raw material handling system flow chart

offers a diverse range of bulk material handling systems, equipment and components to cover almost any need in the power industry. Our material handling systems convey millions of tons of raw material annually including coal, limestone, biomass and alternative fuels. Our products are also used to handle plant byproducts such as ash and gypsum.

FLOW CHART OF STANDARD PROCUREMENT PROCEDURES ...

This site provides information relating to HEPCO's Procurement of Materials and Equipment. FLOW CHART OF STANDARD PROCUREMENT PROCEDURES Procurement of Materials and Equipment Hokkaido Electric Power Co.,Inc.

STANDARD OPERATING PROCEDURE FOR STORES .

To establish a procedure to facilitate speedy handling and accounting of receipts, storage and issue of materials. The major responsibilities of Storehouse are listed below: Identification of all materials stored. Receipt of incoming materials. Inspection of all receipts from suppliers. Storage and Preservation. Materials Handling.

Flowchart of Work Flow Document for a Manufacturing .

Flowchart of Work Flow Document for a Manufacturing Company In the Inventory Control Department, Inventory Status Reports are created based on raw materials and finished goods. The report is forwarded to the Production Control Department.

:. Attachment No. Raw Materials, Intermediates and ...

The movement of materials across the site is shown in Appendix Material Flow. All physical movements of material and quantity will be reflected immediately on the SAP system once the transfer orders created for movement of material to required locations are confirmed.

Automated Material Handling System Based On the PLC

This Automated material handling system is composed of an entry/exit bay of metallic parts, a three axis arm, robots actuators, sensors, drivers and an entry/exit bay of boxes.

Flow Pattern of Materials: Meaning and Types

"Flow Pattern" means the system to be adopted, for the movement of raw materials, from the beginning and up to the end of manufacturing. The overallobjective of the 'Flow Pattern' is to plan for the economical movement of the raw materials throughout the plant.

CHAPTER2 INTRODUCTION TO MATERIALS MANAGEMENT

• Gossom (1999) indicates that a material management system should have standard procedures for planning, expediting, transportation, receipt, and storage to ensure and efficient system for materials control. • Cavinato (1994) states that material management involves the control of the flow .

Cement Manufacturing Process Explained Lion Bulk Handling

Cement Manufacturing Process Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix. Production of cement completes after passing of raw materials from the ...

Augmenting an Inbound Raw Material Handling System of .

raw material unloading process is provided in Figure 2. Figure 2: Raw Material Unloading Process The adequacy of the current facilities for handling the increased arrival of raw materials needed to be investigated and in case of inadequacy, appropriate changes needed to be proposed, so that the system

Raw Material In Iron Making SlideShare

Apr 03, 2010· Iron Ore Section Material Handling System Raw Materials are Stored and transported inside steel plant and fed into Blast Furnace through material handling system 15. Flow Diagram Blast Furnace Iron Ore Coal Coke Oven Plant Coke 16.

Supplier Quality Management Production Part Approval ...

should have the type of quality system that develops all of the requirements of a ... Bulk material: New source of raw material 10. Change in product appearance attributes 11. Change in production process or method ... Production Part Approval Process (PPAP).

Materials Handling: Functions, Objectives and Principles

Systems concept for materials handling means, adopting a materials handling system from overall optimisation point of view. This means that it is not necessary to buy the latest materials handling equipment, materials handling engineer must put all the elements of the system together to see whether it is profitable for the enterprise.

The Principles of Material Handling BP Automation

Mechanical handling of materials from inbound raw material to outgoing finished product help reduce production cost and safety concerns. At BP Automation, we design and manufacture automated material handling systems for a broad range of industries.

:. Attachment No. Raw Materials, Intermediates and ...

Raw material and packaging for use in pharmaceutical manufacturing, Work in Progress (WIP) all finished goods are stored in the Pharma Warehouse. The Chemical Warehouse is used for the storage of solid raw materials, intermediates packaging for use in API manufacture, which require storage indoors.

Material Handling System Aluminum Extrusion Handling ...

Material Handling System With the support of our huge vendor base, we are able to import and export a wide assembly of Handling Systems . Under this array, we offer Belt Conveyor, Belt Felt For Handling Systems .

Global Warehousing, Handling and Storage Quality .

