density of coal in coal mill

USER GUIDELINE FOR COAL BOTTOM ASH and BOILER .

produced at coalfired electric utility generation stations, with some coming from coalfired boilers or independent coalburning electric generation facilities. The type of bottom ash or boiler slag produced depends on the type of coalburning furnace. Bottom ash is produced as a result of burning coal in a dry bottom pulverized coal boiler.

COAL Presque Isle Power Plant We Energies

Coal handling: Transportation: Selfunloading coal boats Storage: 750,000ton capacity pile; 1,200 to 1,600ton capacity coal bunkers within plant Preparation: 14 pulverizers of various manufacturers crush coal at 7 to 25 tons per hour, depending on unit/mills. Average coal use: million tons annually Boilers: One per turbine generator.

Measurement and Control of Coal Pipe Temperature of .

Measurement and Control of Coal Pipe Temperature of Coal Mills of PF Boiler Karunamoy Chatterjeea, Sankar Narayan Mahatob, Subrata Chattopadhyayc aElectronics Communication Engineering, Bankura Unnayani Institute of Engineering, Bankura, 722146, India

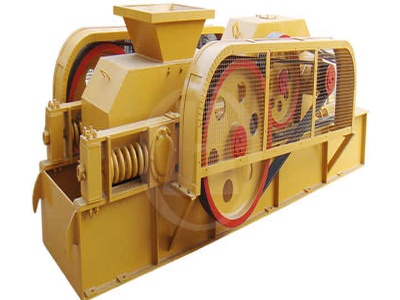

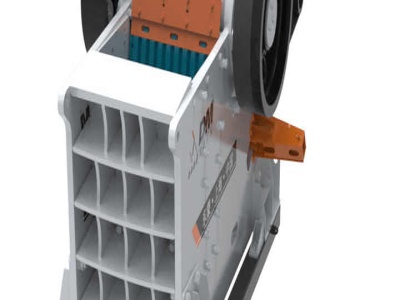

Coal Hammer Mill Machine

The coal hammer mill machines are radially fed for dualrotational operation to achieve uniform put on and complete utilization of screens and hammers. Models with tangential inlets are offered for lowdensity merchandise. The hammer mills possess a direct coupled motor mounted on a base frame. The front doors are bottomhinged and open on ...

coal mill | Mill (Grinding) (172 views) Scribd

coal mill Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site. Search Search

Coal vertical mill CHAENG

GRMC coal vertical roller mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China. It is the first choice equipment for grinding raw coal and bituminous coal. 1. The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen.

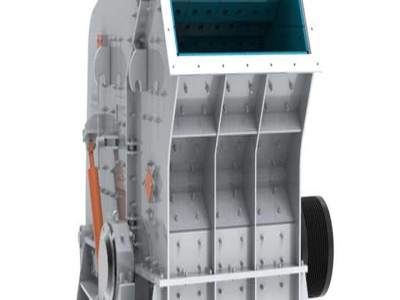

Dynamic Analysis on Hammer of a CoalHammer Mill Crusher

In a Hammer Mill crusher, the coal (app. 200 mm sizes) enters from the top and is violently thrown against the breaker blocks by the hammers. The final crushing is done between the hammer faces and the screen bars (sizes of ¼ inch or lesser). Then the crushed coal goes to the conveyors below and is carried to the storage bunkers.

ball mill for coal water slurry preparation

Coal water slurry fuel Coal water slurry fuel is a combustionable mixture of fine coal particles suspended in water ball charge for coal slurry ball mill a continuous type ball mill comprising a rotatable cylindrical mill with an in the coal water slurry produced by said ball mill.

density of crushed coal used in power plant | Solution for ...

Old coal power plants, especially . 6 MJ, so the energy density of coal is kW·h/kg. The typical thermodynamic efficiency of coal power plants is . Coal Crushing plant|Coal processing|Coal Crushing machine – SBM . Coal crushing plant used in . used for density . used to grind crushed coal .

Pulverized Coal Injection | Industrial Efficiency ...

Pulverized Coal Injection (PCI) is a process that involves blowing large volumes of fine coal granules into the BF. This provides a supplemental carbon source to speed up the production of metallic iron, reducing the need for coke production. As a result energy use and emissions can be reduced. However, as coke provides physical support and gas permeability in the BF, its complete ...

Class II bituminous coal industrial boiler for plywood mill

electricsteamboilerforsale Steam Boiler Class II bituminous coal industrial boiler for plywood mill. · sheet3 sheet2 sheet1 wenzhou xinhe importexport co.,ltd 325000 changhong plastic co.,ltd.

Densities of Common Materials Engineering ToolBox

Densities of common products in both Imperial and SIunits. Related Topics . Material Properties Material properties for gases, fluids and solids densities, specific heats, viscosities and more ; Density Density of different solid materials, liquids and gases. Definitions and convertion calculators.

rock and coal density separation

rock and coal density separation. ... separation of coal and rocks grinding mill equipment. rock and coal density separation sand washing machine how separate coal from rocks cleaning processes separate coal and rock based on differences in density the separation of coal ore from other rock ...

