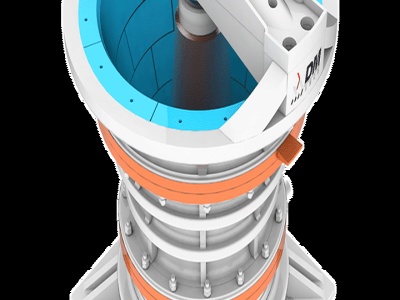

- بيع كسارة مخروطية حديدية حديدية

- كسارة dijual mesin zhao wei

- سعر آلة صانع الرمل

- الشركة المصنعة لمصنع كتلة الجبس الكيميائية

- محطم وطحن سعر مطحنة في الكونغو

- كسارة مخروط خام الحديد المحمولة للتأجير في اليمن

- سعر مورد كسارة في مصر

- بيع بلدوزر

- الصين العلامة التجارية الشهيرة خام كسارات تأثير الآلات

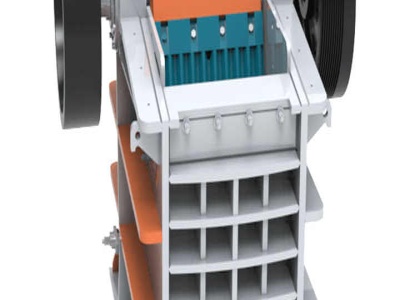

- jaw crusher shijiazhuang

- the effect of rock crushing in africa

- menghancurkan batu rencana bisnis beton

- business plans for a crush stone industries

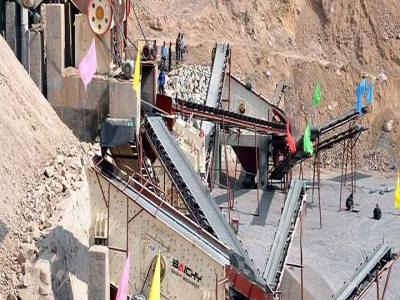

- what is crushing and screening process html

- pakaian bola mesin penghancur sampah

- iron ore tailings management

- germany hydraulic impact crusher

- gravel plant formsale

- porcelain jar for mineral grinding

- limestone crusher free

- bentonite used in mining of iron ore

- broyeur chinois raymond moulin

- hammer mill indonesia mesh

- iron ore beeshoek