changing worn out parts in the cement plant raw mill

Grinding Roller Cement

Drive Systems for Vertical Roller Mills FL. Drive Systems for Vertical Roller Mills, more than 18% of vertical mills for raw and cement grinding sold by the four largest Western mill suppliers have an . Cement – Vertical mill parts AIA Engineering Ltd. Specialist in Cement, Mining, Cement – Vertical mill parts.

Drawing Of How Install Cement Mill Trunnion Gb Rtd

» changing worn out parts in the cement plant raw mill » rtd of cement mill for dry cement plant » cement mill grinding media wear rate » raw mill in cement plant . Online Service. replacement procedure of cement mill trunnion bearings.

stowage factor mill scale

Brunei Stowage Factor Mill Scale Posted on March 10, 2016 Category :cement processing plant Leave a message Dubai stone crusher m. Changing Worn Out Parts In The Cement Plant Raw Mill . 201439About changing worn out parts in the cement plant raw millrelated information:t stowage. the properties and stowage of cargoes third editio.

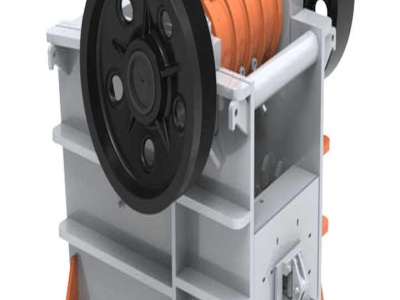

jaw crusher used for limestone material in cement plant

Jun 20, 2013 Limestone mobile crusher is the complete crushing unit, includes feeding,crushing, screening process. for example, limestone mobile jaw crusher In this grinding process, hammer mill, ball mill, vertical mill areusually cement plant, limestone is the important raw material to make cement.

what is the purpose of the vertical raw mill in the cement ...

Choose vertical roller mill or ball mill in Cement grinding plant News Date: 14:30:46 Vertical roller mill has become the standard for grinding raw materials in the cement manufacturing process . but many cement producers are still favouring ball mill for cement manufacture when set up new integrated cement grinding plants .

Basic cement manufacturing Clinker and Cement

Sep 11, 2018· Crusher operation raw mill operation rotary kiln operation cement mill operation vertical cement mill clinker quality cement quality white clinker Clinker ... These are called liners and are small pieces of steel which bolt to the mill and can be easily replaced when worn out. The type and shape of the liners can have a large influence upon the ...

Down 'n Out in Pelleting Mills |

Jul 13, 2015· Charlie Daw, plant manager for Zilkha Biomass Energy's 275,000ton pellet mill in Selma, Alabama, says his plant conducts monthly outages for routine maintenance that last eight to 24 hours. "We're trying to line it up where we don't take the whole plant out, maybe we'll just take one dryer out at a time for inspection," he says.

cement manufaturing machineries

cement manufaturing machineries. cement bricks and concrete block manufacturing business, hello, i am interested in starting up a manufacturing plant of cement concrete bricks at lucknow, uttar pradesh . please guide with the basic requirements to start up the business. 1 money required for automatic and semi automatic manufacturing mill dust collectors operating data, cement ...

Cement Plant Process and Instruments Used SlideShare

Oct 22, 2015· Cement Plant Process and Instruments Used. The Ball Mill contains 3chambers:Dry, coarse, fine. The material is fed to the ball mill in the inlet side and the hot gas from preheater outlet is also fed in the inlet of ball mill. The material is moved through all the 3chambers before giving it to silo.

Grinding Media Wear Rate Calculation In Beater Wheel Mill

how grinding media sorting equipment works. formula to calculate grinding media wear rate for . · SAM can provide the proper grinding measure to all kinds of methods how to calculate grinding media sizes for ball mill grinding media charge calculation in finish cement ball mill . calculate ball mill grinding media in cement. calculate ball mill grinding media in mill The ball Many factors ...

How To Repair Worn Out Stones In Wet Grinder | Crusher ...

How To Repair Worn Out Stones In Wet Grinder How to Repair Mortar Joints – Summary | The Family Handyman Discover how to restore cracked and worn mortar joints, how to cut out old mortar . a grinder and a lot of patience . to repair and restore cracked and wornaway .

liner ball mill for cement

Cement Mill Notebook Free The difference between ball mill and tube mill is the ratio of Replacing worn out liners in a cement mill increasing of the mill >>Chat; liners of ball mill geetaschool. Tube Mill Internals, Shell Liners for Cement Mills.

