rol crusher

Roll crusher | Article about roll crusher by The Free ...

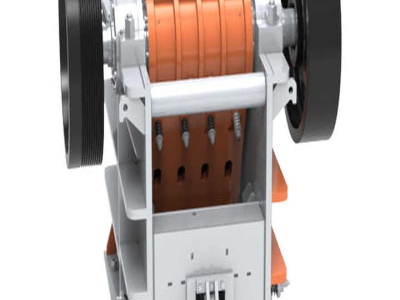

A twin jaw crusher can often do the work of a jaw crusher and a roll crusher. Tenders are invited for Installation Of Double Roll Crusher, Make Humbold Wedag In Place Of Damaged Single Roll Crusher For Crushing The Raw Coal To 80Mm Size At Raw Coal Section At Kathara Washery.

Roll Crushers ThomasNet

Prater Industries Bolingbrook, IL. Manufacturer of standard custom crushers including roll crushers rotary crushers. Features include double roll crusher with positive uniform crushing, sealed design, ball bearing mounted shafts, tempered replaceable shear bar, feed control gate, clean out door 304 stainless steel construction.

HAZEMAG ROLL CRUSHER | HRC

Materials to be crushed become more and more difficult in terms of handling, high throughput capacities are required and the energy input is a key focus. Therefore the application of energyefficient roll crusher with high throughput rates becomes more and more important from the economic and ecologic point of .

HAZEMAG Products

Feeder Breaker | HFB. The HAZEMAG Feeder Breaker HFB is a complete horizontal roll crusher plant, which works according to the fieldproven principle of crushing in the horizontal material flow.

Sandvik Hybrid Crusher Series — Sandvik Mining and Rock ...

Sandvik hybrid crushers combine the advantages of different roll crusher systems, and are an ideal solution for primary, secondary and tertiary crushing applications. They have specially designed teeth, hydraulic gap adjustment, overload protection, and a scraper system perfect for dealing with sticky materials. These machines can work at capacities of up to 12,000 metric tons per hour ...

Roll Crusher | Products Suppliers | Engineering360

Effect of roll clearance on percent of unbroken particles in roll crusher product . Enabling Tool for Innovative Glass Applications Final Report Once it was determined that a roll crusher would be used in the initial size reduction of the glass, the challenge was in establishing the gradation of size fractions which, while minimizing the ...

Roller crusher, Roll grinder All industrial ...

MACSALAB Rolls Crusher size '0' and '1' are designed for secondary reduction after jaw crushing. These smooth roll crushers will rapidly reduce coal, ore .

Glass Crushers | Northern California Compactors Inc

Glass Crushers. Glass crushers are machines designed with the aim of pulverizing glass to aid in the recycling process. Waste glass comes from various sources, in the form of glass sheets, containers, jars and bottles, and can be recycled with the help of a glass crusher to avoid generating new glass, which in turn saves energy.

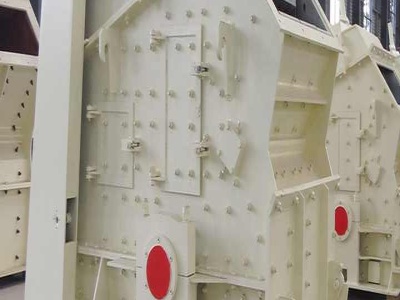

Double Roll Crusher – CPC GmbH – Crushing Processing

CPC Double Roll Crusher Application. Coarse size reduction of hard and mediumhard material (lime stone, magnesia, salt, fertilizer, coal etc.) Throughput up to mt/hr, depending on material characteristic and particle size; Feed material size up to mm, product particle size from 10mm to 300mm possible, according customers demand

Reliable Toothed Roll Crusher Fote Machinery(FTM)

Description of Toothed Crusher: Toothed crusher is driven by one or more motors, and then, the pulley on its both sides drives the rolls turn into opposite direction, finally, the materials lower than the two automatic roll gap fall down and are crushed on the rolls to achieve the desired grain size.

Single Roll Crushers Shredders for Scrap Materials

Single Roll Crusher. American Pulverizer Company Single Roll Crushers provide everything you want out of an efficient machine. And everything you want in it. Single Roll Crushers are the product of over a century of experience. Each is designed to the highest engineering and construction materials standards.

Roll Crusher,China Roll CrusherHongxing Machinery

Roll Crusher. Mainly used for the crushing of medium or lowerhardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial production. Click here to get Roll Crusher and parts' price.

