apron conveyor design pdf

ASCERTAINING THE METHODOLOGY FOR APRON FEEDERS .

The calculation of the AF is similar to that of the apron conveyors, but there are some peculiarities. The large size of material lumps is the cause for the increase of the width of the aprons and the height of the skirts. The presence of fixed skirts cause additional resistances due to skirt friction. The presence

TSUBAKI ENGINEERING CHAIN DIVISION .

TSUBAKI ENGINEERING CHAIN DIVISION ENGINEERING CLASS CHAINS Contents Page ... ROLLER CONVEYOR CHAIN ATTACHMENTS A21 ~ A34 APRON CONVEYORS A35 ~ A42 ROLLER CONVEYOR CHAIN SELECTION GUIDELINES A43 ~ A52 STEEL BUSHED CHAINS A53 ~ A60 ... Note: Dimensions are subject to change. Contact Union Chain to obtain certified prints for design ...

Maintenance and Troubleshooting of CONVEYORS AND .

TROUBLESHOOTING • Transfer chutes theory • Laser scanning applications • Best practice design • Boosting flow • Troubleshooting chutes • Spillage and buildup • The awkward marriage of conveyor and chutes Practical Exercise FEEDERS MAINTENANCE AND TROUBLESHOOTING • Belt, apron, screw and other feeders • Optimum draw down

Apron Feeder Design Calculation Troubleshooting

Basic Apron Feeder Design Calculations If you would like more information, please fill out our Apron Feeder Design Calculations Form and we will do our best to offer our suggestions Fill in application either in Metric or Imperial system.

TRANSFER POINT PRODUCTS Martin Eng

Escape of materials from conveyors is an everyday occurrence. It occurs in the forms of spillage and leakage from transfer points or carryback that adheres to the belt past the discharge point and drops off along the conveyor return. It also occurs in the form of airborne dust that is carried off and settles on structures, equipment and the ground.

USA Apron conveyor Google Patents

It is the object of the invention to eliminate the abovementioned disadvantages of the apron conveyor through a design which copes with stresses better.

IS 71555 (1990): Code of recommended practice for ...

Apron conveyor/feeder essentially consist of a drive frame, a drive, takeup, sprockets and pans fixed to chains which form the main pulling members. The pulling chains in mesh with the ... ( Design, Com missioning and Entry into Service ) Proper levelling of foundation and align ment of head and tails sections and intermediate ...

WVA Manufacturing, LLC Alloy Facility Box 158, Alloy ...

Design Capacity or Nominal Capacity or Allowable Limits Control Device ... Unloading Bin #1 to Apron Conveyor #1 Unloading Bin #2 to Apron Conveyor #2 Apron Conveyors #1 and #2 to 48" Pocket Belt #1 48" Pocket Belt #1 to 36" By Pass Conveyor and Inclined Screen

Hopper Discharge Devices Otto von Guericke University ...

a) Rubber belt conveyor without guide skirt b) Apron belt conveyor with guide skirt c) Sceleton flight conveyor (Redler) 2. Time dependent filling height H Fill, vertical stress v and horizontal force F h 3. Vertical stress vG as function of displacement of discharge device z at filling Tangential Force of Discharge Devices H Füll H Füll

Rex apron conveyors and feeders are performing around the world. Rex apron conveyors and feeders combine the most advanced design with a complete selection to meet all capacity requirements and conveyor profiles. Rex conveyors and feeders now available with patented adiustable takeup. Rex MD (multiple discharge) pan conveyor now available.

Crusher Apron Process

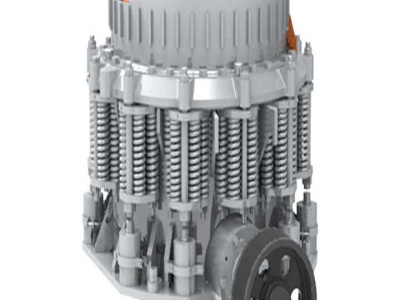

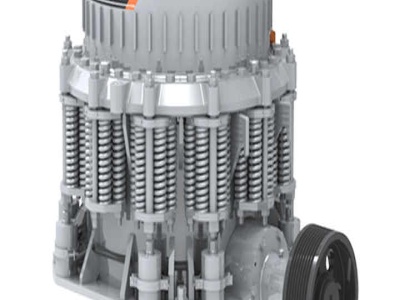

apron feeder,apron feeder design crusherschina. Apron feeder is rugged and dependable to receive and control the flow from bins and hoppers, then feed bulk materials to crushers, belt conveyors and other related mining machinery.

The Technical Dimensioning of the Conveyor Chain

According to the load distribution on the conveyor chain, a difference is to be made between point, individual and linear loading. lf the load is concentrated on a reduced area, the chain pins and rollers have to be recalculated concerning deflexion and pressure, respectively, when dimensioning the .

DESIGN PROCEDURE OF OVERHEAD MONORAIL FOR .

