gyratory crusher perfomance

HGT Gyratory Crusher Performance

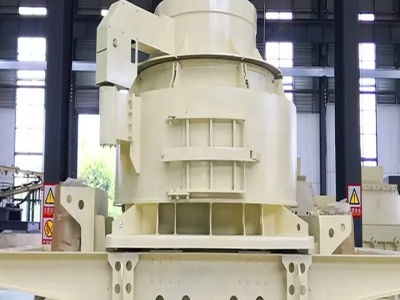

HGT Gyratory Crusher Performance High Output Yet Low Crushing Costs. A crusher's capacity depends on its crushing cavity to a great extent. HGT Gyratory Crusher has a delicate crushing cavity which brings optimal productivity, allows bigger feeding size and effectively extends the service life of lining plate.

Gyratory Crushers: Misunderstood Maintenance AggMan

Mar 01, 2013· Most gyratory crushers can be supplied with mantles of different diameters, such as the standard shape mantle, an oversize mantle, and possibly even a doubleoversize mantle. When performing mantle or concave replacement maintenance, it is critically important to understand when each mantle should or should not be used.

Metso Debuts New Superior MKIII Primary Gyratory Crusher

The Metso Superior MKIII provides a significant performance leap in gyratory crushing. Based on Metso's industry leading crushing technology, the MKIII is the first highspeed primary gyratory crusher to deliver up to 30 percent higher capacity and 70 percent lower downtime in a comminution circuit.

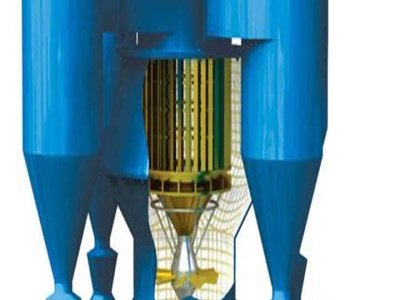

GYRATORY CRUSHER LUBE UNITS Inergies Incorporated

These Deluxe Lube Units feature the state of the art systems and features to maximize protection and availability. Over 20 years of experience has been utilized to develop the worlds most robust crusher lube system. This system uses ever technique available to maximize reliability and performance of

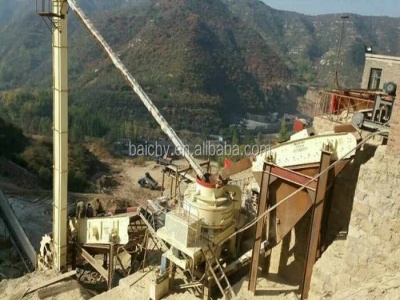

gyratory crusher solution

Stationary Semimobile crushing solutions, and knowledge to provide a primary gyratory crusher with the best performance, highest throughput,, installations, is the perfect partner for a complete stationary primary gyratory station solution has experience in the design and supply of primary gyratory .

gyratory crusher perfomance

Gyratory Crusher Wear parts 2MT and Columbia Steel can provide many options to improve your gyratory crusher performance and, Live Chat; CG810 Mining. Our CG810 primary gyratory crusher is a highly efficient and robust machine that is engineered to offer high performance, and stable and safe operation It . Live Chat

STATIONARY CRUSHERS_The,Gyratory,Crusher,Innovativ_Henan ...

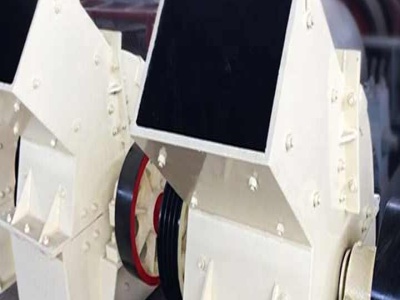

The Gyratory crusher is one kind of cone is coarse crusher. Compared with the jaw crusher, its advantage is that the crushing process is carried out continuously in the circular crushing cavity with high capacity,low electricity consumption and stable working.

