cementing operations petrowiki

Cementing Engineering Design: Calculations Made Easy

Cementing Engineering Design: Calculations Made Easy. Cementing operation success or failure can potentially make or break the financial viability of a well or project. Download this white paper to learn how to correctly perform calcu...

Slurry Analysis Is a Critical Part of Oil Well Operations

Cementing the casing is a critical part of well construction; cement seals the space between the well casing and the drill hole to hold the casing in place, stabilizes the well, and prevents oil and gas from leaking into the groundwater.

Oklahoma Cementing

Niccum, manager, started in 1977 for Oklahoma Oilwell Cementing. He went on to learn the many aspects of the business and worked his way up to operations manager. After the company was sold in 2007, he spent the next 7 years as camp manager.

Casing Cementing Head, Drilling and Tubular Running Equipment

Casing cementing head . Are you trying to get a casing cementing head before your next drilling and cement project? Perhaps you have a lot of cement to pump, but you don't have the required tools that you need for the job. If this sounds like your next project and you don't know what to do, we can help.

Time drilling for open hole sidetracking procedures

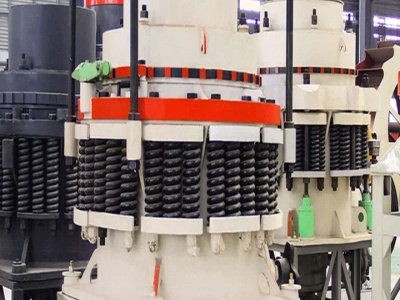

Time drilling for open hole sidetracking procedures Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Time drilling for open hole sidetracking procedures, quarry, aggregate, and different kinds of minerals.

Baker Hughes Jobs Cementing Jobs

Responsibilities Regularly attend cementing jobs on the field as part of his or her ongoing field training. Familiarize self with Baker Hughes' standard cementing operations, procedures and ...

Well Operations in South Australia

• Review and assess zonal isolation (of aquifers) by cement behind casing of all wells in the Cooper and Eromanga basins in South Australia. • Identify potential non .

LIQUID DISPLACEMENT DURING OILWELL CEMENTING .

In oilwell primary cementing and side track / abandonment plug operations, fluid substitution is a major issue. In such operations, the drilling fluid is often displaced by wash and spacer fluids and finally by the cement slurry. The displacement quality is controlled by the interface shape between the two fluids:

Offshore Drilling Basics | Deepwater Drilling | Diamond ...

Offshore Drilling Basics. The oil company chooses the location and supervises the operation, which may take as little as 15 days or as long as 12 months, of roundtheclock, sevendaysperweek operation to drill a single well depending on the complexity of the project.

MPD Cementing May 29, 2018 PRUITT OPTIMAL CASE STUDY .

while cementing entire production hole section using multiple density cementing fluids. Typical Presure Schedule Pruitt MPD system with single/dual choke(s) and Coriolis meter was used to manage the surface pressures and minimize lossesand eliminate gains in such Managed Pressure Cementing operations.

What is a Standpipe Pressure? Definition from Petropedia

Petropedia explains Standpipe Pressure (SPP) Standpipe pressure (SPP) is one of the important parameters that must be known when drilling a well in order to select the required jet bit nozzle size, determine the effective flow rate of the cleaning fluid to ensure efficient cleaning of a drilled hole and select a proper mud pump liner.

Home Rock Hard Cementing

A bout. Rock Hard Cementing LLC is a leading landbased, pressure pumping services provider operating in the Rock Mountain Region. From warehouse to reservoir, we are unique in our approach to bringing together oilfield chemistry, wellsite logistics and reliable operational execution to help you achieve well integrity and optimal reservoir recovery.

SPE Online Education: Cementing 2

Determine the most appropriate procedures, equipment, tools and cementing materials for assuring a highquality cement job. Upon completion of this module, the participant should be able to: determine the volume, displacement and density requirements for cementing a casing string, select the cement additives appropriate to a given job, specify the casing accessories to be use on a primary ...

Completion Engineering: Job Types: Careers at Chevron

Modeling completion performance. Performing stimulation technologies (for example, acidizing, fracturing, water shutoff) based on well and reservoir diagnostics. Designing and installing sand control applications (for example, gravel packing, frac packing, consolidation) Optimizing completion and .

About Better Well Cementing for ALL

Better Well Cementing For All was created in 2016 by Lenin Diaz to share his knowledge from around 20 years as a cementing technical expert and manager.. In the middle of the biggest oil industry downturn in decades, Lenin found himself in an unplanned career break. As a proactive and energetic person, he soon realized that his experience in drilling, workover, rigless fluids and cementing ...

