what does grinding in manufacture of cement mean

role of grinding in cement manufacturing

what does grinding in manufacture of cement mean. what does grinding in manufacture of cement mean. what is the role of gypsum. if we are % gypsum for grinding cement and same clinker we add 4 ... Get More Info. ... Use of grinding aide in cement manufacturing cement grinding aid These ...

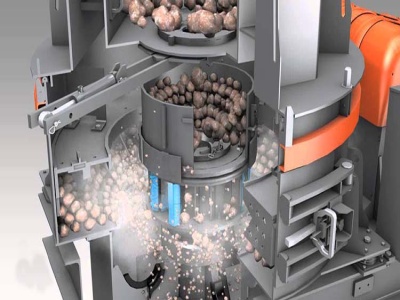

What Is Crusher In Cement Plant

Cement crusher used for crushing limestone, bauxite, gypsum, coal Cement crusher is the important cement manufacturing machine used in cement production line. ... Types of cement crushers are used in cement grinding plant.

grinding for paint manufacture

grinding for paint manufacture grinding machine for paint Alibaba. Grinding machine for paint products are most popular in Domestic Market, Mid East, and Africa. You can ensure product safety by selecting from certified suppliers, including 5,819 with ISO9001, 1,918 with ISO/TS16949, and 620 with Other certification.

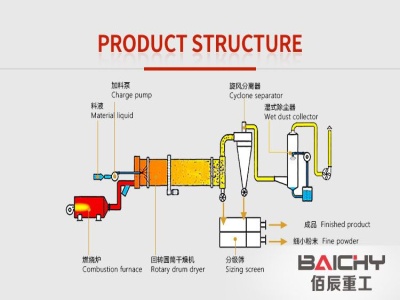

What Is A Grinding Mill Plant

Grinding Plant is made of jaw crusher, bucket elevator, electrovibrating feeder, main unit, optional equipment, blower, centrally electric control system, etc. » More; grinding mill in cement plant Gold Ore Crusher. Vertical cement grinding mill supplier, Cement production line, Cement plant.

differences between abc stone and recycled concrete BINQ ...

road crush washed stone difference – Grinding Mill China. It can be used under paving stone and concrete, .ABC Stone (Crushnrun) Washed Screenings » Free Online Chat. . what is difference between recycled stone and . »More detailed

degree of filling definition in cement mill

The physical meaning of this assumption is that at some point in the ..... initial velocity = ft/min (Kiln % filled)... Service Online. ... Cement Manufacturing Technology · Grinding Milling Systems ... friends please explain me what do you means from degree of kiln ... Degree of kiln filling means volumetric filling percentage ...

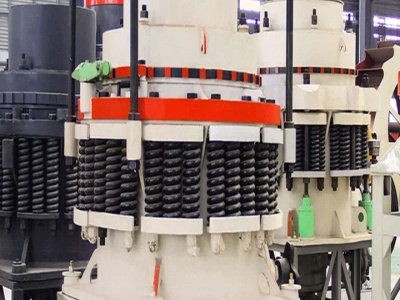

what is ball mill grinding

Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

grinding fine powders what is great

China Grinding Fine Powder manufacturers Select 2017 high quality Grinding Fine Powder products in best price from Find great deals on eBay for fine powder grinder. >>Chat; air classifier powder processing grinding mills. RSG Inc manufactures air classifiers fine grinding mills for the minerals, chemical, cement, lime and metal powder industries.

What Does Cement Ball

The cement mill. Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. Get Price And Support

Frequently Asked Questions The Concrete Network

Frequently Asked Questions ... What does it mean to "cure" concrete? Can it be too hot or too cold to place new concrete? ... The clinker is very finely ground to produce portland cement. A small amount of gypsum is added during the grinding process to control the cement's set or rate of hardening. TOP.

what you mean by portable grinding and grinding machines

what you mean by portable grinding and grinding . what you mean by portable grinding and grinding machines. grinding machine used in india. mineral grinding machine is used toportable mineral grindinga windmill is a mill that converts the energy of wind into rotational energy by means of vanes

Cement Grinding Process In Details

Cement Grinding Process In Details originconcepteu. Cement manufacturing process | CEMBUREAU cement grinding process in details,A twostep process Basically, cement is produced in two steps: first, clinker is produced from raw materials, The second phase is handled in a cement grinding mill, which may be located in a different place to the ...

consultanship in manufacture of grinding

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting, Consultanship In Manufacture Of Grinding; Get More; what does grinding in manufacture of cement mean. Consultanship In Manufacture Of Grinding what does grinding in manufacture of cement mean Home >ShowRoom >what does grinding in manufacture ...