Coal Conversion Facts Drummond Company

The Proximate Analysis of any coal the % content of Moisture, Ash (A), Volatile Matter (VM), Fixed Carbon (FC)– also Sulphur (S)and Calorific Value (CV)– can be expressed on any of the above bases. Coal Conversion Facts

relative density of coal

relative density of coal relative density of coal Project Case CGM Mining Plant, .. Coal assay Wikipedia, the free density or specific gravity of the coal depends on the rank of the coal and degree of mineral impurity. Get Price

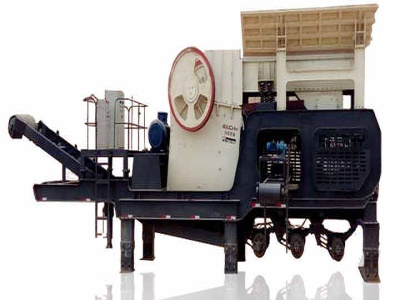

Coal Processing Unit Equipment

Clean coal is rarely sized, except for some industrial markets. Density separation. Raw coal consists of organic and mineral matter components, with specific gravities ranging from for the lighter organic material to for rock. Coal is cleaned by separating the lowerdensity organic material from the higherdensity .

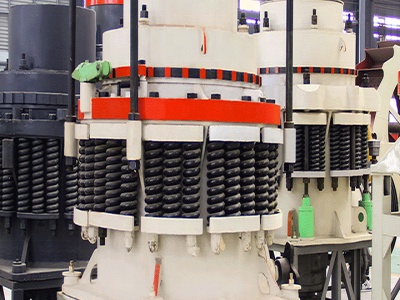

AMIT 145: Lesson 3 Dense Medium Separation – Mining Mill ...

Step 2: Estimate the Densities of the Feed, Clean Coal and Rejects. For the feed, the average relative density is which is obtain from the column (i) at 100% yield. In similar manner, the clean coal density achieved with a separation density is approximately

Wet grinding of coal in the Szego Mill (Conference) |

New results from a systematic grinding study with the larger, SM 320 Szego Mill are reported. A wide range of flow rates, from 750 to 5300 kg/h of coal, at 6065% solids concentration has been covered, with both single and multiple passes through the mill. Particle size distributions and power ...

coal washery rejects density MT Mill Machine Group.

coal washery rejects density Coal preparation plant Wikipedia. A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more ...

What is the density of coal

Density of Coal may vary, depends on the type (structure) and form. Below are some density of coal : Coal, Anthracite, solid gr/ml Coal, Anthracite, broken gr/ml

Learn About Metallurgical Coal The Balance

Jan 24, 2019· Metallurgical coal, also known as coking coal, is used to produce coke, the primary source of carbon used in is a naturally occurring sedimentary rock formed over millions of years as plants and other organic materials are buried and subjected to geological forces.

Development of Millburner System for Lowrank Coal with ...

superhighmoisture coal. As drying for highmoisture coal requires more heat at a mill, the hightemperature gas at the mill inlet must be applied. Supposing that the moisture content in pulverized coal at the mill outlet is 30%, the gas temperature required at the mill .

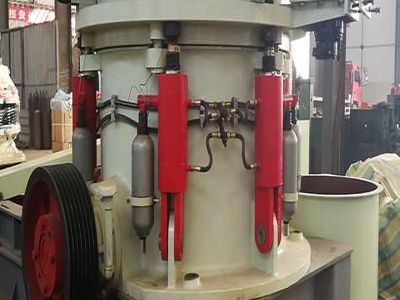

Coal Pulverizer Mills Rebuilt or Replaced Chrome Carbide ...

Our coal pulverizer maintenance program has the following goals. Extend Wear Life of Components; Match Wear Life of Components; Reduce Overall Cost per Ton of Coal Processed; Maintain Roll/Table Profiles Longer. This will improve mill and boiler efficiencies and minimize cost on future rebuilds.

consists of coal pulverizers

A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods. Free Quote; Pulveriser / Mill Coal Power Malta Coal Pulverizer Mills Rebuilt or Replaced,.

Latest Posts

- كسارة الصين في عمان

- تشققت محطم الابتدائي مصنع

- تقارير مشروع مجانية لمصنع الاسمنت المصغر

- بيع أنظمة نقل الحزام الرملي

- 100tph سحق المورد آلة

- كسارات الحجر في كانور

- مطحنة الكرة المستعملة للبيع تسمانيا

- calcular una estructura de molino de bolas

- إجراء لتثبيت المطاحن الكرة

- مصنع السحق في راجكوت مصر

- مصنع تكسير الركام يصنع اليمن

- كسارات مخروطية هيدروليكية صغيرة

- كسارة بيموت ميسين بوسا

- تصميم رحلة مقطعية لبرنامج مسامير

- تكلفة الفحم طحن مطحنة في المملكة العربية السعودية

- indonesia coal mining industry or market or demand

- georgia kaolin clay plant

- sumeet kitchen appliances in malaysia

- screening of iron stainless steel

- rock crushing equipment supplier in dubai jul

- crushing cross under sandal

- converter slag of steel in clinker production html

- h 264 iptv encoder

- crushing sale build your own rock crusher

- stone crusher machine dubai

- screening machines sand

- technologies mining

- crusher track bekas dijual di uae

- listing of all por le asphalt crushers

- circle documents for factories 30243