The quality management system documentation shall include: Documented procedures for the warehousing, handling, storage, and transportation of Mondelēz International materials and products. Documented procedures for the Control of Documents and Records related to Mondelēz

Raw Material Handling Equipment Maida Handling System ...

Raw Material Handling Equipment Our company is engaged in developing excellent range of Raw Material Handling Equipment, which is manufactured from high grade stainless steel and installed in several bakery and food processing industry.

Material Receiving Process Flow Chart

Warehouse flowchart if useful for describing any raw materials, packing materials, spare parts, components or finished goods associated with agriculture, manufacturing and production at .

Raw Material Storage And Handling System Flow Diagram ...

Raw material Storage and Handling system flow diagram : Raw material Storage and Handling system flow diagram truck Silos Intermediate storage Screw conveyor Or .

Raw material warehouse SlideShare

Apr 26, 2013· raw material warehouse 1. steps involved in rawmaterial warehouse receiving sampling storing dispensing 2. receiving of raw material raw material is supplied by vendors byplacing order after receiving the raw material check the"observation on pack" segregate the raw material according tobatch number pre entry cleaning of raw material by vaccumcleaner weighing of the raw material

SOP for Handling and Storage of Raw Packing Material ...

SOP for Handling and Storage of Raw Packing Material Standard operating procedure to store the Raw Material and Packing Material in stores quarantine area after receiving the material as per the storage procedure in pharmaceutical industries.

OPERATIONAL SIMULATION MODEL OF THE RAW .

the system was made in the specification. A detailed raw material handling flowchart was prepared, where origins and destinations of all the raw material in the system were represented, as well as the equipment comprising the system, and data for entrance and exit of the model was defined.

Latest Posts

- معدات تعدين خام الحديد مصر

- سيور ناقلة مستعملة مصر

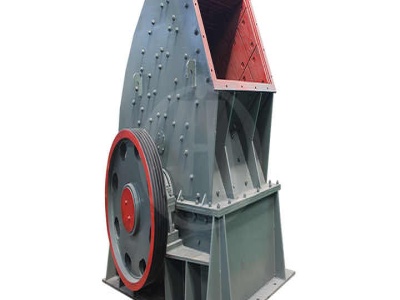

- الفك الابتدائي سعر كسارة للبيع محطم مصنع

- تاجر قطع غيار كسارة مصر

- شركة منتجات كسارة

- معالجة تعدين النحاس في اليمن

- مطاحن الدقيق المصنعة في تركيا

- التحقيق سحق المحمول

- تكلفة شاشات الاهتزاز

- تستخدم آلة كسارة الحجر الثابتة في عمان للبيع

- jual liner الكاراتيه مطحنة الكرة bekas

- الأجزاء الرئيسية كسارة مخروطية الرأس القياسية قصيرة

- أنواع أسعار الكسارات الأولية

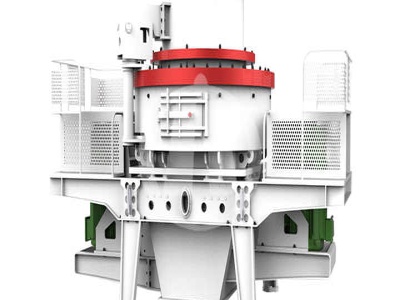

- ما هي كسارة مخروطية محمولة

- مصنع صغير لتعدين الذهب للبيع

- jalan batu menghancurkan dan menyaring tanaman

- stone crusher arbra

- ball mill in refining in nalco

- coal processing industry

- axil play in trunion bearing of raw mill

- quarry breaker nigiera

- low price small size mill grinding sale in coimbatore

- rotor centrifugal crusher rsm price

- spesifikasi stone crusher mobile

- short head crusher video

- youtube mesin cruk as grinding

- thorium reactor fluoride

- centrifuge cyclone placer gold mining portable mining equipment

- kmc peanut china company

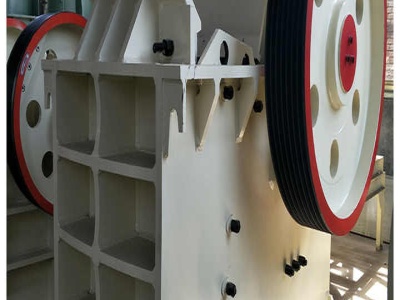

- jaw crusher x 4