Roll Crusher at Best Price in India

we manufacture double and triple roll crusher with heavy duty rollers, gear drives, gap adjusting both mechanical and hydraulic, from a range of 5 to 200 Products like minerals, herbs, edibles, rubber, tannery items are crushed through it.

Roller Crusher, Double Toothed Roll Crusher, Smooth Roll ...

Performances of double roll crusher. 1. Users can take the roller crusher to crush mineral ores with medium harness. Since the shape, size and array of teeth on roller surface can be changed with the property of raw material, either the secondary or tertiary crushing is easy to realize.

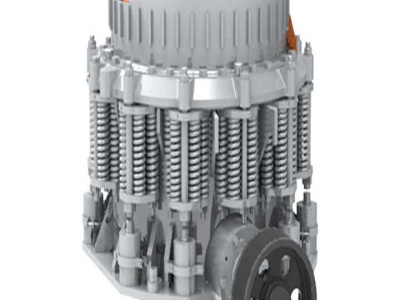

Cedarapids Static Cone crushers

MVP550X The Cedarapids® MVP550X Cone Crusher features a new mantle nut retention system, bowl float monitoring system and many more new features. TC1000 The TC Cone Crusher provides an excellent reduction and product cubicity for the production of high .

Stone Crusher Machine YuKuang Machinery

We offer all kinds of crusher such as stone crusher, rock crusher, hammer crusher, impact crusher, cone crusher, mobile crusher, jaw crusher etc. Tel: +.

New and Used Cone Crushers for Sale | Savona Equipment

Cone Crushers. Savona Equipment is a cone crusher supplier worldwide. Cone crushers are used in large primary ore crushing, secondary, and tertiary fine material as well as complete aggregate cone crushing lines. We also have cone crusher parts for sale but they are subject to availability. With the rapid development of mining technology,...

Roll Crusher

Simatec Roll Crusher: The double roll crusher with smooth rolls is used for secondary or tertiary crushing of middle to small sized materials. A key benefit of the double roll crusher is the ability to produce a narrow particle size distribution, thus minimizing the production of undesired product sizes.

Double Roll Crusher, 13mm Particle Size Gilson Co.

Topsize is approximately 13mm and final fineness typically passes a (2mm) opening, depending on material type. Roll Crushers work well in preparing samples for further fine reduction using a pulverizer. Output size is controlled by adjusting the gap between the rollers using a hand lever.

What are the differences between a jaw crusher vs a cone ...

Mar 04, 2017· The jaw crusher is normally used as primary crusher. It is mostly suitable for hard materials and the wear cost are lower than the impact or cone crusher. As for cone crusher it is recommended for hard materials as a secondary crusher where you can get fractions from 0–32mm.

EFFICIENT

THE FIELDS OF APPLICATION Double roll crushers are used for both, primary and secondary crushing. They guarantee a strictly de fined final grain size with a minimum of fine grains.

Global Single Roll Crusher Market Outlook, Geographical ...

May 20, 2019· Single Roll Crusher Market is drafted after detailed analysis of various key market factors like market size, market trends, market challenges key drivers driving the Single Roll Crusher data like CAGR value, working capital, enterprise value book value of leading companies is also available in the report to gain insight into the Single Roll Crusher Market space.

Latest Posts

- مصنع الكرة مطحنة في مومباي

- كرة صغيرة آلة الصحافة

- المحمولة صخرة محطم المملكة العربية السعودية

- المطاط الحزام الناقل جزيره العرب السعودي

- غسل الرمل خط الانتاج

- طحن الاسمنت مصنع مطحنة الكرة

- السودان صناعة التعدين

- انشاء معمل لغسيل الرمل

- كسارات الفك من المملكة العربية السعودية

- آلة كسارة الذهب مصر للإيجار من جهة ثانية

- كسارة خام صغيرة للسيارات للمنزل

- كسارة فحم صغيرة للبيع في مصر

- معدات التكسير

- تستخدم مصر معدات التكسير المتنقلة 100tph

- محامل محطم

- buffalo county approves rural mondovi frac sand

- quality parameter of cement mill

- nozzle grinding crusher

- crusher stone use germany dec

- what metal is in rock crushers

- used portable crusher plant for sale dubai

- crushers of elysium

- indonesia rock breaker distributor crusher mills cone

- gyratory crusher equipment specifi ion

- besan plant impact pulverizer branded

- machine face grinding

- introduction of grinding machine

- milling machine bridgeport 1es

- truck primary crusher model autocad

- mineral equipment processing supplier india