working law of vertical roller mill

how to work accumulaters vertical roller mill

Vertical Roller Mill Operation Grinding Mill. Vertical roller mill is Shanghai zenith industrial,in order to solve technical ... the hydraulic cylinder rod, accumulator, etc, can exert enough pressure rollers to ... Please note that you do not need to have a mail programme to use this function. Chat Now

working purpose of vertical roller millDBM Crusher

working law of vertical roller mill allosushi53fr. Vertical roller mill working principle is just like this: main motor rotates by designed power, and material falls onto millstone via three gate devices, and then is flung to the lower part of roller. Get Price.

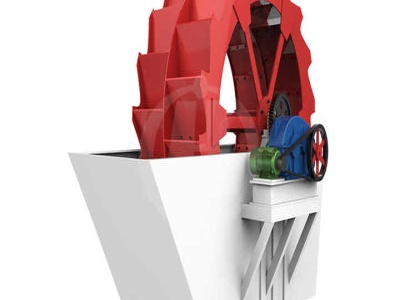

Ball Mill For Ceramics

Ball Mill For Ceramics The akins classifier is actually popular within the concentrator in order to classify nutrient sands mixing along with ball mills to create the shut circuits procedure, as well as utilized in the law of gravity concentrator in order to grading ore as well as good dirt along with the desliming, dehydration along with other ...

Vertical Roller Mill, Vertical Roller Mill Operation And ...

vertical roller mill working principle. Vertical roller mill has many different forms, but its working principle is basically the same. All these forms of machinery with the grinding roller (or the equivalent of the grinding roller grinding parts), grinding roll along the horizontal circular locus motion on the disc, is applied in the vertical pressure roller grinding through external, make ...

working of vertical roller mill

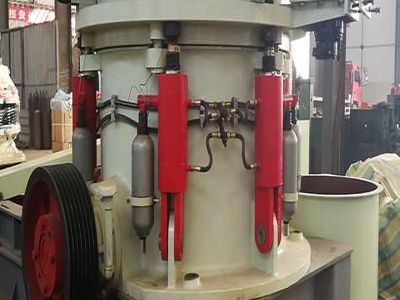

Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the .

Mill Noise Level Report Ref A FvdM GIBB

Cement Mill Noise Level and Attenuation Report Page 2 1. Executive Summary The study was conducted to establish if the noise radiated by two different cement grinding technologies, a conventional ball mill and a vertical (roller) mill, would be sufficiently attenuated at the boundaries of the proposed sites to adhere to regulations.

vertical gravity take up belt conveyor design Mineral ...

vertical gravity take up belt conveyor design offers 124 vertical screw conveyor design products. . A wide variety of vertical screw conveyor design options are available to you, such as . Innovative design tube screw conveyor for light industries on sale ..

Vertical roller mill for raw Application p rocess materials

Vertical roller mill for raw materials Application p rocess Raw material process Background Grinding raw materials needs lots of energy. Tube mills had been used for grinding, but the energy efficiency level was lower. Therefore, the introduction of highly efficient grinding equipment was anticipated. Descriptions

vertycle roler mill

LM Vertical Roller Mill Features and Benefits, Working Principle. Low running costs: It adopts the technologies that vertical roller mill material directly on the disc, with low energy consumption; for the roller isn't make contact...

how to cost a vertical roller mill

slag grinding plant,vertical roller mill,slag mill,grinding mill, Vertical mill function more complete, structure of cost, material cost, high technical cost will directly influence on the market price formation Secondly, the mill price also determined by market demand, the law of market value P .

working rule of vertical roller mill

vertical roller mill working principle Vertical roller mill has many different forms, but its working principle is basically the same All these forms of machinery with the grinding roller (or the equivalent of the grinding roller grinding parts), grinding roll along the horizontal circular locus motion on the disc, is applied in the vertical .

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The cost in the vertical roller mill Reginalemoigne

The look of LUM ultrafine vertical roller mill signifies a single step forward in the grinding organization cobble vertical roller mill is principally broadly utilized in the medium and fine grinding of a myriad of really hard and extremely challenging ore, by way of example cement, refractories, bauxite, carborundum and glass raw Roller [.]

Working Of Vertical Raw Mill

Working Principle Of Vertical Raw Mill Working. working principle of vertical raw mill working crec. working vertical raw mill artsclubinstitute. working principle of vertical raw mill. gebr pfeiffer semvrmill working principle the solution to your problem in the cement industry, mvr roller mills .

jurnal vertical roller mill cement industry pdf

vertical roller mill Cement industry news from Global Cement. Egypt: Helwan Cement has ordered a vertical roller mill from Gebr Pfeiffer to grind coal at one of its cement plants in Egypt Delivery of the coal mill is scheduled . Inquiry; vertical roller mill for cement plant greenshireniralain

working rule of vertical roller mill

Working Law Of Vertical Roller Mill speeltuinlauradorpnl. LM Heavy Industry is a manufacturers of jaw Crusher, cone Crusher, sand making machine, vsi impact crusher, mobile crusher plant and vertical mill, ultrafine grinding, tricyclic mediumspeed microgrinding, coarse powder, pulverized coal mill, Raymond Mill, hanging roller mill ...

photograph of vertical mill gearbox

MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of . flender vertical mill gearbox km Traduire cette page. photograph of vertical mill gearbox LAW COLLEGE. Rugged, yet sophisticated. Perfect crusher drive How vertical mills perform fine .

vertical roller mill working

Four LOESCHE Vertical Roller Mills for Turkey | Loesche. LOESCHE is able to benefit from the growth in the Turkish cement industry. LOESCHE is contributing four of its highlymodern vertical roller mills to the new cement plant of the German technology firm AUNDE in the Turkish region of Soma: one mill for grinding up to 350 tonnes of raw material per hour for cement manufacture, one mill for ...

Is the cement production ball milled or ground? | Scramble ...

Apr 17, 2019· Vertical roller mills and ball mills are the main milling equipments that are widely discussed in cement production lines, but the electricity consumption of grinding equipment during grinding can account for 65% to 75% of the total electricity consumption of cement production, plus The demand for energy saving and emission reduction is becoming more and more strict, and the grinding .

Latest Posts

- تستخدم آلة طحن للبيع في ahmedabad

- digunakan كسارة باتو إلى ديوكوال

- سحق الخرسانة للبيع

- آلات التعدين كسارة الحجر شنغهاي

- كسارة الحجر الساخن بيع

- خطوات معالجة خام الذهب

- النحاس الذهب الخام مصنع لتجهيز

- تصنيع كسارة الحجر الصغيرة

- قائمة المعدات اللازمة للمحاجر

- التنقيب عن الذهب لوازم وعاء knudsen

- 5 12 القياسية مخروط محطم السودان

- تكلفة آلة طحن الكوارتز

- آلة التعدين على نطاق صغير في مصر

- الصابورة محطة كسارة للبيع

- والدولوميت خام كسارة

- cup mill for solid material grinding

- jaw crushers usa

- sand and gravel screening machine

- suppliers of chromite sand from south arica

- how to make rubber conveyor sheet stone crusher machine

- used concrete grinding polishing machines for sale

- b 2200 cone crusher parts

- small sand crushing m c

- conveyor inspection form and checklist

- carpco wet magnetic separators mining

- bergetar prinsip layar

- fintec f technical manual

- sbm mtm160

- used gold ore impact crusher for sale in angola jul

- silica sand wet screening