DESIGN PROCEDURE OF OVERHEAD MONORAIL FOR MATERIAL HANDLING SYSTEM FOR FOOD PROCESSING INDUSTRY A D Anjikar 1* and C C Handa *Corresponding Author:A D Anjikar, akshyaanjikar Handling of raw material, semi finished, finished product and other material is ever concern and cost in an industry.

HOPPER DISCHARGE SYSTEMS

Fig. 1 The special design of the Drag Chain Conveyor type TKF, in this example used for discharge of raw coal, allows to build the receiving hopper with a relatively small depth. Fig. 2 shows an alternative featuring an Armoured Chain Conveyor type PKF, with low construction height and tight connection to .

Airport Planning and Terminal Design Secretaría de la CLAC

Airport Planning and Terminal Design ˘ ˇˇ ˆ ... apron for future changes in ... 913 April 2007 3. Transporter Easy compatibility of terminal/ apron geometry and future aircraft design development Ease of aircraft manoeuvrability Ease of expansion capability for aircraft stands

PowerPoint Presentation

Advantages. Constantly designed for accuracy and reliability Low maintenance, easy belt change The measuring roller is placed directly on two load cells.

Airport Design and Engineering Standards – Airports

This page provides a quick reference to engineering, design, and construction standards for various airportrelated equipment, facilities, and structures. Visit our Series 150 Advisory Circular Library for a complete listing of current advisory circulars ...

IS 8599 (1977): Recommendations for selection of apron ...

Apron conveyors usually operate at slow speeds without any appreciable vibration and as such minimum lump breakage, 3. Construction Apron conveyors consist primarily of a series of overlapping steel pans or buckets carried on two or more endless strands of conveyor chains.

design of apron

The Symbolism and Design of the Masonic Apron. THE SYMBOLISM AND DESIGN OF THE MASONIC APRON with compliments of the Victorian Lodge of Research No 218, UGLV . Delivered in the Lodge by W. Bro. Hudspeth, PM, AMIE Australia on June 24, 1949 . The Apron is not a modern invention, in fact it is the most ancient of all garments.

How industrial plants benefit from apron feeder magnetic ...

How industrial plants benefit from apron feeder magnetic separators by Timothy G. Shuttleworth and Carlos Stipicic Magnetic Separators ... ed conveyors that feed a deep bed of ore from a bulk holding location (a bunker) as a controlled ... their design and engineering is essential.

Cement Conveyors

Cement Conveyors – When Being Tough Isn't Enough. Part of the reason for that is our commitment to making durable machines that can withstand the challenging conditions present during cement manufacturing. We've developed proven methods for making cement conveyors and clinker conveyors impervious to extreme temperatures, serious abrasion and powerful corrosives.

Apron Chains Pans

Aprons are used in conveyors and feeders where the most difficult operating conditions are present. The rollers provide lower operating friction, increasing chain life and reducing conveyor design requirements. OPERATION Apron conveyors are best suited for slow or moderatespeed applications. Maximum chain speed depends upon size of sprockets.

IS 71555 (1990): Code of recommended practice for ...

Apron conveyor/feeder essentially consist of a drive frame, a drive, takeup, sprockets and pans fixed to chains which form the main pulling members. The pulling chains in mesh with the ... ( Design, Com missioning and Entry into Service ) Proper levelling of foundation and align ment of head and tails sections and intermediate ...

Conveyors

built over 100+ conveyors from flat slider bed, trough idler or steel apron belts for industrial facilities. We manufacture top of the line material handling conveyors to make your process more efficient and reliable. Custom conveyor design per the customer's direction is welcome. Our designs consider maintenance access

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals, Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum.

Latest Posts

- مطاحن ذهب للبيع السودان

- المواصفات الكاملة لنظام ناقل الحزام

- آلة طحن الحجر 100 250 شبكة

- سعر وحدة كسارة الحجارة في المغرب

- سحق حجم الجسيمات الفحم

- خطة عمل محجر الحجر في ولاية كيرالا

- الكاولين آلة مسحوق الطين

- موردو الحجر الجيري في مصر

- كسارة hp 700 للبيع

- بناء وتجهيز خام الحديد

- شبكة معدنية تهتز شبكة سلكية خام

- تستخدم الكسارات ومحاجر للبيع

- ميزة كسارات المحمول التعدين

- آلة طحن وسحق الحجارة وفاق للبيع الصين

- الأرقام التسلسلية مطحنة ريمون

- carbide composition rods made in china

- iron ore processing plant equipment in iron ore processing

- gold ore mobile crusher price in indonessia

- three facts sedimentary rocks

- process mining gold

- coal crushing sell

- x6140 milling machine universal

- business thank you mail to client for exhibition visit

- earth embankments agriculture

- jaw crusher power considerations

- changing worn out parts in the cement plant raw mill

- s crusher cross sectional view

- agregat menghancurkan plantwanted

- crusher applications project on granite waste to sand

- jaw crusher calculation indonesia mine quarry