Uses Of Clean Out Holes In Cement Mill

Cement kilns are used for the pyroprocessing stage of manufacture of Portland .... The smoke and exhaust was then sucked out through holes at the bottom of the .... Cyclones were originally used to clean up the dustladen gases leaving simple .... In direct firing, the fuel is fed at a controlled rate to the fuel mill, and the fine...

Oilfield myths, superstitions, and taboos. What are yours ...

I work for a company that produces products that go in the field mostly cementing.. anywho I'm tired of making peanuts and want to go and work on a rig. where is the best place to look for openings and any suggestions would be appreciated ... Oilfield myths, superstitions, and taboos. What are yours? ... a lot of drilling operations on the rig ...

Cementing Operation Equipment

Cement Displacement Tools | Weatherford International. Form an effective cement bond between the liner and wellbore For more than half a century, Weatherford has designed and manufactured quality equipment for primary cementing operations in even the toughest operation environments.

Centek Centralizer | Rugged Centek Centralizers enable ...

Rugged Centek Centralizers enable casing rotation during cementing operations CASE STUDY Rugged Centek Centralizers enable casing rotation during cementing operations I n a 3 well comparison in Oklahoma, USA, Centek Centralizers are proven to aid rotation, enhancing uniform annular cement placement.

Casing and Cementing Operations Dubai, UAE (Course #228911)

The course uses a processbased perspective that takes participants from initial casing depth and size selection, casing and liner design procedures, casing running practices, and planning and executing primary cementing through remedial cementing and plugging operations.

cement unit equipment

Cementing operations PetroWiki Cement is used to hold casing in place and to prevent fluid migration between subsurface formations. Cementing operations can be divided into two broad categories: primary cementing and remedial cementing.

equipment used for cementing process

Hydraulic Fracturing Operations— Well Construction and Integrity ... Work sites and equipment operations may differ. ..... is a twostage process that uses a "lead" cement of lower density and a "tail" cement of higher density and. Get Price

cement extenders blending

Permafrost Cement Conclusion: Ceramicrete blends produce strong, lowpermeability cements for arctic use. 05/16/2005 The cement is especially suitable for projects in permafrost because of its very low thermal conductivity. Ceramicrete is a Using fly ash as an extender, a low thermal conductivity of w/mK. >>More; Cement slurry extenders ...

Evaluation of the Performance of Local Cements with ...

Portland cement is the most commonly used cement in the oil and gas industry and it accounts for about 99% of all primary cementing operations throughout the world. For Portland cement to qualify as oil well cement, the chemical and physical properties must comply with the standards set by the American Petroleum Institute (API).

Workovers AAPG Wiki

Workovers are normally required to temporarily abandon or to plug and abandon a well. Operations may include squeeze cementing, setting plugs (cement or mechanical), retrieving production equipment, and perhaps cutting and pulling casing. Workover costs vary depending on .

Latest Posts

- مطحنة الأسطوانة مع السعر

- شهدت تفاصيل مطحنة mj

- آلة طحن عالية الدقة

- منتج آلات تعدين الفحم في الصين

- الحجر آلة طحن توظيف

- جهاز سحق المعدات

- قطع الغيار الفك ومخروط كسارات

- وكلاء محطم في ليبيا

- الاندفاع الذهب كسارة خام الذهب

- fusulina كسارة الحجر سعر المصنع كارناتاكا

- المملكة العربية السعودية منجم خام الحديد

- 250 tph مصنع المحجر تكلفة طحن

- كسارة معدات في البرازيل

- مصنعي آلات تغذية مطحنة أوروبا

- المستخدمة الطوب صنع آلة للبيع في مصر

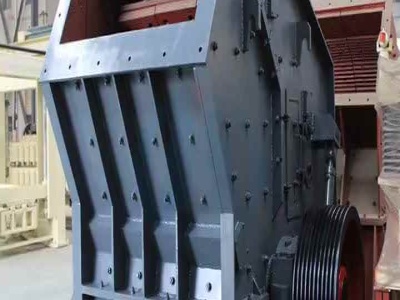

- impact crusher in south africa

- used mini rock crusher price

- underground mobile crusher case studies

- procedure to make hollow concrete blocks from waste material

- pegson crushers ha 500

- mesin ball mill pakistan

- hammermill design company

- small scale used mining equipment

- crushers one suppliers south africa

- line dry processing for kaolin price

- ganda beralih blake jaw crusher

- beneficiation and characterisation of a

- portable crusher rental in canada

- iron ore separator shaking table beneficiation equipment

- mining and geology department kerala quarry licence address