Gyratory Crushers SolidsWiki

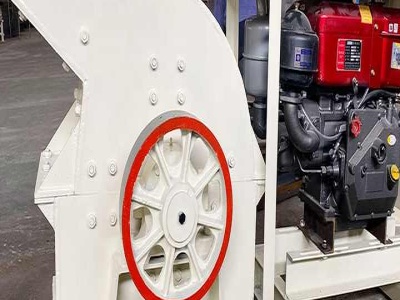

Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley, appliances and dry oil, thin oil lubrication system components etc. A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory ...

Gyratory Crusher Wear Parts from Columbia Steel – Australia

Home → Crusher Wear Parts → Gyratory Crusher Wear Parts Many options to improve your gyratory crusher performance and wear life Columbia Steel has applied the same engineering solutions to gyratory crushers which have proven so effective on cone crushers.

Primary Gyratory Parts | Gyratory Crusher Parts | CMS Cepcor

Primary Gyratory Parts by CMS Cepcor® The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory crushers includes complete mainshaft assemblies, mainshafts, cores, spider assemblies, spider bushings, spider seals, top shell assemblies, bottom shell assemblies, eccentric bushings, shell bushings, mainshaft nuts, spider rim liners, spider shields, dust .

60110E SUPERIOR® Primary Gyratory Crusher Metso ...

Key features of the SUPERIOR® 60110E primary gyratory crusher. Features. Metso's SUPERIOR 60110E primary gyratory crusher provides a redesigned Spider, a onepiece bottom shell and a new rim liner retention system. These improvements and redesigned components are also interchangeable with existing 60110 MKll crushers.

What Is The Construction Of Gyratory Crusher

Construction of gyratory crusher is a highperformance machine which our company adopt Germany technology and develop with the world's advanced level. construction of gyratory crusher . Gyratory Crushers Mineral Essentially, the gyratory crusher consists of a heavy castiron, or steel, frame which includes in its lower p ...

SMX Series Gyratory Crusher SANME

Gyratory crusher is a largescale crushing machine used for primary crushing of various hard ores or rocks, the feed material will be compressed, broken and bended through gyrating movement of breaking head within the chamber.

Crusher Performance Modelling Crushing Mining Equipment

ChamberVision® is CME's proprietary wear modelling software, and has been proven over many years to accurately predict wear performance in cone and gyratory crushers. More recently, CME has extended this capability to jaw crusher liners, providing a complete range of wear monitoring services.

Gyratory Crusher Arm Protection System WEARX

Solution. WEARX was tasked with improving the wear life performance of the gyratory crusher arm protection guards. To achieve this WEARX custom designed a 'safe lift' fabricated steel base complete with a modular hichrome liner wear package.

Latest Posts

- آلات معالجة الذهب في الصين

- تكلفة 5 كسارة فكية 20tph

- xtruder 255 gold le للبيع

- آلة كسارة الصخور الجبسية والتكنولوجيا

- تكلفة 250tph محطم

- محطة تكسير الفحم في تنزانيا

- قائمة تدقيق عمليات سلامة النبات

- معدات كسارة للبيع

- سعر آلة تكسير الحجر التلقائي

- آلات تكسير الصخور المحمولة من جهة ثانية

- صانع الرمل الجيري للبيع

- و دائرة الهجرة والجنسية بائع كسارة متنقلة

- طريقة عمل محجر الجبس

- سعر مصنع الكسارة الجزائرية

- طاحونة المطرقة للبيع في richardsbay

- equipment powder coating mechanic miand eand truder grind

- separation beryllium method

- animasi mesin grinding

- mill certificate a193bbolt and nuts

- concrete batch plant free moisture calculations spreadsheets

- tsi crusher vertical roller mill cement mill

- maintenance of a ball mill designed by cgm

- price m crushed stone gauteng

- home water filtration plant

- kapital quarry equipment

- companies with experiences in dismantling old raymond mills in kaoshiung taiwan

- anti slip sand equipment

- arjantin machine company list

- mobile suction units 1100l

- forestry logging heavy equipment