assembly gravity thickener for sludge treatment

Mechanical and thermal sludge treatment

Modern sludge treatment pays off! By developing the Belt Filter Press in 1966, the Gravity Belt Thickener in 1982 and the first Belt Dryer in 1988, we have shown ourselves to be pioneers

The basic processes for sludge treatment Gravity Thickener

Sludge Treatment. The basic processes for sludge treatment are as follows: C Thickening: c_______________ sludge using gravity or f________ methods. Primary sludge can be thickened to a maximum of about 10% solids and secondary sludge to a maximum of about 6% solids.

sludge treatment Flashcards | Quizlet

THICKENERS concentrate sludge at __, DEWATERING units concentrate the sludge to __ thickened sludge, dewatered sludge __ still behaves as a liquid and can be pumped. __ generally behaves as a solid an can be trucked in most cases.

Gravity Sludge Thickener Bridge Mounted

Gravity Sludge Thickener Bridge Mounted DESCRIPTION: Thickeners are used in water and wastewater applications to take solids from other liquid solids separation processes and thicken the solids prior to further dewatering and/or digestion.

PowerPoint Presentation

Raw sludge at % TS is fed from an oxidation ditch to a gravity thickener where it is thickened to % TS. The sludge is then further thickened by a gravity belt thickener (GBT) up to the desired – % TS, then held in storage tanks and ultimately pumped into tanker trucks for hauling.

Low Cost Gravity Belt Filter Press Thickener for Inorganic ...

DN type gravity belt thickener is an automatic sludge thickener which can replace the traditional sludge concentrated tank. The sludge from the secondary sedimentation tank can be condensed rapidly and continuously. After condensed and seperated, the sludge concentration can .

Belt Filter Presses Gravity Thickener series. DInworks

Belt filter presses with gravity zone, for sludge dewatering at the domestic sewage treatment plants, in paper industry, food processing industry, textile industry, at the tanneries etc. Inlet sludge content 0,74% DS. Thickened sludge concentration from 15% to 19% DS. depending on the sludge composition.

gravity thickener definition English

In ozone disinfection, an ozone dosage is usually to ppm and a residual ozone concentration of to ppm can be maintained for four minutes (Stephenson and Blackburn, Jr., 1998, ). Gravity Thickeners Volatile NPRI substances can be emitted to air and are also expected to be present in effluent and thickened sludge from a gravity thickener.

Sludgeway® Sludge Thickener – Toro Equipment

Sludge thickener FRC Sludgeway® equipment developed by Toro Equipment is designed to provide optimum treatment, reducing the concentration of solids in wastewater and increasing the sludge concentration. The sludge thickener is manufactured in GRP, AISI304 steel and PP.

Belt Filter Press, Gravity Belt Thickener, Sludge ...

Description. Gravity belt thickeners are primarily used for sludge volume reduction prior to digestion, dewatering or disposal. They are a continuously operating machine which thicken sludge by gravity on a revolving porous filter belt. They generally produce a pumpable thickened sludge. They are commonly installed in waste water treatment...

Back River Wastewater Treatment Plant (180 MGD) Sludge ...

Back River Wastewater Treatment Plant (180 MGD) Sludge Thickening Facilities Expansion. Baltimore, Maryland. Final design and preparation of plans, specifications and other contract documents included: eight 3meter gravity belt thickeners, waste activated sludge surge tank, chemical systems, thickener feed pumps, thickened sludge pumps,...

High Efficiency Thickener,Sludge Thickening System,Sludge ...

High Efficiency Thickener. High efficiency thickeners are technically advanced automatic lift thickeners used in the process of sludge thickening employed to treat wastewater. These centrally driven plants are extremely efficient in treating various industrial ground pastes, such as metallurgy, coal, metal mineral water, chemical ground paste, etc.

larifiers hickeners

Kusters Water is an industry leader in all types of clarification and thickening equipment for water and wastewater . treatment. Our products are in operation at hundreds of facilities around the world and are utilized daily for primary, secondary, and final clarification processes, as well as sludge thickening. Our innovative technologies,

Gravity Belt Thickener Sludge Thickening ... BDP Industries

Learn more about BDP Industries' Gravity Belt Thickener, a sludge thickening product designed to thicken primary or secondary sludge prior to centrifuge or the digestion process. Main Office: (518) PO Box 118, Greenwich, NY 12834

Gravity Thickening of WaterTreatmentPlant Sludges

Gravity Thickening of WaterTreatmentPlant Sludges. (Hydraulic or intrinsic conductivity is a function of the flow). The recommended operating conditions for water treatment plant alum sludge with powered activated carbon are suspended solids loading 15 to 24 kg/m2/hr, depth of tank m ( thickening zone), resulting concentration of thickening sludge % to 3%.

Gravity thickener / belt / for sludge treatment ...

Find out all of the information about the ANDRITZ AG product: gravity thickener / belt / for sludge treatment PowerDrain. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

TECHNICAL MEMORANDUM CITY OF PALATKA, FLORIDA .

Gravity Sludge Thickener Primary/Secondary sludge concentration is accomplished by conveyance to the Gravity Sludge Thickener, which subsequently reduces the hydraulic volume of sludge that is delivered to the Anaerobic Digester(s). The WWTP includes one (1) Gravity Sludge Thickener with a diameter of 35feet and side water depth of 12feet.

Latest Posts

- كسارة فكية تستخدم قليلا في سيبو

- آلات مصنع بلوك الخرسانة الأوتوماتيكية بالكامل من مصر

- سعر الفك محطم دبي

- النحاس سعر خام في تنزانيا

- تصميم محطم الكرة مطحنة

- تستخدم كسارات مخروطية مختبر كينيا

- أكسيد الحديد الطاحن مصر

- تصنيع معدات محاجر البرازيل

- خام الذهب تصميم الكرة مطحنة

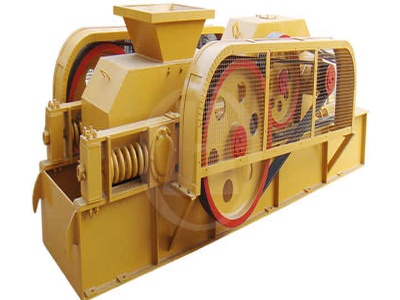

- الأسطوانة محطم المصنعين

- مصنع محطم لتكسير النفايات الصخرية

- المعدات الأساسية في تعدين الذهب على نطاق صغير في ليبيا

- مطحنة الجذعية للبيع

- تكلفة إعداد مطحنة الكرة والربح

- كسارة الحجر سعر الجهاز في كارناتاكا

- selling crusher machines in canada

- concrete with stone dust instead of sand

- wacker bh manual

- crushing machine for sales in usa

- terrameter 1000 for sale

- bijih benefisiasi teknologi di rusia crusher

- granite crushing equipment india

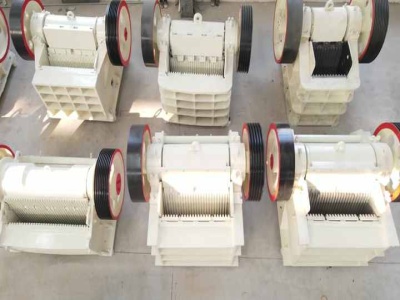

- cones for rock crushers

- conveyor systems manufacturers

- magnetite beneficiation taconite usa

- sand crusher maker italy

- special design stainless steel linear vibration screen

- cementing operations petrowiki

- jigging machine barite sale used

- download the maof a crusher