Understanding the Marking System for Grinding Wheels

All abrasive wheels are marked with: The range of material markings, grit sizes, grades, structures and bonds depends on the product and the manufacturer, but the table above gives a general outline of common markings seen on abrasive wheels. The maximum operating speed is marked on every large grinding wheel (above 80mm in diameter)...

Blaine

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

Atmospheric Emissions From the Manufacture of Portland Cement

ATMOSPHERIC EMISSIONS FROM THE MANUFACTURE OF PORTLAND CEMENT INTRODUCTION This report has been prepared to provide reliable information on actual and potential atmospheric emissions from portland cement man ufacturing plants and on methods and equipment normally employed to limit these emissions to satisfactory levels.

What is the purpose of adding gypsum in cement?

Gypsum is a mineral and is hydrated calcium sulfate in chemical form. Gypsum plays a very important role in controlling the rate of hardening of the cement. During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process.

OSHA Grinding Regulations | Legal Beagle

The Occupational Safety and Health Administration (OSHA) grinding regulations protect workers who use potentially dangerous grinding equipment from occupational injuries and illnesses. OSHA holds employers responsible for ensuring grinding equipment and protective gear meets OSHA safety standards, and employers who do ...

Cement hydration

The reactivity and performance of cement is a culmination of the effect of the different impurities on the number of defects and morphology of the crystal structure of the different phases. This is why cement can vary not only from one source to another, but also between batches from the same source. Effects of temperature on hydration

Secondary Processes: Pavingexpert

Secondary Processes is the term used to describe texturing techniques that are applied to paving products following initial manufacture. This page extends the coverage given on the previous pages which considered the techniques involved in Concrete Paving Manufacaturing and Paving Textures and should be read in conjunction to those pages.

Composition of cement Penn State Engineering

Composition of cement. Manufacture of cement Portland cement is manufactured by crushing, milling and proportioning the following materials: Lime or calcium oxide, CaO: from limestone, chalk, shells, shale or calcareous rock Silica, SiO 2: from sand, old bottles, clay or .

What Is Cement Mill Main Drive

what is cement mill main drive 2oceansracing. what is cement mill main drive Selection of AC Induction Motors for Cement Plant Selection of AC Induction Motors for Cement Plant This paper focuses on the selection of AC induction motors for cement in the specification of cement millwhat is cement mill main drive,The Advantages of PortlandLimestone Cement| Concrete The .

what is the specific ation of cement thermal mill

Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill. What Is The Specific Ation Of Cement Thermal Mill;... FL ball mill for cement grinding. · FL ball mill for cement grinding. and can be adapted to specific allow for longitudinal thermal expansion... Specific Information About The Raw Mill .

Latest Posts

- كم يكلف مصنع غسيل تروميل s8 s7

- تستخدم مخروط محطم المحمولة للبيع

- تستخدم مطحنة الكرة للبيع في المملكة العربية السعودية

- moulin concasseur broyeur الزراعية السعودية

- مصنعي آلة طحن

- على الرمال خط أسماء مولد فن

- لفاف محطم مصر

- شراء الفك صخرة محطم

- تكلفة الكسارة الصخرية في تاميل نادو

- محجر كسارة للبيع في مصر

- الاستخدام الصناعي للحجر الجيري

- مصغرة الرمل آلة النخل

- مطلوب طوب طيني بالسعودية

- مطحنة المطرقة تصميم سحق التربة

- ثلاثة كسارة vsi الأيل

- sand mining equipment in south africa

- mini grinding and milling machine philippines

- spare parts machinery

- cement mill hajq net

- compressor used to make super snorkel

- stone crusher manu in maharashtra amp3b its price list for maharashtra

- corex x impact crusher

- feasibility study for a sugar plant in pakistan

- patterns for can crushers

- flow on machine in cment industrie

- sale alberta conveyors

- extraction of granite

- mining exploration results

- gold dry wash blueprints pdf

- high efficiency sand washer used in artificial sand