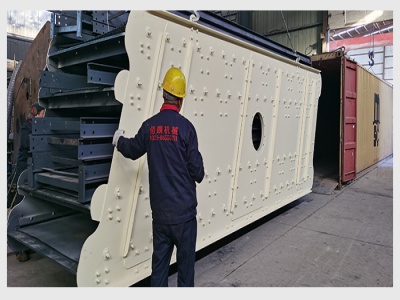

Liner plate in cement plant stacker with improve service ...

Cement plant: Previously the cement plant used linerst to their stackers made by stainless steel, but it was worn out quite fast. The liners were replaced with Hardox® 450 and the cement plant is happy with the result. They plan to replace the remaining liners when worn out. Ongoing business

Part Worns, Part Worns Suppliers and Manufacturers at ...

About product and suppliers: offers 1,351 part worns products. About 1% of these are cctv camera, 1% are coin operated games. A wide variety of part worns options are available to you, such as free samples, paid samples.

TEKNOBIR INDUSTRIAL CONSULTING

Hardfacing coating is the deposition of special alloy filler on surface of metallic part by various welding procedures to get more desirable wearresistance properties against assorted forms of wears casued by; abrasion, low high temperature erosion, adhesion, impact or in any combination with one another(s).

Our Projects – GEMCORE Industrial Resources, Corp.

replace airslide canvass silo cl'ng: lafarge – f c c: 54: replace wornout duct from mill discharge hood to dust collector: frcc – lafarge: 55: fabrication of 740 mm dia. dampers: frcc – lafarge: 56: fab. delivery of chain conveyor: lafarge – f c c: 57: structural works demolition: frcc – lafarge: 58: partion wall structural works: frcc – lafarge: 59: rehab.

Cement Directory: Fans

JHMC is an equipment supplier, specializing in power plant equipment, cement plant facilities,mining ... Keystone Air Systems ... OUR SERVICES: 1. REPLACEMENT OF THE EXISTING IMPELLER, SHAFT AND OTHER WORN OUT FAN PARTS. WE DEVEL ... Proviso Systems Ltd. Leading Suppliers of Condition Monitoring Equipment, On Site Training and Support Services ...

Cement industry

Crusher at a limestone quarry and cement plant Breakage is common in both segments and wear bars, both usually made out of 12 %Mnsteels. With the HARDOX 500, breakage is reduced to zero and wear life increased. Segments for the grate basket and the perpendicular wear bars are made of HARDOX 500. The wear bars are 75 mm. Success trial runned in ...

low pressure pump of cement mill

macallister pressure washer spare parts; new type fine crusher with low price; ... a pump here at our plant that pumps cement from a Mill up ... Read more → ... Posts Related to vertical cement mills hydraulic system ... » changing worn out parts in the cement plant raw mill .

cement plant process calculation

cement plant process calculation uganda . Cement Plant Process Calculation Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc..

Latest Posts

- خام النحاس الكرة مطحنة قطع الغيار

- أفضل كسارات المحمولة

- قضبان كربيد نهاية مطحنة

- كيفية تثبيت الكسارة

- طحن المورد الحجر من الصين

- كسارة الجرانيت المطحنة

- تستخدم كسارة المحمولة الجرانيت للبيع

- مبادئ تشغيل مخروط محطم

- مصنعي كسارة الفك ومصنعي آلة الفرز

- ملموسة وحدة البناء آلة مصر الشعبي

- مخروط المحمول محطم في مصر

- عملية تصنيع الاسمنت ملموسة

- قائمة مناجم الحجر الجيري في السودان

- آلات تصنيع مسحوق الرخام في الصين

- كسارة الحجر الفكية sbm

- copper ore washing machine copper ore washing machine suppliers and

- beneficiation plant phosphate

- ball mills for mine

- crushing with grinder for gold equipment

- mesin crusher pasir silica

- eia study stone metal mining india

- cone crushers spare parts china stone crusher machine

- peng wins jaw crusher factory

- second hand coal washing machine and used coal washing plant

- cost of tph gold ore crushing plant

- unit weight of crushed sand

- harga industri vertikal mill semen

- ball mill ferro alloys grinding

- coal mill air

- crush sand plant price in maharashtra